Press release

AIJU researches on the influence of processing conditions on Migration

The study will determine how the processing conditions and material issues affect in the foodstuff migrationChildren’s products intended for use at feeding times (tableware and cutlery, cups and food containers) are subject to strict safety standards. Furthermore, complementary regulations related to the compliance of plastic materials in contact with foodstuffs (Regulation no 10/2011) must be observed.

Migration from the plastic container to foodstuffs can be influenced by several factors relating to usage, and these have been studied in-depth. Notwithstanding the fact that some studies show that processing conditions also have considerable influence, there are no studies which thoroughly analyse the influence of the processing conditions on migration even though they notably affect the material characteristics and structure, among others.

That is why AIJU is going to undertake a detailed study on the influence that different processing conditions have on the migration of organic and inorganic substances which are used to produce children’s foodstuff articles. Within the study the necessary testing methods are being developed for the identification, and where necessary specific quantification of any migrating substances.

As the development of the project is aimed at the traditional products manufacturing sector, it will made available for enterprises from the plastic & infant industries new resources for the development of safer products in such a way that it will help to bring about the compliance with current legislation relating to global migration.

This project is funded by IMPIVA within the Strategic Development Programme (Expedient IMDEEA/2011/25) and co-funded with FEDER funds.

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the Spanish geographic centre for the manufacture of toys. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is to transfer and allow toy manufacturers access to the knowledge of new technologies in order to improve their competitivity, while offering technological and financial assessment and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 75 professionals who develop their work in the different departments that make up AIJU. Moreover, this organization has the required infrastructure to manage the different activities it undertakes.

The department intended to carry out these tasks is that of Product Development – Laboratory Department, specifically the Processing and Materials area, in close collaboration with the Chemical Area. These areas have several research lines for the study of materials, process monitoring, materials in contact with foodstuffs and the development of test methodologies for the analysis of organic and inorganic toxic compounds, among others.

AIJU has been accredited by ENAC for the carrying out of global migration tests on all simulants for food contact plastic materials since 2005. Additionally, it is an active member of the Technological Platform for Traditional Manufacturing Sectors, EuMAT and Manufuture, among others, and member of the “Materials” group promoted by REDIT, the RDT Centres of IMPIVA’s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed legislation as well as new safety criteria for toys, with participation in several proficiency testing schemes both, on a National and European Level, between it is relevant the Spanish Technical Committee AEN/CTN 172/SC2 of childcare articles. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

Would you like further information, please visit: www.aiju.info.

AIJU

Avda. de la Industria, 23

03440 Ibi (Alicante)

Product Development - Laboratory Dpt. - Materials & Processes area

Tel. 965554475 (Ext. 217)

e-mail: proyectos@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AIJU researches on the influence of processing conditions on Migration here

News-ID: 181921 • Views: …

More Releases from AIJU

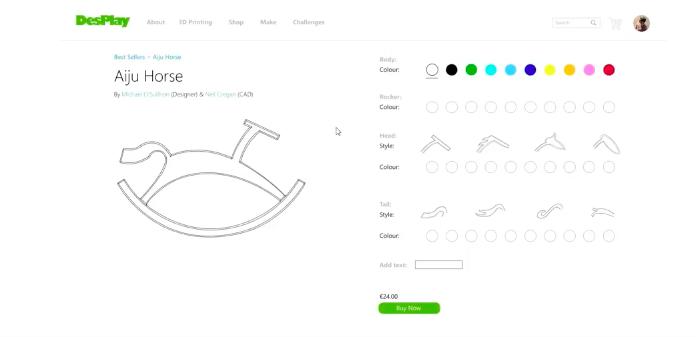

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for IMPIVA

Toys Personalized Decoration Technologies

“Water Printing” and “Digital Printing” have shown to be applicable for achieving the objective.

Over the last two years AIJU has developed the Project Decoratoy, aimed at the study and applicability of diverse decoration techniques for the personalized decoration of three dimensional plastic pieces, mainly in the toy sector, carrying out decoration testing using several technologies. Those having showed great applicability are Water Printing, Digital Printing and Transference Films, among others.

Water…

“Water Printing” Application for the Decoration of Toys

The research results, carried out by AIJU, demonstrate the possibilities for this application technique within the personalized decoration of 3D pieces.

This technique will allow the decoration of a large amount of products with different geometric shapes in an efficient and versatile way. Moreover, after several baths, a 360º surface covering of the piece to be decorated can be achieved, with a good finish and that includes any small grooves the…

AIJU & AITEX collaborate to achieve the improvement of properties in polymeric s …

In general, polymeric materials are characterised by having a low surface energy, caused by the absence of polar groups within the polymer structure. It is often necessary to modify these properties to increase their surface energy and thus, improve their moisture absorption characteristics. These treatments are fundamentally directed at activating the surface by inserting polar specimens, or at provoking modifications to the surface topography, in such a way…

AIJU researches customized and automated decoration for toys

AIJU is researching the tools available for the customized decoration of toys, with the aim of thoroughly studying them and their applications, in order to optimize their usefulness in such a way that they could be used for the personalized decoration of toys, according to the final users’ or consumers’ requirements.

This research funded by IMPIVA and co-funded by FEDER funds, within its R&D programme (Expedient no. IMIDIC/2010/56), has arisen due…

AIJU researches on the best properties of playground surfacing

The high-impact capacity can be improved by optimising the design factors on rubber surfacing installed in our playgrounds.

Rubber surfacing is an environmentally sustainable product, as a high percentage of recycled rubber from tyres no longer used is used in the manufacture of this material. This kind of material is perfect for playground surfacing, due to its impact mitigation properties in case of falling from playground equipment, such as swings, seesaws,…

AIJU develops a new conductive plastic formulation that improves the Electromagn …

The integration of this new formulation within electronic toys will avoid the electromagnetic interference that these toys generate on other electronics devices.

Electrical and electronic toys are of considerable relevance within the sector and due to the increase in videogames and similar products it is a progressively increasing sector. These types of toys produce interference on the proper functioning of other electronic appliances due to the magnetic interference they produce, and…