Press release

Review: VITRONIC at CeMAT exhibition 2011: Camera systems for data acquisition in Intralogistics

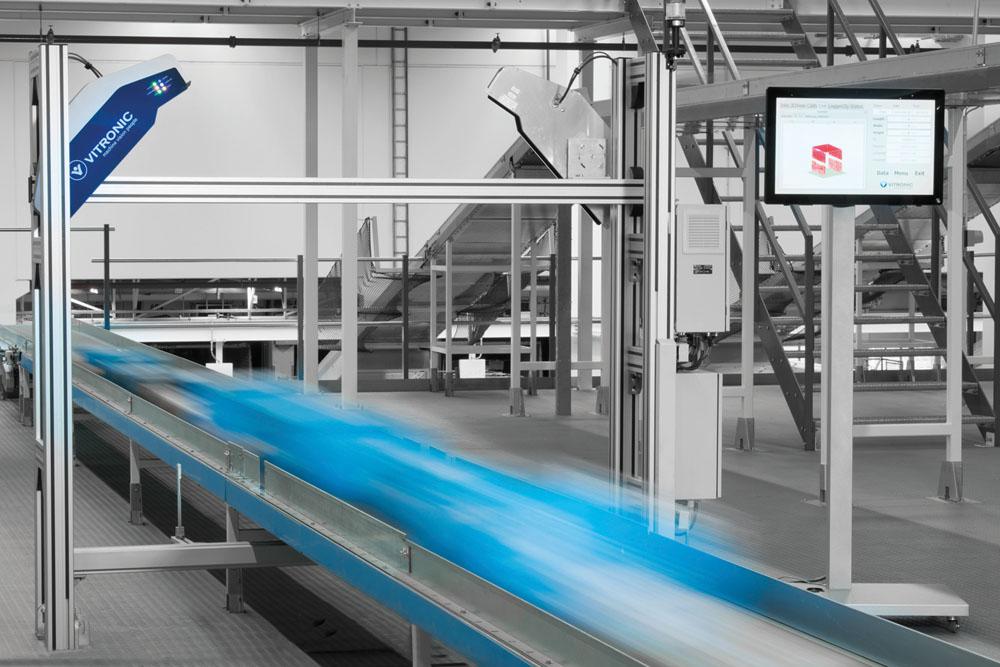

Wiesbaden, 12th May 2011 – VITRONIC presented camera-based Auto-ID systems at this year’s CeMAT in Hannover from 2nd to 6th May. These camera systems outmatch conventional laser scanners regarding the acquisition of customer- and object based data of goods in intralogistics.VIPAC systems for manual, semi-automatic and fully automatic data acquisition have been presented at the booth. These systems acquire data along the entire process chain in intralogistics, i.e. in incoming goods departments, during the registering of returns, in commissioning, sorting and outgoing goods.

The VITRONIC sales people outlined the quality of the technical discussions with the booth visitors. “Sometimes, less is more. The number of visitors compared to the last exhibition in 2008 has not increased, but we had more high-level discussions about precise projects”, said Klaus-Michael Bücher, Sales and Marketing Director at VITRONIC.

VIPAC camera systems for Intralogistics: More efficiency and productivity, less expenses. VITRONC Auto-ID sytems recognize, analyse and evaluate barcodes, 2-D codes and characters (OCR) - also many different code types in one image (multi-code reading). Furthermore, important additional information such as the volume and the weight of the package can be acquired and be incorporated into connected enterprise resource planning systems or CRM-solutions and trigger ongoing processes.

The advantage of camera systems compared to conventional technologies is not only the significant higher read rate. Employees no longer have to subsequently supplement illegible data manually. This saves time and money, i.e. for manual read stations and additional conveyor technology. Acquisition processes can be accelerated, throughput times reduced and the productivity can be increased. The collected information can be evaluated and be used for process optimization. The operating costs are lowered because cameras have very long useful lives and require extremely little maintenance.

Since its foundation in 1984, VITRONIC GmbH has continued to offer machine vision systems in four main areas: Logistics, Industrial Automation, Traffic Technology and Body Scanning. Now represented on five continents, the company offers standardized and turnkey solutions for a diverse range of machine vision applications.

A series of high-end technical products are designed, developed and manufactured in-house by a highly qualified and motivated team of over 340 employees. With its state-of-the-art products, VITRONIC is a leader in this rapidly developing market.

More than half of all VITRONIC products were developed in the last five years. This is only possible through constant innovation and the creation of new solutions, and supported through constant investment in research and development.

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

D – 65189 Wiesbaden

Tel: +49 (0)611 – 7152 - 0

Fax: +49 (0)611 – 7152 - 133

Birgit Löschner

Tel: +49 (0)611 – 7152 - 261

birgit.loeschner@vitronic.de

www.vitronic.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Review: VITRONIC at CeMAT exhibition 2011: Camera systems for data acquisition in Intralogistics here

News-ID: 174809 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for CeMAT

Lydia Voice Market to Witness Notable Growth by 2027 Covid-19 Analysis | CeMAT, …

This in-detail Lydia Voice market analysis presents a review on crucial industries, which are greatly helping to impel the market growth. This market study report further depicts mergers, acquisitions amid startups, strategies, product launchings and collaborations followed by industry players of the market. Industry players of the market take more efforts to go with new technology to get a competitive advantage over the cut-throat competition of the market. In order…

Wind of Change for Intralogistics - Bizerba at the CeMAT 2011 in Hannover (hall …

Balingen, 2nd May 2011 – Driven by globalisation companies are confronted with dynamic challenges. The goal is to constantly improve the logistical flows of material and goods that take place on the company grounds and to reduce the time required for the processing of orders. At the CeMAT 2011, one of the most important intralogistics fairs in the world, Bizerba is going to present from 2nd to 6th May system…

PSI Presents Innovative Logistics Solutions at the CeMAT

Berlin, 1 April 2011 – Under the motto of “Smart Grid for Logistics“,PSI subsidiary PSI Logistics GmbH will be presenting new software developments for the logistics sector at the CeMAT 2011 from 2 to 6 May in Hannover (Hall 27, Stand D18). Along with new modules and functionalities, new schools of thought for logistics as well as forums on the hot subjects of intra logistics will round out the company’s…

VITRONIC presents at this year’s CeMAT: Advantages of camera systems for data …

Highest Read Rates for Maximum Throughput

Wiesbaden, March 23rd 2011 – In intralogistics, customer-related and object-related data of goods is acquired and processed at different locations. Currently, laser scanners and camera systems are used for this purpose. However, the future belongs to the camera technology that provides significant advantages: it increases the degree of automation, accelerates processes, improves the efficiency and productivity with respect to personnel placement and reduces the logistics…

Schaltbau GmbH at the CeMAT in Hanover

Munich, 18/02/2011: At the CeMAT in Hanover (2nd – 6th May 2011) Schaltbau GmbH presents charging connectors, combination contactors and emergency cut-off switches. These products are used first and foremost in forklift trucks. The main exhibits are the charging connectors. The LV Series is modular, thus permitting scalable solutions between vehicle, battery and charger. The LV500 charging connector assures permanent operating currents of up to 500 Amperes, and has been…

CeMAT 2008 Trade Fair in Hannover, Germany: AMI Highlights Customized Conveying …

Conveying technology and material handling systems for a wide range of applications will be showcased by AMI Förder- und Lagertechnik GmbH at this year’s CeMAT trade fair in Hannover, Germany. From May 27 to 31 visitors of the 100 m² Stand H 44 in Hall 27 will gain insights into the options of fully automated intralogistics. The largest exhibit on display is a picking system with an integrated automated lidding…