Press release

SASAM project starts – Support Action for Standardization on Additive Manufacturing

This project will contribute to set the Standards for Rapid prototyping and Additive Manufacturing within European IndustryInternational and European Standards regarding Additive Manufacturing (AM) are urgently required to promote and help implement a widespread use of the AM process and to evaluate existing products. The lack of availability of International and European Standards is hampering real industrial implementation of AM technology. As a consequence, SASAM’s project, whose kick-off meeting was held on September 17th & 18th 2012, aims at covering this gap.

This project has the objective to integrate the opinion of all stakeholders within Additive Manufacturing to establish a Roadmap to implement the necessary basis to reach the effective standardization of AM technologies. The European Standards Organization CEN has will actively support this project by organizing two open events where stakeholders will meet to discuss AM standardization needs. The first event is planned for March 2013.

The SASAM project is very important, as the rapid evolution of Rapid Prototyping and Additive Manufacturing has overtaken the standardization work and their protocols. Accordingly, no objective comparable information is available for any products manufactured either by Additive Manufacturing or Rapid Prototyping. As a result, industry finds itself in an unclear environment and must rely on the information given by providers, which could provoke considerable conflicts of interest. Additionally, its relationship with other over-regulated industries that use conventional processes makes it difficult for Additive Manufacturing to comply with and enter into fair competence with these conventional manufacturing techniques.

This project, lead by TNO, is supported by the European Commission within a NMP-SA-2012-319167 (G.A II.30.4). It is structured in 5 Work Packages (WP) and foreseen to be developed within 18 months, from September, 1st, 2012. It is lead by TNO and participated by 18 partners of the size of Siemens, SINTEF or CETIM, several research organisations like SIRRIS (B), University of Loughborough (GB), or inspire (CH), and several national standardization organisms from The Netherlands (NEN), France (UNM) and Sweden (SIS).

AIJU Research Centre is a Spanish private, non-profit making organization aiming to boost research, development and technological innovation in consumer and children products, leisure and plastic and related industries (mould makers, packaging, automotive, electronics,...). It is located in Ibi (Alicante) and its capabilities and technologies have been constantly evolving since it was founded, back in 1985, in order to adapt to new industry requirements (with more than 500 associated companies and 1000 clients) and trends. With 78 employees and premises of 5000 m2, including testing laboratories, Play Lab, pilot plants and training rooms, AIJU has a multidisciplinary staff composed by designers, chemists, engineers, psychologists and expert technicians in diverse fields of knowledge working in the development, testing and validating different products considering technical, industrial, environmental and sustainability, quality and safety requirements.

AIJU is a notified body in Europe (and accredited also in the USA) for safety assessment on different children products, playgrounds, etc., regarding chemical and mechanical risks, and is member of other four CEN Committees.

Some of the current Research fields and services of AIJU include Product development, Additive Manufacturing and Reverse Engineering (functional and aesthetic prototypes, rapid tooling, pre-series, digitalization, design of moulds, CAD/CAE, EDM electrodes etc.); Development of new materials and processing (new formulations, nanomaterials, injection moulding, energy…); Customization and comfort evaluation of products fitted to the body geometry; Simulation & Virtual Reality; Eco-desing; Research on play and disability, active ageing, accessibility, assistive technologies, sporting, etc., combined with ICT technologies.

AIJU

Avda. de la Industria, 23

03440 Ibi (Alicante)

Tel. +34965554475

Pepi Galvañ (proyectos@aiju.info)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release SASAM project starts – Support Action for Standardization on Additive Manufacturing here

News-ID: 245263 • Views: …

More Releases from AIJU

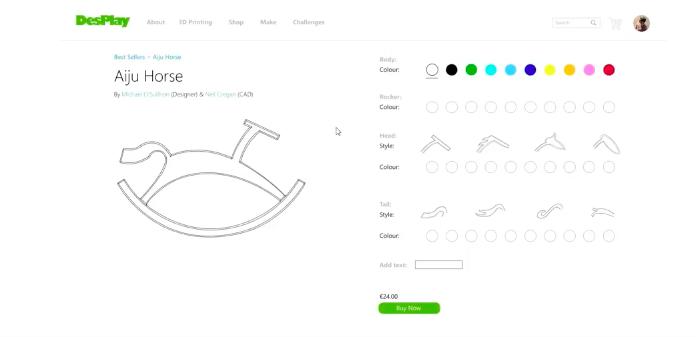

Increase children’s creativity by web-based customization possibilities and 3D …

3D printing technologies are being considered by some innovator leaders as a production method like any other, although some adjustments, innovations and improvements are still required. Additionally, it has been detected that fully functional business models that consider AM technology within its supply chains are not yet available. Therefore, the project iBUS was conceived for the supply of custom-driven customised toys.

First technical developments allowing a web-based customization to generate the…

European Consortium seeks to create new platform for design and supply of custom …

The EU funded Horizon 2020 iBUS project consortium is developing a new internet based business model, providing a platform for both, the design and the implementation of a sustainable local supply chain, of demand driven customised toys, meeting all product safety legislation within the EU.

Ibi, April 21th, 2016. iBUS (integrated business model for customer driven custom product supply chain) is developing a new business model, based on new developments in…

The design of the pilot plant for the valorisation of zamak waste starts

The beginning of GREENZO’s compacted pilot plant will allow for first-quality zinc oxide from by-products of the Zamak transformation industry.

To this day, LIFE+ GREENZO project is totally immersed in the design phase and technology testing of the pilot plant. It is expected to have the final design at the end of this month of May, when the physical development of the pre-industrial pilot plant will start, it is foreseen to…

New pilot plant for the obtention of zinc oxide from zamak waste

The implementation of this pilot plant at industrial scale will allow to valorise waste coming from the zamak transformation industry and currently managed by depositing it in safety landfills, thus reducing the costs charged to manufacturing companies for its management.

The new pilot plant will allow the valorisation of waste generated within the industrial processes of injection of zamak pieces for its application in products of great usability, like the manufacturing…

More Releases for Additive

Prominent Additive Manufacturing Market Trend for 2025: Development of Digital A …

Which drivers are expected to have the greatest impact on the over the additive manufacturing market's growth?

The additive manufacturing market is set to flourish due to the surging demands for 3D printing. This term refers to the process of making three-dimensional solid objects from electronic files. 3D printing brings cost-effectiveness and flexibility to additive manufacturing, specifically in manufacturing personalized components and planning before an operation. For example, AZoNetwork UK Ltd.,…

Metal Additive Manufacturing Systems Market to See Huge Growth by 2030 | Renisha …

Advance Market Analytics published a new research publication on "Metal Additive Manufacturing Systems Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Metal Additive Manufacturing Systems market was mainly driven by the increasing R&D spending across the world.

Get inside Scoop…

Additive Masterbatch Market Report 2024 - Additive Masterbatch Market Size, Shar …

"The Business Research Company recently released a comprehensive report on the Global Additive Masterbatch Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Medicated Bath Additive Market Report 2024 - Medicated Bath Additive Market Grow …

"The Business Research Company recently released a comprehensive report on the Global Medicated Bath Additive Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The medicated bath…

Laser Additive Manufacturing Market Is Booming Worldwide| GE Additive, Autodesk, …

Advance Market Analytics published a new research publication on "Laser Additive Manufacturing Market Insights, to 2028" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Laser Additive Manufacturing market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive PDF Sample…

Aquaculture Additive Market

The Insight Partners analysts forecasts the latest report on “Global Aquaculture Additive Market (Covid-19) Impact and Analysis by 2027”, according to report; The Aquaculture Additive Market report covers the overall and all-inclusive analysis of Market with all its factors that have an impact on market growth. This report is anchored on the thorough qualitative and quantitative assessment of the Aquaculture Additive Market.

The COVID-19 outbreak is currently going the world…