Press release

CeMAT 2008 Trade Fair in Hannover, Germany: AMI Highlights Customized Conveying Solutions

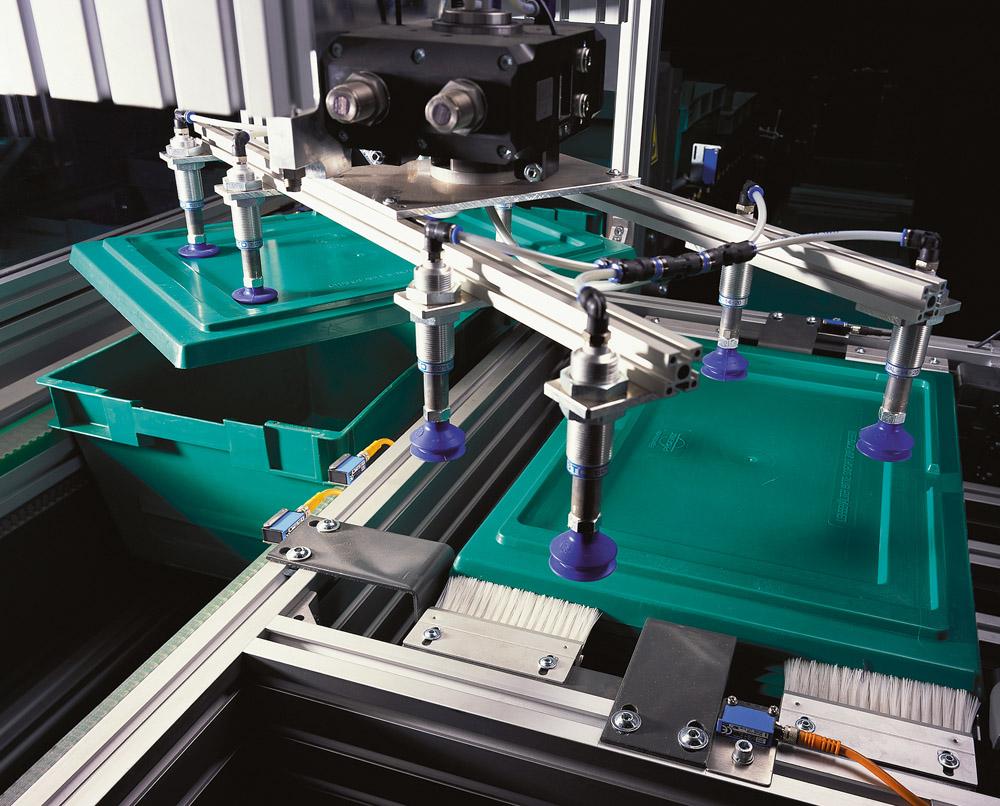

Conveying technology and material handling systems for a wide range of applications will be showcased by AMI Förder- und Lagertechnik GmbH at this year’s CeMAT trade fair in Hannover, Germany. From May 27 to 31 visitors of the 100 m² Stand H 44 in Hall 27 will gain insights into the options of fully automated intralogistics. The largest exhibit on display is a picking system with an integrated automated lidding machine.“The closing of picking bins with a cover by hand is a time-consuming and non-value-adding activity. Our automated lidding machine taps considerable potential for optimization in this process,” explains Stefan Brenner, Managing Director/CEO of AMI. The picking system for bins showcased at CeMAT consists of a conveyor technology loop with an integrated automated lidding machine. The AMI lidding machine’s most convincing feature is its high throughput rate: the system is capable of closing up to 1,800 containers per hour. If configured accordingly, it is also capable of handling containers of different sizes. At the trade fair AMI will also showcase current projects for customers like Krombacher, Orsay, Schober, and Bürkert. AMI recently developed a pallet control system for Krombacher, for example. At Schober, AMI was responsible for integrating on-site conveying technology and workstations. “To remain competitive in today’s markets, automation of the order picking, transport, and handling processes is becoming ever more important. Consequently, we anticipate visitors to the show to be very interested in our innovative and customized conveying technology,” explains Stefan Brenner.

Company Contact

Mr Stefan Brenner • AMI Förder- und Lagertechnik GmbH

Am Wehrholz • 57642 Alpenrod • Germany

Telefon: +49 2662-9565-0 • Fax: +49 2662-939775

E-Mail: info@ami-alpenrod.de • Internet: www.foerdertechnik.net

Media Contact

Ms Tanja Planko • additiv pr

Steinweg 43a • 56410 Montabaur • Germany

Telefon: +49 2602-950 99-15 • Fax: +49 2602-950 99-17

E-Mail: tp@additiv-pr.de • Internet: www.additiv-pr.de

AMI Förder- und Lagertechnik GmbH – The Company

Founded in 1987, AMI Förder- und Lagertechnik GmbH with its 50 employees is a leading provider of handling equipment and systems for material flow in areas ranging from incoming goods to manufacturing, order picking and final inspection to shipping. The product range extends from light to heavy-duty conveyors for loads of up to 2,500 kilos. AMI provides customers with planning, engineering, manufacturing and installation from a single source. The conveyor technology experts at AMI plan and implement turn-key conveyor systems or upgrade existing systems based on comprehensive analyses, services offered regardless of whether the solution sought is manual, semi-automatic or full automatic. AMI also integrates material flow computers, warehouse management computers, data networks, and merchandise information systems. The AMI list of references includes noted customers from every branch, such as Deutsche Post, dm, LUXAIR, Sanicare, REWE, Siemens, Procter & Gamble, Orsay and Nestlé.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CeMAT 2008 Trade Fair in Hannover, Germany: AMI Highlights Customized Conveying Solutions here

News-ID: 41409 • Views: …

More Releases for CeMAT

Lydia Voice Market to Witness Notable Growth by 2027 Covid-19 Analysis | CeMAT, …

This in-detail Lydia Voice market analysis presents a review on crucial industries, which are greatly helping to impel the market growth. This market study report further depicts mergers, acquisitions amid startups, strategies, product launchings and collaborations followed by industry players of the market. Industry players of the market take more efforts to go with new technology to get a competitive advantage over the cut-throat competition of the market. In order…

Review: VITRONIC at CeMAT exhibition 2011: Camera systems for data acquisition i …

Wiesbaden, 12th May 2011 – VITRONIC presented camera-based Auto-ID systems at this year’s CeMAT in Hannover from 2nd to 6th May. These camera systems outmatch conventional laser scanners regarding the acquisition of customer- and object based data of goods in intralogistics.

VIPAC systems for manual, semi-automatic and fully automatic data acquisition have been presented at the booth. These systems acquire data along the entire process chain in intralogistics, i.e. in incoming…

Wind of Change for Intralogistics - Bizerba at the CeMAT 2011 in Hannover (hall …

Balingen, 2nd May 2011 – Driven by globalisation companies are confronted with dynamic challenges. The goal is to constantly improve the logistical flows of material and goods that take place on the company grounds and to reduce the time required for the processing of orders. At the CeMAT 2011, one of the most important intralogistics fairs in the world, Bizerba is going to present from 2nd to 6th May system…

PSI Presents Innovative Logistics Solutions at the CeMAT

Berlin, 1 April 2011 – Under the motto of “Smart Grid for Logistics“,PSI subsidiary PSI Logistics GmbH will be presenting new software developments for the logistics sector at the CeMAT 2011 from 2 to 6 May in Hannover (Hall 27, Stand D18). Along with new modules and functionalities, new schools of thought for logistics as well as forums on the hot subjects of intra logistics will round out the company’s…

VITRONIC presents at this year’s CeMAT: Advantages of camera systems for data …

Highest Read Rates for Maximum Throughput

Wiesbaden, March 23rd 2011 – In intralogistics, customer-related and object-related data of goods is acquired and processed at different locations. Currently, laser scanners and camera systems are used for this purpose. However, the future belongs to the camera technology that provides significant advantages: it increases the degree of automation, accelerates processes, improves the efficiency and productivity with respect to personnel placement and reduces the logistics…

Schaltbau GmbH at the CeMAT in Hanover

Munich, 18/02/2011: At the CeMAT in Hanover (2nd – 6th May 2011) Schaltbau GmbH presents charging connectors, combination contactors and emergency cut-off switches. These products are used first and foremost in forklift trucks. The main exhibits are the charging connectors. The LV Series is modular, thus permitting scalable solutions between vehicle, battery and charger. The LV500 charging connector assures permanent operating currents of up to 500 Amperes, and has been…