Press release

Increase children’s creativity by web-based customization possibilities and 3D printing

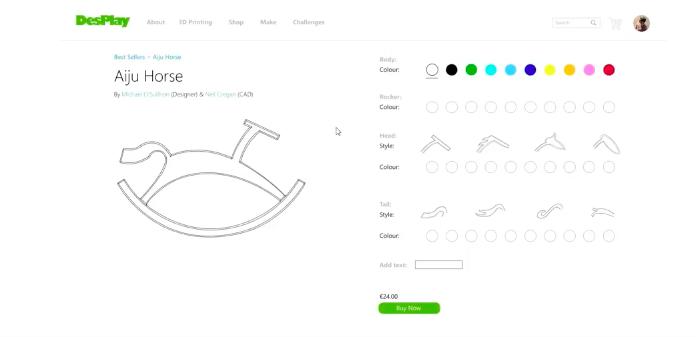

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.First technical developments allowing a web-based customization to generate the digital data needed for the manufacturing of custom-driven custom toys have been already achieved and are shown in the iBUS Product Purchase Journey video. These developments were made within the H2020 iBUS project. The main aim was to create a virtual environment that is easy to use due to intuitive user interfaces. Just with the shown possible customization options there result 256 different versions of the given ride-on toy.

These customised toys would be manufactured by 3D printing technologies. These, as innovative manufacturing technologies come up with unknown flexibility that enables the economical production of individualized products and components. The development of related business models as well as technical solutions for the toy industry as a branch with a high demand of customization is focused in the iBUS European H2020 project since September 2015. That those activities hit exactly today’s trends in the economical and technical sphere has been emphasized by Jon Cobb, executive vice president of corporate affairs at Stratasys as the manufacturer of most widespread 3D printing machines told Business Insider:

"I think children have a creative need to try to do something different so I think 3D printing with the capability of scanning or taking input from digital data makes it relatively simple to do customization of the product.”

The most challenging aspect considered in the iBUS European Project is toy safety when thinking about customized toys. Minor customizations in terms of changing the colour, adding stickers or names on a toy do not affect safety aspects. The last option shown in the figure below changes the structural properties of a component and therefore of the whole toy. Considering those effects regarding safety issues goes beyond a minor customization and will be implemented in further software modules and iterations. To meet the European safety requirements defined in the EN71 for customized toys will be the unique feature of the envisaged iBUS platform bringing together all stakeholders: Customers, designers, safety engineers, service providers for rapid manufacturing solutions and logistics.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 646167.

Awaken Interest? Please visit @h2020ibus

The project is Lead by UL (University of Limerick) and participated by 10 additional partners.

AIJU

Avda. de la Industria, 23

03440 Ibi (Alicante)

Tel. +34 965554475

e-mail: ibus@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Increase children’s creativity by web-based customization possibilities and 3D printing here

News-ID: 701490 • Views: …

More Releases from AIJU

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Image

Nano Banana Introduces Advanced AI Image Generation Technology Transforming Text …

Introduction

Artificial intelligence has transformed the way visual content is created, edited, and consumed. From marketing campaigns to personal creative projects, AI-powered image generation tools are enabling users to produce high-quality visuals with minimal effort. Among these innovations, advanced text-based image generation models stand out for their ability to understand natural language and translate ideas into compelling visuals.

This article explores how a next-generation AI image generation model is reshaping creative workflows,…

Image Consulting Market Outlook, Trend Analysis, Current Growth, Future Scope An …

The latest report published by Coherent Market Insights highlights the growth prospects of the Image Consulting Market from 2025 to 2032. In-depth research on Industry Size, Share, Business Analysis, Growth Factors, and Regional Forecast. The market report gives a purposeful depiction of the area by the practice for research, amalgamation, market size, overview, and review of data taken from various sources. The market study includes information on market factors such…

Image Consulting Market: Opportunities in Executive Coaching, Wardrobe and Style …

Description

Coherent Market insights announces the release of the report "Image Consulting Market - Demand, Growth, Opportunities and Analysis of Top Key Player Forecast to 2030", The Image Consulting market research report provides a comprehensive analysis of the current state and future potential of the Image Consulting market. The report covers various aspects, including market size, growth trends, key players, market segmentation, competitive landscape, industry drivers, and challenges. The objective of…

CMOS and sCMOS Image Sensors CMOS and sCMOS Image Sensors

The latest CMOS and sCMOS Image Sensors market study offers an all-inclusive analysis of the major strategies, corporate models, and market shares of the most noticeable players in this market. The study offers a thorough analysis of the key persuading factors, market figures in terms of revenues, segmental data, regional data, and country-wise data.

Request a sample on this latest research report @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5096977

Top Key Players are covered in this report:…

Interventional Image-Guided Systems Market Report 2018: Segmentation by Product …

Global Interventional Image-Guided Systems market research report provides company profile for St. Jude Medical, Neusoft, Konica Minolta, Samsung Medison, Shimadzu, BenQ Medical Technology, Asahi Roentgen, GE Healthcare, Olympus, Philips Healthcare, Siemens Healthineers, Toshiba Medical Systems and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth…

Image Sensors Market By Types - CCD Image Sensors, Linear Image Sensors, CMOS Im …

The vendor landscape of the U.S. image sensors market includes companies such as Dalsa Corporation, Omnivision Technologies Inc., Micron Technology Inc., and Sharp Microelectronics of the Americas. The market players are witnessing an increased demand for linear image sensors owing to the extensive applications of CMOS (complementary metal-oxide semiconductor) image sensors across a wide range of applications. In fact, the majority of the revenue of these market players comes from…