Press release

Toys Personalized Decoration Technologies

“Water Printing” and “Digital Printing” have shown to be applicable for achieving the objective.Over the last two years AIJU has developed the Project Decoratoy, aimed at the study and applicability of diverse decoration techniques for the personalized decoration of three dimensional plastic pieces, mainly in the toy sector, carrying out decoration testing using several technologies. Those having showed great applicability are Water Printing, Digital Printing and Transference Films, among others.

Water printing consists of printing the image to be used to decorate the piece on a water soluble Polyvinyl Alcohol (PVA) film. This film is placed in an immersion tank, filled with water, in such a way that the PVA film makes direct contact with water and is dissolved while the ink stays floating on the water. Next, the ink is sprayed with a chemical activator and the sample is introduced into the water, so that the ink covers the sample and adheres to the surface. Finally, once the surfaces of the decorated piece are clean and dry, a transparent coating is applied to increase the durability of the piece and its resistance to weathering.

Digital Printing consists of the direct reproduction of a digital file on a physical piece, generally 2D. When working with this technique with three dimensional geometries two difficulties arise: the distance and the inclination relative to the impression head and the substrate. The technology has shown to be interesting and valid for the personalized decorations of pieces in which the maximum distance is around 12 mm between the highest and lowest points of the piece geometry and the relative angle between the head and the face of the pieces does not exceed 30º.

Regarding the vinyl transference films with digital impression, there are references that it can be adapted to 3D surfaces with great flexibility. For the most complex surfaces, it could be necessary to apply heat so that it adapts perfectly to the piece’s geometry.

Previously, several techniques were researched in-depth. Pad Printing (and its new system with sealed ink cups and microprocessor controllers), Serigraphic Printing (that requires the development of the UV curing of inks on difficult substrates such as polyolefins, acetals and other thermoplastic resins), and Offset Printing (which permits double face printing). All of them allow the use of multiple colours, to obtain improved productivity, a better register and further versatility. Other novelties use laser marking with this aim, although they still have some restrictions in order to obtain colour and shine adjustments, therefore they are used in non-aesthetic applications.

Miguel Angel Leon, the technician in charge of the project says that, “this project offers us a great challenge, but it is being undertaken with the conviction that the toy industry is going to be able to adapt to systems with the desired aim, being conscious of their advantages and inconveniences, scopes and limitations, in a way that the toy industry will be able to apply the best option for each specific case.”

This research is funded by IMPIVA and co-funded by FEDER funds, within its R&D programme (Expedient no. IMIDIC/2010/56), arose due to the concern shown by organisations in the sector, over new tendencies observed within their specific fields, that are characterized by an increasing demand for personalized products, in shorter delivery times, and small production runs.

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the Spanish geographic centre for the manufacture of toys. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is both, to transfer and allow toy manufacturers access to the knowledge of new technologies in order to improve their competitivity, while offering technological and financial assessment, and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 77 professionals who develop their work in the different departments that make up AIJU. Besides, this organization is provided with the required infrastructure to manage the different activities it undertakes.

The department intended to carry out these tasks is that of Product Development – Laboratory Department, specifically the Processing and Materials area. This area has several research lines for the development of new processes, among them the development of new decorative processes within the sector as well as pre-treatments for their optimisation. Additionally, this area is devoted to new materials development for both, traditional and rapid manufacturing technologies. The area carrying out this project has been working closely with the Rapid Manufacturing area for 10 years now with the objective of reaching final material sets.

AIJU is an active member of the Rapid Manufacturing European Platform and the Spanish mirror led by ASERM, the Spanish Rapid Manufacturing Association. It is also a member of EuMAT and Manufuture and a member of the “Materials” group promoted by REDIT, the RDT Centres of IMPIVA’s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed legislation as well as new safety criteria for toys, with participation in several proficiency testing schemes both, on a National and European Level. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

AIJU

Avda. de la Industria, 23

03440 Ibi (Alicante)

Spain

Tel. +34 965554475

e-mail: proyectos@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Toys Personalized Decoration Technologies here

News-ID: 214391 • Views: …

More Releases from AIJU

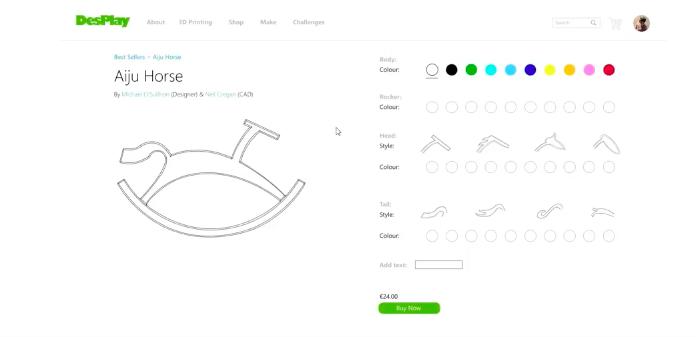

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Printing

Printing Shop Singapore: A Comprehensive Guide to Shirt Printing and Name Card P …

Image: https://www.getnews.info/uploads/77eaa7fd01d4e9a00273658898560459.png

In Singapore's bustling metropolis, the printing industry thrives, catering to a wide array of needs from corporate branding to personal projects. Among the numerous printing services available, t shirt printing [https://printvolution.sg/product/wearables/cotton-shirt/] and name card printing stand out for popularity and necessity. PrintVolution, a premier printing shop in Singapore [https://printvolution.sg/], offers top-notch services in these areas, ensuring high-quality results for all clients.

Shirt Printing Singapore

Shirt printing has become increasingly popular in…

Commercial Printing Services Market Size, Share Analysis, Trends, Growth And For …

The Business Research Company has updated its global market reports with latest data for 2024 and projections up to 2033

The Business Research Company presents an extensive market research report on the ""Commercial Printing Services Global Market Report 2024,"" furnishing businesses with a competitive edge through a detailed examination of the market structure, encompassing estimates for various segments and sub-segments.

Furthermore, the report highlights on emerging trends, significant drivers, challenges, and opportunities,…

Security Printing Market Security Printing Market

Security Printing Market: An Overview

Increased cases of forgery and counterfeiting practices are anticipated to drive the security printing market over the forecast period. Counterfeiting practices are particularly prevalent in bank notes, passports, postage stamps, identity cards, stock certificates, and contraband. Security printing helps in prevention of tampering and forgery of the instruments mentioned above.

Obtain Report Details @ https://www.transparencymarketresearch.com/security-printing-market.html

The key end market verticals in security printing market includes Banking, Financial Services…

Retail Security Tags Market by Technology (Barcode, Radio Frequency Identificati …

Retail security tags are used to attach a single or multiple products to identify, track, and count products. These are used by various companies and retail outlets to count and trace products. These offer benefits, such as automation, cost efficiency, security, and accuracy, in tracking inventory through supply chain network and retail environment.

The global retail security tags market is driven by rise in security measures in retail industry and decline…

Textile Printing Machine Market by Type (Rotary screen textile printing, Automat …

According to a new report published by Allied Market Research, titled, Textile Printing Machinery by Product type and Application: Global Opportunity Analysis and Industry Forecast, 2017-2023, the textile printing machinery market was valued at $7,309 million in 2016, and is projected to reach at $10,220 million by 2023, growing at a CAGR of 5.0% from 2017 to 2023. Asia-Pacific is expected to be the leading contributor to the global textile…

Global UV Cured Printing Inks Market By Application – Flexographic, Gravure Pr …

Researchmoz added Most up-to-date research on "Global UV Cured Printing Inks Market By Application – Flexographic, Gravure Printing, Offset Printing, Digital Printing and Screen Printing" to its huge collection of research reports.

Global UV Cured Printing Inks market size will increase to Million US$ by 2025, from Million US$ in 2017, at a CAGR of during the forecast period. In this study, 2017 has been considered as the base year and…