Press release

Automated 3D Volume Measurement and Defect Detection

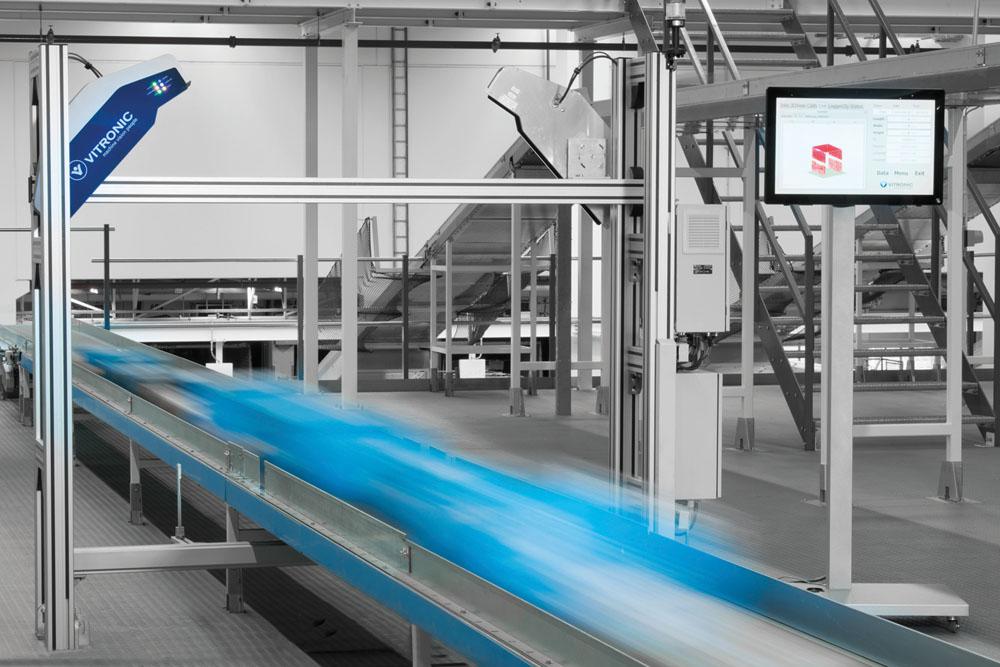

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system combines innovative laser and camera technology in a highly precise and reliable end-to-end solution. VOLUMEChd measures the volume of both rectangular and irregularly shaped objects as they are transported by conveyor belts and sorters. High transport speeds of up to 3 m/s ensure optimum throughput rates.

VOLUMEChd makes it possible to reliably measure packages up to a maximum size of 1,000 x 1,000 x 2,500 mm (HxWxL). Thanks to the unique camera-based laser measurement, it is even possible to reliably determine the volume of very small and extremely flat objects – even including dark objects. A high measurement accuracy of 5 x 5 x 5 mm for rectangular objects and 10 x 10 x 10 mm for other objects is achieved.

In addition to volume measurement, the system also detects defects on boxes, such as bulges and dents, on five object sides. This prevents malfunctioning of automated warehouse technology and reductions in throughput when storing boxes in automated high-bay warehouses, for example.

VOLUMEChd can be used as a standalone solution or as an integrated part of VIPAC Auto-ID systems. As there are no moving parts, the solution is entirely maintenance free.

Process optimization through precise volume data

When working with VOLUMEChd, securely stored data that cannot be manipulated can be used to automatically create invoices and customer parcel information can be compared with the measured data. The volume data can also be used as a basis for calculating transport capacities and optimizing vehicle loads and route planning. It can furthermore be used to generate statistics and improve internal goods flows, as well as to check company price structures and logistics processes.

The new VOLUMEChd was already exhibited at the CeMAT in Hanover from May 19-23, 2014, where it received great interest from trade visitors. The new product video on YouTube provides a clear overview of the system’s key performance features and benefits.

VITRONIC YOUTUBE channel:

http://www.youtube.com/watch?v=5cP0AYm1zbs

Further information:

http://www.vitronic.de/en/industry-logistics.html

VITRONIC is an owner-managed group of companies comprising VITRONIC GmbH with its headquarters in Wiesbaden and several international subsidiaries. The group is a world leader in industrial machine vision covering a wide spectrum from standard products with customer-specific upgradeable modules to individually customized solutions in its core sectors of industry, logistics and traffic technology. Since VITRON-IC was founded in 1984 it has grown on the strength of its own resources. Today we are represented by more than 600 employees on four continents. In 2013, the VITRONIC Group generated total revenue of 83 million euros. VITRONIC products are state-of-the-art and are guaranteed to offer our customers maximum benefits. The group invests over 10 percent of total revenue each year in research and develop-ment. All VITRONIC solutions are designed and developed by ourselves and produced in Germany.

Our customers in the area of material flow, parcel logistics and mail order seek to optimize their logistics processes. VIPAC systems from VITRONIC can be integrated at any point along the process chain for the automatic capture of product data, package data and customer-specific data. VIPAC reads addresses, barcodes, 2D codes, customer-specific codes and plain text (OCR) with maximum read rates, and measures and weighs packages online. This information is sent directly to the connected ERP system or CRM solution. VIPAC systems are used by global logistics companies in the courier, express and parcel sector and in mail order, warehousing and distribution, and the manufacturing industry.

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden, Germany

Phone: +49 611 7152 0

Fax: +49 611 7152 133

Birgit Loeschner

Phone: +49 611 7152 261

birgit.loeschner@vitronic.com

www.vitronic.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated 3D Volume Measurement and Defect Detection here

News-ID: 289279 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…