Press release

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Faster – More Efficient

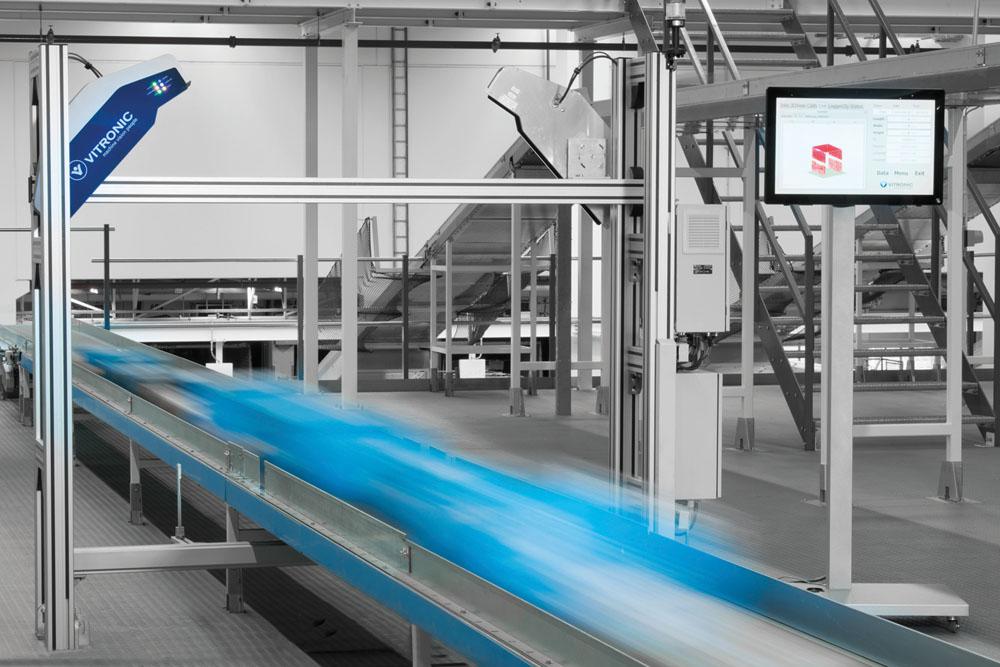

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all ambitious inspection tasks e.g. on car parts, axle components and car battery enclosures.100% Weld Seams – Maximum Efficiency

Faulty weld seams have severe consequences for automobile production, in particular on safety-critical components. Recalls may run into millions, let alone the resulting loss of reputation. Thanks to VITRONIC’s VIRO WSI, only perfectly welded components will be passed into the manufacturing process.

More Compact – Faster – More Efficient

The new generation of sensors for the VIRO WSI system is available in two different designs: a 30 mm wide field of view for MIG/MAG welded and brazed seams and a 14 mm wide field of view for laser welded and brazed seams with their very finite seam geometries. Through the compact design of the sensors, the inspection system also reaches hard-to-access areas and diagnoses defects as small as 0.1 millimeters. This newly deployed technology makes the new generation of sensors four times more powerful than the previous ones. Thus, it is possible to implement even shorter cycle capable of inspecting components from several different welding stations. With a resolution under 1 µm in depth, VIRO WSI can detect the tiniest defect. In addition, the rugged connection system featuring an easy push-pull-concept allows mounting of the sensors extremely easy.

Visualization of Defects and Process Optimization

With VITRONIC´s interactive visualization stations, defective components and seams are vividly displayed to the operator. The direct visualization on the line enables VIRO WSI to rapidly intervene in the upstream welding process. This leads to a sustainable reduction of errors, optimizes processes and reduces downtimes, reworking and outages.

ABOUT VITRONIC

VITRONIC is a world leading company for industrial image processing. The owner-managed corporate group develops innovative products and customized solutions for the growth areas of industry and logistics automation as well as traffic engineering. With more than 30 years of experience, VITRONIC offers an exceptional portfolio of systems and software for image and sensor-based quality testing, identification, traffic surveillance and toll collection.

The systems of VITRONIC make an important contribution to guarantee the highest quality and profitability in the production of automotive, photovoltaic and pharmaceutical companies. Its systems are used from companies acting in medical technology and pharmacy in more than 40 countries. In logistic centers and at cargo airports world-wide, the automatic ID-solutions of VITRONIC are responsible for an efficient acquisition and integration of consignment data and contribute to transparent flows of goods. For the transport sector, the company offers high-performance technologies to guarantee greater safety on the streets and to improve the traffic flow.

Since its foundation in 1984, VITRONIC grows steadily and is represented with 1,000 employees on four continents. In 2017, the group generated an overall performance of 172 million Euro.

Contact:

Birgit Voigt

Phone: +49 611 7152 7072

birgit.voigt@vitronic.com

www.vitronic.com

VITRONIC Dr.-Ing. Stein

Bildbearbeitungssysteme GmbH

Hasengartenstr. 14

D-65189 Wiesbaden

Phone: +49 611 7152-0

Fax: +49 611 7152-133

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Faster – More Efficient here

News-ID: 1717591 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…

More Releases for VIRO

Household VR Gym and Fitness Market Size, and Research Report 2022 by Production …

The market trend, market share, size, and forecast are the primary areas of focus for the worldwide Household VR Gym and Fitness market in 2020. This professional research of the global market for home VR gyms and fitness is succinct and to the point. Data indicates that virtual reality exercises can burn just as many calories as conventional exercises. Additionally, some games can make you forget you are exercising at…

Household VR Gym and Fitness Market 2022: Analysis by Top Key Players - VirZOOM, …

Household VR Gym and Fitness Market Scope and Overview 2022

This study provides a comprehensive examination of the global Household VR Gym and Fitness industry. The study includes all of the necessary data, which was gathered through extensive primary and secondary research. The market analysis includes data from segments such as type, industry, channel, and others; market volume and value are also included for each segment. The study also looks at…

Household VR Gym and Fitness Market Technology, Recent Trends, Demand, Future Gr …

Household VR Gym and Fitness Market Analysis By Product Type, By Application, By Region and Key Players - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2022 to 2028

A recent report by Infinity Business Insights titled Household VR Gym and Fitness market,"" gives a specialist and in-depth summary of the existing and prospective Household VR Gym and Fitness market, as well as a study of Specific Requirements, display structure,…

Household VR Fitness Solutions Market is Estimated to Grow at a Significant CAGR …

Qualitative research method is used in this Household VR Fitness Solutions market research to provide in-depth understanding of customer wants and needs. It sheds light on competitors’ future action plans for the forecast period 2021-2027. Customers’ buying habits, economic conditions, industry patterns, entire market condition business consulting elements are all the significant factors covered in this market analysis report. Key facts depicted in this business report help market participants to…

SONGWRITER JON UDELL RELEASES NEW SINGLE, “MOOREA”, WITH VOCALS BY VIRO – …

SONGWRITER JON UDELL RELEASES NEW SINGLE, “MOOREA”, WITH VOCALS BY VIRO – OUT AUGUST 13, 2021

PRODUCED BY WORLD-RENOWNED RECORD PRODUCER DITO GODWIN

Los Angeles, CA (August 13th) -- Los Angeles-based songwriter, Jon Udell, officially releases his new single, “Moorea”, August 13 2021- listen to the song on all platforms, including Spotify.“Moorea” beautifully encompasses Jon Udell’s songwriting style, as vocalist Viro showcases her stunning voice in the song and sings of the…

Household VR Gym and Fitness Market Outlook On Emerging Application, Revolutiona …

The global Household VR Gym and Fitness market 2020 mainly focuses on the market trend, market share, size and forecast. It is a brief and professional analysis on the current scenario of the Global Household VR Gym and Fitness market.

The report on Household VR Gym and Fitness market is a comprehensive study on global market analysis and insights. The report focuses on the emerging trends in the global and regional…