Press release

Process Monitoring of Vibrations at Hydro Turbines

Delphin TopMessage System Diagnoses FaultsCHESTERLAND, OH—March 16, 2016

Delphin Technology recently provided the vibration monitoring solution for Femaris, a Romanian company focusing mainly on providing products and services for measuring and analyzing technical parameters.

Femaris offers complete solutions for the implementation of predictive and proactive machine maintenance, as well as online and offline monitoring of industrial values. This includes static and dynamic balancing of different kinds of rotors, data acquisition systems to record vibrations and noises, and service including training of personnel. CAS DataLoggers, a Delphin distributor, presents this Applications Note showing how Femaris supplied its own customer with a Delphin system to monitor vibrations in hydro turbines.

Introduction:

Femaris required a solution for its customer HIDROELECTRICA SA, Romania’s main electrical producer. The company is divided in several branches depending on the geographic area. HIDROELECTRICA has an installed power of 6438 MW and produces approximately 30% of the entire electrical power in Romania. This particular Delphin Vibration Monitoring system was implemented in Hidroelectrica Oradea SA.

Application/Problem:

Technicians at Hidroelectrica noticed a suspect sound originating from the generator of a turbine, a sound believed to be caused by vibrations at a hydro turbine within their plant. Because of this situation they required vibration measurement. To discover the source of this sound, their main objective was to install an easily-configurable real-time portable monitoring system to increase the safety conditions and improve fault prediction.

Besides this, the system had to be modular so that it could be extended in the future, for example to make absolute vibration measurements with piezoelectric accelerometers.

The customer decided to install a Delphin TopMessage Data Acquisition and Control system along with Delphin ProfiSignal software to monitor the following parameters:

- Global vibration – peak-to-peak displacement

- FFT analysis

- Smax parameter

- Orbit

- Trend analysis etc.

Technical Conditions:

ISO 7919-5:2005 Mechanical vibration, Evaluation of machine vibration by measurements on rotating shafts. Part 5: Machine sets in hydraulic power generating and pumping plants

ISO 10817 Rotating shaft vibration measuring system

Measurement direction: Radial on two directions X – Y with two proximity transducers mounted at 90°

Measured parameters: Relative vibration of journal bearing

Measuring unit: Peak-to-peak displacement of vibration [µm] for the distance between the sensor and shaft

Analysed machine: Hydro turbine Vertical Kaplan, 10 MW power.

Monitored journal bearings: Turbine bearing - LT

Inferior radial bearing - LRI

Axial radial bearing – Lrax

Solution/Hardware:

For this application Femaris recommended the following components:

- Delphin TopMessage Master device

- AMDT Module (enables shaft/bearing vibration monitoring & analysis)

- Voltage divisor

- Proximity systems – Transducers with conditioner

- Delphin ProfiSignal Basic software

Here the necessary vibration measurements were performed with proximity systems mounted on all three journal bearings of the turbine. Two transducers were mounted on each journal bearing, with a radial direction and at an angle of 90° between them.

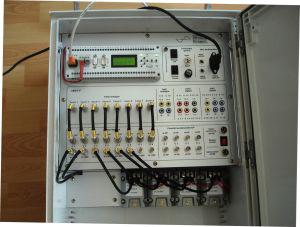

The TopMessage system was mounted within an portable electric panel. The customer requested that the system must be portable to be mounted on different hydro turbines that presented electrical or mechanical faults.

The software used for fault diagnostics are ProfiSignal Basic and ProfiSignal Vibro.

Following the vibration measurements, it was established that the operating mark is UNALLOWED according to ISO 7919. The vibration diagnosis indicated a misalignment of the turbine’s shaft, but this offsetting is caused by the instability of the inferior radial bearing LRI, practically an increased mechanical looseness inside this bearing having the Y direction.

The software tracks the relative vibrations at different turbine loads.

Proposal/Hardware:

Following this vibration diagnosis, the data recommended that users check the fixation mode of bearing LRI onto the foundation, the state of the bushing, and also the mechanical looseness inside the bearing.

While checking bearing LRI, the repair team found that the nuts which adjusted the looseness in the bushing (Y direction) were all destroyed, as well as the thread on the bolts.

The absolute vibration measurements were taken with accelerometers using a portable analyzer, and the highest vibrations were recorded on the radial axial bearing LRAx, while on the inferior radial bearing the vibrations amplitudes were small.

In conclusion we can say that the machine diagnosis of those machines which have journal bearings in their assembly are done more precisely if the vibration measurements are done with proximity transducers and are acquired using the on-line mode, simultaneously on all the machine’s bearings. For this purpose the TopMessage system was ideal here and the customer was very satisfied post-installation.

Benefit Summary:

The advantages of vibration monitoring using the Delphin TopMessage system and the Profisignal software are as follows:

- Simultaneous monitoring of vibration amplitudes on all the bearings of the machine

- The possibility of extending the system for on-line monitoring and other technical parameters needed for machine diagnosis

- The creation of virtual channels to calculate looseness in the journal bearings

- The possibility of copying the measured data – amplitude 1x and phase 1x – in a balancing program which allows balancing--in situ, static and dynamic--of the rotors.

- Precession movement simulation of the shaft within the journal bearings.

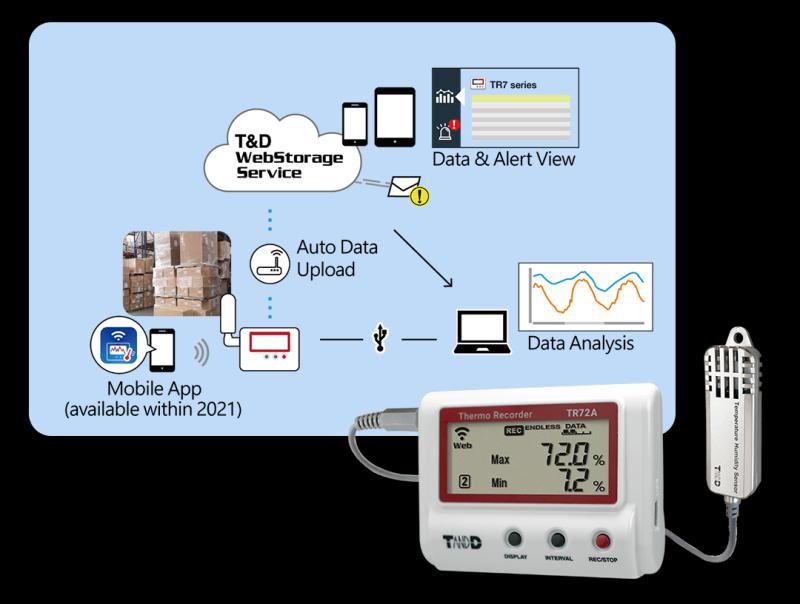

- Data transmission and storage within the TopMessage device and on the hard disk of a computer.

- The ability to connect vibration transducers with an output of 4-20 mA as an economical solution for vibration monitoring

- The increase in safety conditions and the prevention of machine damage with the help of the Alarm Management software and the TopMessage system’s analog and digital outputs.

To learn more about Delphin Data Acquisition and Control systems, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or visit our website at www.DataLoggerInc.com.

Contact Information:

CAS DataLoggers, Inc.

8437 Mayfield Rd.

Chesterland, Ohio 44026

(440) 729-2570

(800) 956-4437

sales@dataloggerinc.com

www.dataloggerinc.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Process Monitoring of Vibrations at Hydro Turbines here

News-ID: 326376 • Views: …

More Releases from CAS DataLoggers

New XH10 & XH11: Data Loggers Enhance Long-Distance Transport

CAS DataLoggers is pleased to announce the XHLogger series from Brainchild Electronics Co., Ltd. The new XH10 and XH11 temperature and humidity data loggers are designed specifically for environmental monitoring during cargo transportation. These reusable devices connect to a computer via USB and automatically generate a PDF report of the recorded data, or they can be used in conjunction with the Data Logger Viewer (DLV) software for in-depth data analysis.…

New MSR Data Loggers from MSR Electronics GmbH

CAS DataLoggers is pleased to announce that we have partnered with Swiss company MSR Electronics GmbH to bring the MSR family of universal data loggers to our customers. Designed to meet the highest standards of precision and reliability, the new MSR data loggers are compact with large memory to handle various measurement tasks such as measuring and recording shocks, vibration, temperature, humidity, pressure, or light.

Why Choose MSR Data Loggers?

The ability…

Ensuring Workplace Safety: Data Loggers for Compliance With California Regulatio …

In workplaces across California, ensuring the health and safety of employees is paramount. This commitment is not just a moral imperative, but a legal requirement under California Code of Regulations Section 3395, which mandates specific measures to ensure workplace safety by protecting workers from heat illness. Among these measures is the monitoring of environmental conditions such as temperature and relative humidity, critical factors that can significantly impact employee well-being.

Understanding California…

New AirGate 4G Cellular Router from Novus

NOVUS presents AirGate 4G, an industrial VPN router for cellular networks. Data sending is secure with this new device as it uses encryption protocols and firewall systems most commonly used in IT infrastructures, including automatic fallback for 4G, 3G, and 2G cellular networks. AirGate 4G is CE Mark certified and was developed for industrial environments. It can maintain its high availability performance even in extended operation situations, being equipment suitable…

More Releases for Delphin

Delphin Releases New ProfiSignal Web Software

Web-Based Software for Measurement & Testing

CAS Dataloggers is pleased to announce the release on the new ProfiSignal Web Software package from Delphin Technology. ProfiSignal Web is state-of-the-art application for measurement and monitoring that allows decentralized data acquisition, centralized data storage and browser-based monitoring using a PC or mobile device. Accessing and analyzing measurement data from Industrial, Environmental or Life Science applications has become more flexible than ever before. Whether for…

Connect Your Process to the Cloud with Delphin

Streamline Your Process or Test Stand

Around the world, many companies are benefiting from the new opportunities and possibilities of the Internet of Things (IoT). Increasingly in factories and plants, specialists from different departments work together in teams to optimize processes and to test new products.

Linking to the cloud is fast becoming an integral part of condition monitoring, process optimization, or simply to achieve more effective system communications.

These new…

Delphin Offers Extensive Driver Development

Let Delphin Develop Your Application!

For flexible use in many different measurement applications, communication between Delphin data loggers and third-party ICA technology is possible using standard protocols. The communication interfaces in Delphin ProfiSignal software and hardware provide a multitude of options for exchanging data. CAS DataLoggers distributes Delphin dataloggers in the US--just contact us at 1-800-956-4437 if you have questions about connecting an ICA system to Delphin hardware or software.

…

Delphin Upgrades ProfiSignal Measurement Software

Version 4.2.10 Available for Download at CAS DataLoggers

CAS DataLoggers and Delphin Technology are proud to announce the release of an improved version of Delphin’s popular ProfiSignal data acquisition software. Version 4.2.10 adds new bug fixes as suggested by users around the world. You can download the new version from our Delphin Downloads page at http://www.dataloggerinc.com/downloads/delphin.php. Whether you work in test, process control or another application, at CAS DataLoggers we can…

Precision Electrical Measurement Using Delphin

Fully-Automated Engine Test Stands

Motor Test stands are required during the automotive R&D phase for serial testing and also for endurance trials. Measurements taken during the developmental phase such as Temperature and Voltage are fully-automated whenever possible. Sensors check the electrical and mechanical properties of the test sample as well as temperature patterns and overload operation. Testing conditions can vary widely--from the tiniest of motors to large drives in the megawatt…

Delphin Systems Provide SDI-12 Sensor Integration

Versatile Data Logger Connects to Enviro Smart Sensors

The SDI-12 interface (Serial Data Interface at 1200 Baud) enables, via a digital signal, the establishment of a connection with multiple "low-power" sensors and a data logger. Sensors can be operated on the bus with asynchronous, serial communication protocols. Such sensors (e.g. for soil moisture, soil temperature, air humidity, water potential, electrical conductivity, etc.) are primarily used in environmental engineering.

Now users can…