Press release

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to be achieved at the end of the year.

The project LIFE+ GREENZO started last June and since then a complete study on the state-of-the-art that allow knowing in detail the zamak transformation industry productive process as well as the characteristics and management ways of the different generated waste has been made. Additionally, all the supply sources of Zinc Oxide in the industry and the different industrial processes that usually are made for the production of this oxide have been identified. Furthermore, the requirements of the zinc oxide to be obtained and applied in the rubber/EVA vulcanisation sector, as well as in the chemical catalysis in the reforming of bio-ethanol, have been identified.

As the basic objective of this project is to achieve the material valorisation of most waste from this sector, once the waste with greater potential and interest have been selected, it is necessary to define the requirements the pilot plant must met.

In this phase, the 4 waste categories selected in previous phases (slag, vibration sludge, chips, defective parts) have been tested with different technologies to verify their behaviour.

Slag, chips and defective parts have been tested in different ways of obtaining the voltaic arc (TIG, plasma…) in order to obtain Zinc Oxide.

Concerning the vibration sludge, different pre-treating tests have been carried out. These tests are mainly based on the removal of the organic material that it contains and to obtain the metallic fraction. Currently, great work is still being done in order to optimise the pre-treatment conditions that allow for the standardisation of its later treatment using the same technology than for the rest of selected waste.

With all these tests, the fist conceptual diagram of the future pilot plant has been made.

Enrique Añó, co-responsible technician in AIJU, says “the pilot plant will allow the valorisation of a big amount of waste from the zamak injection process” and Rubén Beneito adds “This pilot plant will allow for obtaining first-quality ZnO from a valorisation process, what constitute a milestone of industrial weight”.

This project will be developed in 3 years, and it is funded by the European Commission through the financing instrument LIFE13 ENV/ES/000173 GREENZO. It is coordinated by AIJU and the research centre ITQ-CSIC; moreover, the companies WORTEUROPE and CAUCHOS KAREY participate in this project. The project website was posted in September 2014 and its English version towards the end of October. You can visit it at www.lifegreenzo.eu.

AIJU is a non-profit making technological center funded in 1985 with the aim to boost the children’s products and leisure industries, and their connected and related industries through technological innovation transfer. With this aim, it has a multi-disciplinary staff of 75 professionals that develop their tasks in the diverse areas of which AIJU is composed and has the necessary infrastructure to manage the diverse tasks for which they are well-known.

In this project participates the Innovation and Sustainability department, specifically the Environmental and Energy areas, both with contrasted capacity and experience to ensure the consecution of the objectives of the project.

The main working lines of the Environmental area are the implementation of clean technologies (assessment of the feasibility of the pilot plant for the valorisation of waste, the development of environmental technological solutions, etc.); the sector adaptation to the emerging environmental legislation (adaptation of the children’s products sector to the new European Directives on waste, minimisation, energetic valorisation and the des-cataloging of dangerous waste, etc.) and the LCA and products eco-design.

On the other side, the Energy area has as objectives the R+D+I of new devices for the generation and storing of energy, the development of new fully-controlled and automated processes for obtaining “clean fuels”, or the development of supports or last generation catalysers that increase the energetic efficiency of the processes, among others.

For further information, visit: www.aiju.info.

AIJU

Avda. de la industria, 23

03440 Ibi

Tel. +34965554475

e-mail: proyectos@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The design of the pilot plant for the valorisation of zamak waste starts here

News-ID: 309803 • Views: …

More Releases from AIJU

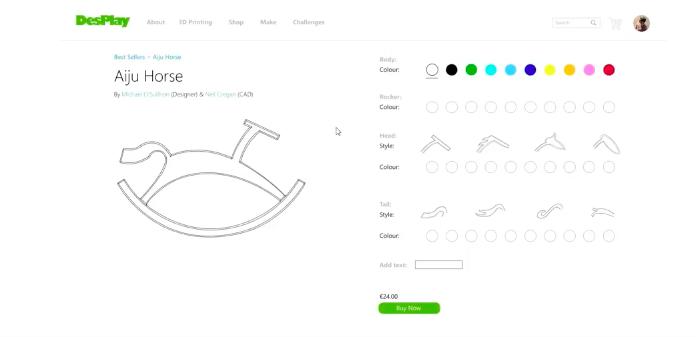

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for TIG

TIG Welding Machines (TIG Welder) Market Size, Outlook 2031 by Key Companies- Pa …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲: According to Verified Market Reports analysis, the global TIG Welding Machines (TIG Welder) Market size was valued at USD 1.2 Billion in 2023 and is projected to reach USD 2.5 Billion by 2030, growing at a CAGR of 8.5% during the forecasted period 2024 to 2031.

What is the current outlook for the TIG Welding Machines (TIG Welder) Market, and what factors are driving its growth?

The TIG Welding Machines market…

Global TIG Welding Power Supply Market Research Report 2023-2029

Global TIG Welding Power Supply Market: Driven factors and Restrictions factors

The research report encompasses a comprehensive analysis of the factors that affect the growth of the market. It includes an evaluation of trends, restraints, and drivers that influence the market positively or negatively. The report also outlines the potential impact of different segments and applications on the market in the future. The information presented is based on historical milestones and…

Global Micro TIG Welders Market Research Report 2023

Global Micro TIG Welders Market

Micro TIG welders are also known as Pulse-arc welders. Pulse-Arc welding or micro TIG welding uses electrical energy to create a plasma discharge. The high-temperature plasma, in turn, melts metal in a small spot. This process takes place in milliseconds. The process is clean and very controllable - perfect for intricate and minute welding applications on precious and non-precious metals.

The global Micro TIG…

TIG Torch Market is set to record exponential growth by 2031

TIG Torch Market Study Provides Latest Intelligence on Growth in 2021 and Beyond

Global TIG Torch supply-demand continues to be impacted by broader developments in the chemicals sector. The new TIG Torch market research report outlines the key factors that will impact production, supply, and demand during the assessment period (2021-2031).

The study tracks TIG Torch demand and sales in over 20 countries, highlighting the variance and unique set of conditions that…

TIG Torch Market Foraying into Emerging Economies 2031

TIG Torch Market: Overview and Dynamics

TIG Torch is the welding equipment that joins the primary and secondary metal by supplying the heat from it. This process is done by using shielding gas with or without adding any filler metal. Shielding gas is used typically for the protection of electrodes from contamination.

Further, TIG Torches creates clean welds because the heat input is controlled by foot pedal. Most of the developed regions…

TIG/m Winner of Multiple International Light Rail Awards

California tram company, TIG/m, LLC wins “Manufacturer of the Year”, “Environmental and Sustainability Initiative”, and “Highly Commended” in the Category of "Customer Initiative” at the Global Light Rail Awards 2020.

TIG/m, LLC is an innovative design, engineering and manufacturing firm supplying self-powered trams, tramway infrastructure, and tram system services to projects in various parts of the world including North America, South America, and Asia. Their mission to reduce the environmental impacts…