Press release

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing of rubber articles and expanded EVA and the synthesis of catalysts for the sustainable production of hydrogen. Nevertheless, the zinc oxide (ZnO) has a great quantity of applications within the pharmaceutical and cosmetic industry, the metallurgical industry, the industry of electrical components and batteries and other manufacturing industries of mirrors, coins, dental cements, paintings, etc. These industries will achieve first quality ZnO from industrial waste.

Nowadays, there is not any kind of technique that allows the obtention of ZnO from this residual origin at industrial scale. The recycling of zamak is usually employed to obtain lower quality ingots, which generates harmful atmospheric emissions. On the other side, it is worthwhile for the managing organisations depositing this waste in controlled landfills, which results in a big amount of waste while the potential use of resources contained in it is wasted.

At present, ZnO is obtained from zincite, a nature derived mineral. With this project, it will be achieved from an industrial waste in a compact pilot plant, what will allow to tackle environmental problems of a different kind.

Waste aimed to be treated is mainly sludge from vibration and slag from smelting, which come from zamak processing industries like the automotive industry, manufacturing companies of electrical engineering equipment, the building industry, furniture, electrical appliances, office equipment, measurement equipment, toys, optics, clock making and a large etcetera.

According to the European Foundry Association, the industry of transformation of zamak alloys generates in Europe approximately 1 million tons of waste, mainly in form of sludge from vibration and slag from smelting. Estimations carried out for the project show that issued waste could be reduced up to 425.000 tons/year, which exceeds in around 100.000 tons the waste production issued in Spain.

This waste, largely considered dangerous, is not given economic value, since it is deposited in safety landfills. Consequently it generates, apart from the related environmental harm, additional costs due to its management and disposal. These costs are mainly covered by the zamak processing industries, whose current costs related to waste management, with this action, could be reduced up to 35%.

Enrique Añó, general co-coordinator of the project, establishes that the results of this project “will allow reusing industrial waste of the non-ferrous metal transformation sectors, which will minimise its environmental impact and the costs related to waste management”. He adds that “nowadays there are not technological developments at industrial scale economically feasible to valorise this waste and, consequently, it is more profitable to send it to landfills”. Giving it value by this action, “will allow to obtain ZnO without causing CO2 emissions and its expansion on the market will enable using a more environmentally-sustainable ZnO from industrial waste”. Additionally, he says that “one of the project actions will demonstrate the feasibility of the ZnO obtained to several industrial applications, as activator in the rubber vulcanization, EVA accelerator and chemical catalysis”.

Rubén Beneito, the other co-coordinator of the project, states that “the use of the ZnO obtained thanks to the GREENZO project as catalytic support for the production of hydrogen from ethanol waste, contributes to the European Commission objectives on the shortening of dependence on fossil fuels, which will open a door towards a new production process of totally-renewable hydrogen, including the catalyst itself”.

This project, which will be developed in 3 years, is funded by the European Commission through the funding instrument LIFE13 ENV/ES/000173. Its kick-off meeting, coordinated by AIJU and with the participation of the research centre ITQ-CSIC and the companies WORTEUROPE and CAUCHOS KAREY, was held last June 18th at AIJU’s facilities, where the basis to reach the objectives aimed was established.

The Technological Institute of Children’s Products and Leisure (AIJU) was founded in June 1985 as an initiative of the Valencian SMEs Institute (IMPIVA) and the Ministry of Industry & Energy (MINER), with the aim to support the development of the toy industry. Nowadays, AIJU has spread its activity and it is a reference in all the industrial sectors of children’s products and leisure; AIJU offers high technological value services to organisations working in different fields.

It is located in Ibi, Alicante, and is a non-profit organisation focused on research & development, technological innovation, the competitiveness increasing and the quality improvement.

The services that AIJU offers to more than 450 associated are focused in 6 specific areas: innovation and sustainability management, children & leisure consumers, product development and ITCs, technologies, safety and testing, training and information. The technical unit in charge of the activities displayed is the Innovation and Sustainability one, in particular the Environment and Energy areas. These areas have different development lines. Among those related to the current action we can find the following:

- Research, development, innovation and sustainability (I+D+I+S) of management systems of industrial waste / zero waste.

- Research on catalytic reforming processes for the production of renewable hydrogen.

Among others, AIJU is a member of the Spanish Technological Platform on Environmental Technologies (PLANETA) and the Spanish Platform of Hydrogen and Fuel Cells. At European level, AIJU is funding partner of the “New European Research Grouping in Hydrogen and fuel cells” (N.ERGHY).

For further information, please visit: www.aiju.info.

AIJU

Avda. de la Industria, 23

03440 Ibi

Tel. +34965554475

e-mail: proyectos@aiju.info

Pepi Galvañ

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New pilot plant for the obtention of zinc oxide from zamak waste here

News-ID: 290895 • Views: …

More Releases from AIJU

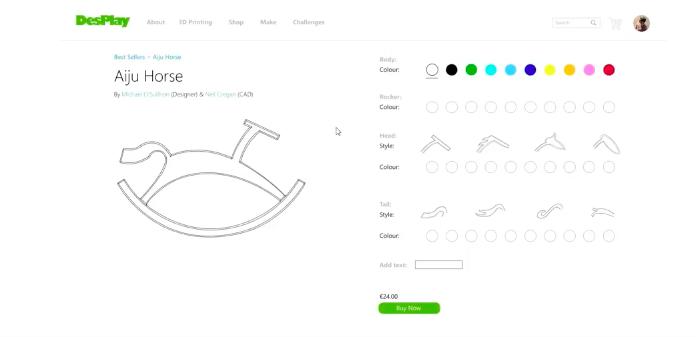

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

More Releases for ZnO

Middle Temperature ZnO Desulfurizer Market Size Report 2025

Global Info Research announces the release of the report "Global Middle Temperature ZnO Desulfurizer Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031". This report provides a detailed overview of the Middle Temperature ZnO Desulfurizer market scenario, including a thorough analysis of the Middle Temperature ZnO Desulfurizer market size, sales quantity, average price, revenue, gross margin and market share.The Middle Temperature ZnO Desulfurizer report provides an in-depth analysis…

Nanometer ZnO Market: Competitive Dynamics & Global Outlook 2025

LP INFORMATION recently released a research report on the Nanometer ZnO market analysis and elaborate the industry coverage, current market competitive status, and market outlook and forecast by 2025. Moreover, it categorizes the global Nanometer ZnOmarket by key players, product type, applications and regions,etc.

The main objective of this market research is to help the readers understand the structure of Nanometer ZnOmarket, market definition, overview, industry opportunities and trends, investment…

Global ZnO Nanoparticles Market Outlook Data Analysis 2020-2025

This report also researches and evaluates the impact of Covid-19 outbreak on the ZnO Nanoparticles industry, involving potential opportunity and challenges, drivers and risks. We present the impact assessment of Covid-19 effects on ZnO Nanoparticles and market growth forecast based on different scenario (optimistic, pessimistic, very optimistic, most likely etc.).

GLOBAL INFO RESEARCH has recently published a research report titled, [Global ZnO Nanoparticles Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025] assessing various factors…

Global ZnO Nanoparticles Market Huge Growth Opportunity between 2020-2025

LP INFORMATION recently released a research report on the ZnO Nanoparticles market analysis, which studies the ZnO Nanoparticles's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "ZnO Nanoparticles Market 2020-2025" Research Report categorizes the global ZnO Nanoparticles market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth…

Global ZnO Nanoparticles Market Huge Growth Opportunity between 2020-2025

LP INFORMATION recently released a research report on the ZnO Nanoparticles market analysis, which studies the ZnO Nanoparticles's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "ZnO Nanoparticles Market 2020-2025" Research Report categorizes the global ZnO Nanoparticles market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share, growth…

Particle Grade ZnO Market || Research Report, Growth Forecast 2020-2030

This research study on "Particle Grade ZnO market" reports offers the comparative assessment of Particle Grade ZnO market and consist of Historical data, Significance, statistical data, size & share, Market Price & Demand, Business overview, Market Analysis By Product and Market Trends by Key Players. This Particle Grade ZnO Market is Segmented in two type on the basis of type of materials and end-users. It has global market covered in…