Press release

AIJU & AITEX collaborate to achieve the improvement of properties in polymeric substrates by means of Plasma techniques

In general, polymeric materials are characterised by having a low surface energy, caused by the absence of polar groups within the polymer structure. It is often necessary to modify these properties to increase their surface energy and thus, improve their moisture absorption characteristics. These treatments are fundamentally directed at activating the surface by inserting polar specimens, or at provoking modifications to the surface topography, in such a way that there is an increase in roughness.The treatment is carried out by applying a process (physical or chemical) that modifies the surface of a material by improving its surface properties, such as painting, moisture absorption, adhesion, etc. without affecting the general properties of the treated material. There are different plasma treatments applicable, according to the article to be treated and the desired properties. All of them are dry treatments, which use ecological technology, and can suppose great advances in the improvement of the technical performance of final products, and the minimization of processing problems caused by the working of raw materials.

That is why the strategic project, “Research and development for the improvement of the solidity of finishing by plasma technologies,” supported by the Conselleria d’Indústria, Comerç i Innovació (ref. INIDIV/2010/63) and co-funded with FEDER funds, has the objective of consolidating the use of several of the existent technologies for specific applications in the toy and textile sectors. This project, led by the toy company INJUSA, is being developed by a Spanish R&D consortium formed by two RDTs and ten companies from the plastic, textile and children’s products sectors, and will add value to the products of these traditional and relevant sectors within the Valencian Community.

The characterization of the changes achieved by plasma treatment on different surfaces and materials, and the knowledge of the acting mechanism, are the main points where the work is focused. Two parallel working lines have been established: Surface Activation or plasma treatments for the improvement of the solidity of finishing; and Plasmapolimerization or plasma treatments for the deposition of thin functional layers.

Once these treatments were applied to the test specimens, made from the different materials studied (standard and high density polyethylene, polypropylene, impact polystyrene, polycarbonate, PET, natural and synthetic fibres, flexible substrates - tissues, membranes, foams, etc.) the characterization of the surface modification of the treated test specimens and the chemical modification that occurred on their surface was conducted. The thermal and mechanical tests for the substrates characterization were also carried out to know their properties and thus, further understand the changes that occurred on the surface.

Regarding the treated textile materials, the application of low pressure plasma technologies by corona discharge also led to an increase in their hydrophilicity. The degradation potential of textiles after the treatment was characterized establishing that in treatments lasting less than 5 minutes there is no degradation of the surface.

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the Spanish geographic centre for the manufacture of toys. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is to transfer and allow toy manufacturers access to the knowledge of new technologies in order to improve their competitivity, while offering technological and financial assessment and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 75 professionals who develop their work in the different departments that make up AIJU. Besides, this organization is provided with the required infrastructure to manage the different activities it undertakes.

The department intended to carry out these tasks is that of Product Development – Laboratory Department, specifically the Processing and Materials area. This area has several research lines for the development of new decoration processes as well as pre-treatments in order to optimise such processes. Additionally, this department is working on the development of new materials, for both traditional processes and those of Rapid Manufacturing.

AIJU is an active member of the Rapid Manufacturing European Platform and the Spanish mirror led by ASERM, the Spanish Rapid Manufacturing Association. It is also member of EuMAT and Manufuture. AIJU is the coordinator of the working group “Rapid Prototyping Proposal SP3 (materials) Lab” and member of the “Materials” group promoted by REDIT, the RDT Centres of IMPIVA’s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed legislation as well as new safety criteria for toys, with participation in several proficiency testing schemes both, on a National and European Level. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

Find further information at: www.aiju.info.

AIJU

Avda. de la Industria, 23

03440 Ibi

Tel. 965554475

e-mail: proyectos@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AIJU & AITEX collaborate to achieve the improvement of properties in polymeric substrates by means of Plasma techniques here

News-ID: 164587 • Views: …

More Releases from AIJU

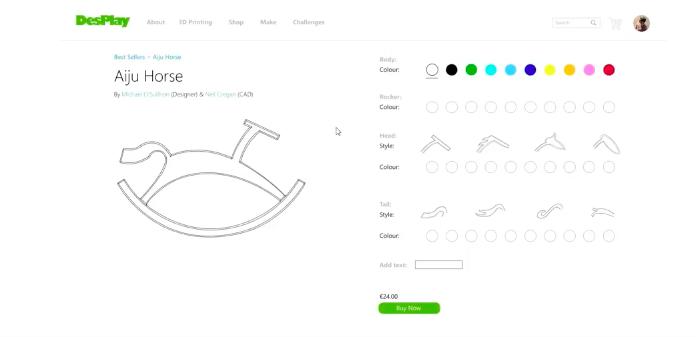

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Plasma

Blood Plasma Freezers Market Safeguarding Plasma Derivatives: Blood Plasma Freez …

Global Blood Plasma Freezers Market Worth $772.0 Mn by 2031 - Exclusive Report by InsightAce Analytic Pvt. Ltd.

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Blood Plasma Freezers Market- (By Type (Manual Defrost, Automatic Defrost), By Application (Hospital, Laboratory), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Blood Plasma Freezers Market…

Contract Plasma Coating Service Market Analysis, Size, Share, Trends, Growth And …

The Global Contract Plasma Coating Service Market report is added by WMR to its database to offer a complete assessment of the factors influencing an overall market growth trend. The research covers significant data and proves to be a handy resource document for industry experts. The research is a perfect balance bridging both qualitative and quantitative information of this market. Quantitative statistics with qualitative reasoning related to market size, share,…

Cold Plasma Market Analysis By Top Keyplayers - Plasma Air, Atmospheric plasma t …

The "Cold Plasma Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Cold Plasma Market, 2024-2031

Verified Market Research's most recent report, "Cold Plasma Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030," provides an in-depth examination…

Contract Plasma Coating Service Market Revenue Sizing Outlook Appears Bright| He …

The Latest research study released by HTF MI "Global Contract Plasma Coating Service Market with 120+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know-how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint, and status. Understanding the segments helps in identifying the importance of different factors that aid market growth. Some of the Major Companies covered in this Research…

Contract Plasma Coating Service Market Players Leveraging on Growth Opportunitie …

The Most recent study offered by "Stratagem Market Insights" focuses on Contract Plasma Coating Service Market size, share, growth rate, and market trends, as well as the parameters and factors influencing it in both the long term and short term. The report investigates the market trends in order to assess its current and future potential. Our Market analysis also provides market participants and new entrants with a comprehensive view of…

Cold Plasma Market Size, Share - Global Industry Forecast 2032 | Relyon Plasma G …

The market research report offers an in-depth analysis of the Cold Plasma market, helping players to prepare for the increasing hurdles ahead and ensure continued business expansion. With impeccable analysis, exhaustive research, and accurate forecasting, we provide a clear and authoritative study of the global Cold Plasma market, backed by data and figures that have undergone a rigorous verification process. This research is an exhaustive, comprehensive and carefully curated source…