Press release

AIJU contributes to the environment with a new plastic material reinforced with natural fibre.

AIJU has developed a new plastic compound made with natural dry biomass, specifically the almond shell, for industrial purposes. The result is a compound material with a wooden appearance and new properties which have been analyzed in-depth.This new material provides other eco-efficient alternatives which reduce the plastic content, derived from non-renewable sources, and at the time give value to this natural waste which is produced in great quantities in Mediterranean countries, and whose only other use is for incineration purposes.

A complete characterization of this material has been done in the study with distinct quantities of almond shell powder, determining the influence of this content on the physical, mechanical, thermal and rheological properties of these formulations.

“The almond shell is a natural waste which is valid for reinforcing common plastic materials. A material with a wood-like appearance is obtained and in general the material has better properties than the non-reinforced plastic material,” explains Suny Martínez responsible for the Material Area at AIJU. “The tensile, bending, hardness, density and temperature resistances increase in reference to polyethylene without the additive. The viscosity at non-elevated temperatures increases as well.”

The obtained formulations can be transformed by injection processes in a similar way to non-compound materials, although the pellets must go through a drying process to eliminate the absorbed moisture in the shell before the transformation, and the temperature must not exceed 220ºC in the process to avoid the almond shell decomposition.

In parallel, AUJU is developing a new material with almond shell for transformation in Rapid Manufacturing processes. Test specimens, in a halter shape, have been successfully sinterized for their characterization, and the enhancement of the recycling characteristics are being worked on as they lose properties and must be rejected after several uses in the process without being sinterized.

These tasks have been carried out within the frame of the IBE-RM Project, partially funded by MICINN and the EU with FEDER resources (Expedient PSE-020000-2009-001) and MatSinter funded by IMPIVA (Expedients IMIDIC/2009/80 y IMIDIC/2010/45). Additionally, we would like to thank the Cooperative “la Trencaora” from Castalla for providing the almond shell.

AIJU

The Toy Research Institute (AIJU) is a non-profit making organisation, located in Ibi, the geographic centre for the manufacture of toys in Spain. It was founded in 1985 with the collaboration of the Spanish Toy Manufacturers Association (AEFJ) and the Regional Government (IMPIVA).

Its aim is to transfer and allow toy manufacturers access to knowledge and information regarding new technologies in order to improve their competitivity, while offering technological and financial assessment and supporting the professional development of people involved in the sector. For this purpose, it has a staff of 75 professionals which develop their work in the different areas which make up AIJU.

The department where these tasks will be carried out is that of Product Development – Laboratory Department, specifically the Processing and Materials area. This department is closely linked to the Rapid Prototyping Area, which has been working on the research of SLS Equipment for 10 years now, studying its feasibility for use in the manufacturing of functional prototypes and mould prototypes with the objective of reaching sets of final materials.

AIJU is an active member of the Rapid Manufacturing European Platform and the Spanish Mirror led by ASERM, the Spanish Rapid Manufacturing Association. It is also a member of EuMAT and Manufuture. AIJU is the coordinator of the working group, “Rapid Prototyping Proposal SP3 (materials) Lab,” and a member of the “Materials” group promoted by REDIT among the RDT Centres of IMPIVA’s Network.

In the field of standardisation, the entity is working on the potential feasibility of proposed rules as well as new safety criteria for toys, with participation in several proficiency testing schemes both on a National and European Level. Thus, it is participating in the development of new standards for toys in the European Committee of Normalization (CEN).

AIJU

Avda. de la Industria, 23

03440 Ibi (Alicante)

proyectos@aiju.info

http://www.aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AIJU contributes to the environment with a new plastic material reinforced with natural fibre. here

News-ID: 155198 • Views: …

More Releases from AIJU

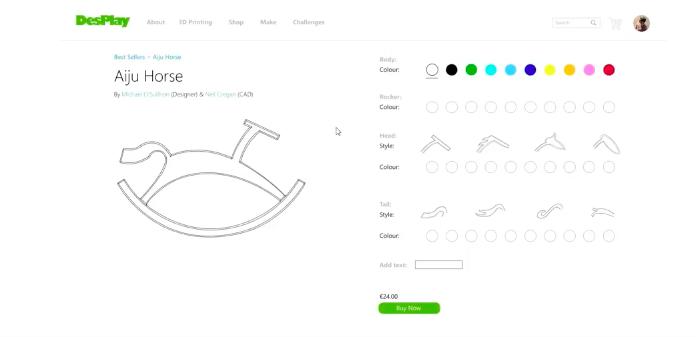

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Rapid

UYEE Rapid Tooling Announces Expert CNC Machining and Rapid Prototyping Services

UYEE Rapid Tooling Co., Ltd, a trusted provider since 2005, announces its advanced capabilities in high-speed CNC machining, rapid prototyping, and low volume manufacturing solutions.

UYEE Rapid Tooling Co., Ltd, a dedicated leader in manufacturing services since 2005, today highlighted its comprehensive suite of services designed to meet the demanding needs of modern product development and production. With a strong commitment to customer success, UYEE specializes in delivering high-speed CNC machining,…

Rapid Infuser Market - Swift Restoration, Enhanced Recovery: Rapid Infuser Optim …

Newark, New Castle, USA: The "Rapid Infuser Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors.

Rapid Infuser Market: https://www.growthplusreports.com/report/rapid-infuser-market/8896

This latest report researches the industry structure, sales, revenue,…

Rapid Infuser Market - From Emergency to Efficiency: Advancing Patient Outcomes …

Newark, New Castle, USA - new report, titled Rapid Infuser Market The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Rapid Infuser market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their impact on the global Rapid Infuser market. The report offers an overview of the market, which…

Rapid Pregnancy Tests Market: Size & Trends Shows a Rapid Growth by 2027

The pregnancy test kit confirms pregnancy by detecting the level of human chorionic gonadotropin (HCG) in the urine. The growing demand for an easy and convenient way to get faster results, and the easy availability of pregnancy kits through various distribution channels, including pharmacies/pharmacies, online stores, etc., is increasing the demand for pregnancy test kits.

(Get 15% Discount on Buying this Report)

A full report of Global Rapid Pregnancy Tests Market is…

Rapid Machining Launches New Service

Rapid Machining, one of the largest prototype machining manufacturers in the United States, is excited to announce a new standard 5 day lead time service for lathe parts. Responding to customer demand, Rapid Machining purchased new equipment and reconfigured the manufacturing floor to make this lead-time reduction possible from a standard 7 day lead time. The new service is currently available for lathe parts with a variety of materials and…

RAPID: Lockheed Martin Approved

Nashua, NH – April 4, 2016 – RAPID was announced as an approved vendor for Lockheed Martin as of April 2016. RAPID has been working with Lockheed Martin divisions for a number of years, but the addition to the Approved Vendor list will strengthen and build upon the existing relationship.

Lockheed Martin is an aerospace, defense, security, and advanced technology company that employs over 116,000 professionals worldwide. Lockheed Martin has…