Press release

AIJU develops the project "INNOVARISK" on determination of risks in innovative children’s products

The methodology developed will facilitate risk assessment of innovative children products whose hazards are not covered by current safety standards.The performance of this R&D project "Hazard characterization in innovative children’s products. Development of methodologies for risk management. -INNOVARISK-", has allowed to develop a methodology for a specific integral risk management, by types of product for the main lines of innovation present in the current market of children's products.

With this purpose, and as a starting point, a market survey was conducted in order to know the main lines of innovation in children. This study includes more than 150 types of products, the new technologies (such as "multi-touch") being a source of innovation present in a large proportion of the products identified, as in the case of tablets for children. For these products, the results of the project have shown that the "multi-touch" technology can entail some hazards, like the overload of the visual and auditory sensory systems, not covered by current regulations, whose risks must be treated and minimized to ensure high protection of the health and safety of particularly vulnerable consumers, such as children.

In this sense, the methodology developed in the project INNOVARISK is a tool for dealing with the risks of innovative product not covered by current regulations, in order to remove or minimize them considering the balance between the optimal safety level and innovation.

The project has focused on innovative children’s products lines, especially relevant in the Valencian industrial sector, such as toys, child care articles and playground equipment, among others.

Project funded by the Institute for Small and Medium Industry of the Generalitat Valenciana (IMPIVA) within the "Strategic Development Plan". This project is co-financed by the ERDF, within the ERDF Operational Programme of Valencia 2007-2013.

ABOUT AIJU:

The Toy Research Institute (AIJU) was established in June 1985. Located in Ibi, in Alicante, AIJU is a non-profit association focused on researching, developing and improving the quality and safety of children’s products. Accredited for toys since 1989, the laboratory is currently increasing its accreditations; being the first laboratory accredited by ENAC for the testing of toys, childcare products, playgrounds, play equipment and playground surfacing and materials in contact with food. Besides, AIJU is an Inspection Institution accredited by ENAC for playgrounds.

AIJU a member of several forums and committees of national and international standardisation related to child safety. It is also an EU Notified Body that is authorised to issue EC-type certificates according the Toy Safety Directive.

The centre has well-equipped premises and brings together a multidisciplinary team of 80 technicians, who advise and help companies, doing so from the different departments within AIJU: Product Engineering and Laboratory (child safety, materials, processes, prototype, etc...) Management and Innovation Systems, Educational Research – Product, Training, Information and Management.

One of the main objectives of AIJU is to help the children’s products industry to improve its competitiveness, advising on educational and developmental aspects of children and new needs and social situations related to them, their welfare and the products intended for use by them.

AIJU is the only European centre specialised in all aspects of children’s products, from research of raw materials, product design or safety assessment to pedagogy and child development studies in relation to children's products.

Find further information at: www.aiju.info.

M. Cruz Arenas

Childcare Managing Director

AIJU

Avda. de la Industria, 23

03440 Ibi

Tel. 965554475

puericultura@aiju.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AIJU develops the project "INNOVARISK" on determination of risks in innovative children’s products here

News-ID: 246987 • Views: …

More Releases from AIJU

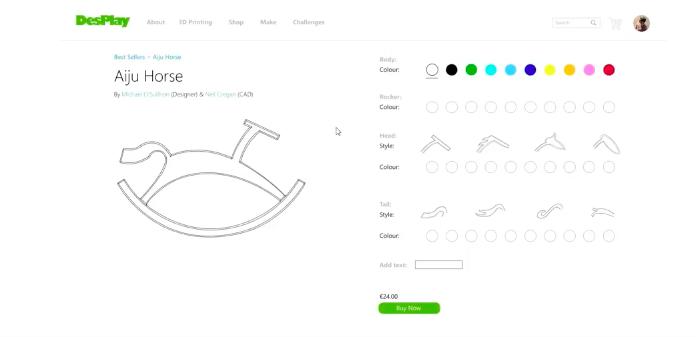

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…