Press release

A Global First: WEDA Dry Feeding Mixer Feeds out Fourfold

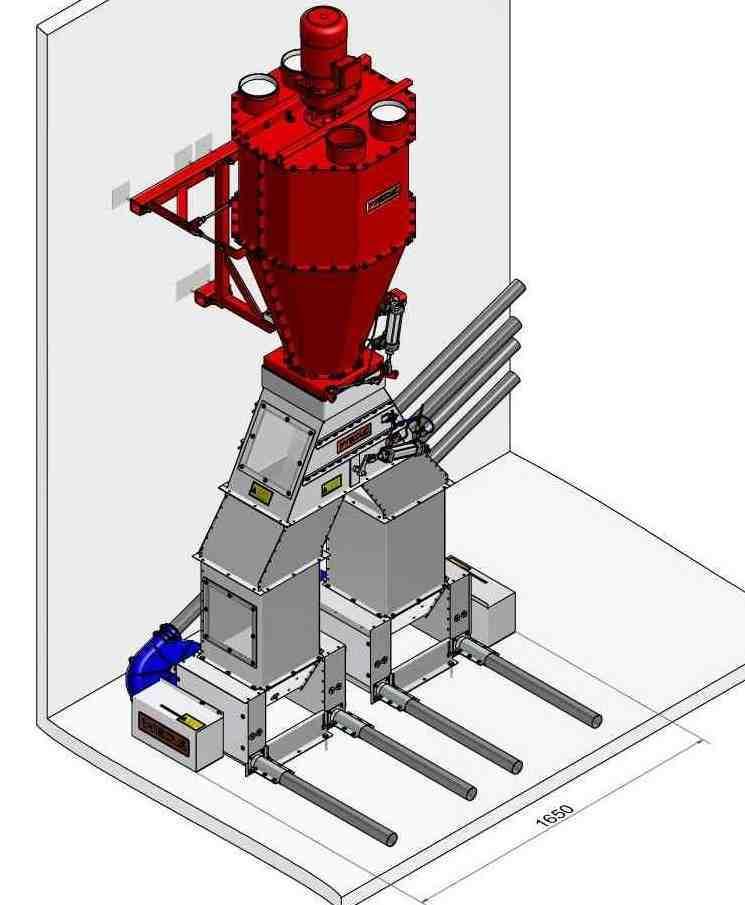

The “TM 100”. WEDA introduces the first dry mixer worldwide, which is able to distribute pigs’ feed to four circuits.

The innovative WEDA technology thus ensures an efficient multi-phase feeding process: with the aid of the “TM” the running times of the feed chains are clearly shortened while the throughput of the feed is increased. This way it is now possible to construct the mixing unit in such a way that the feed centre requires just one feeding interval and that feeding does not have to take place twice a day. The WEDA mixer, however, also saves costs as less devices will be required for the processing of the feed amount. By the simple upgrading from the 40-kilo to the 100-kilo version, a lot of time is saved in the feeding process – especially when the established 80-kilo mixes are fed out.

With the development of the feeding distributor, the Lower Saxon market leader relies on the modular construction of the proven WEDA components with just a small “foot print”. Therefore, - besides the costs – pig farmers also save space inside the animal house by the use of the WEDA mixer. The dimensions of the stationary system are compact so that the four feed lines can be charged in a space saving way. Both systems only require a floor space of approx. 1.65 m x 1.65 m. Already available WEDA units can be problem-free converted into the TM system.

The construction of the filling hopper guarantees a high degree of feed hygiene as there are no parts on the inside of the hopper which form an obstacle by encouraging the formation of feed bridges. The cleaning also becomes easier this way; the dry mixer of WEDA can be simply washed out with water and without the addition of cleaning agents.

For more than 70 years, WEDA’s name stands for innovation and reliability. Originally founded as an enterprise for the manufacture of wood gas generators, Dammann & Westerkamp GmbH (WEDA) have meanwhile become global market leaders in the domain of liquid feeding with more than 130 members of staff at their headquarters at Lutten. The WEDA company owns locations in almost 50 countries on all continents.

In their function as full providers in the field of modern pig managements, WEDA – besides the domains of feeding technology and house equipment – also attend upon the segments of ventilation technology and liquid manure treatment. WEDA possess more than two dozens of patents.

In 1996 – as the first enterprise of the branch – WEDA received the certification according to the international quality standards, DIN EN ISO 9000 ff. In 2001, the companies of WEDA and of Erich Stallkamp ESTA GmbH founded the WELTEC BIOPOWER GmbH enterprise.

WELtec BioPower GmbH

Carsten Bergstedt

Head of Marketing

Am Bahnhof 10

49424 Lutten

Phone: +49 4441.8705.65

Email: c.bergstedt@weda.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Global First: WEDA Dry Feeding Mixer Feeds out Fourfold here

News-ID: 173441 • Views: …

More Releases from WEDA Dammann & Westerkamp GmbH

The Downpipe Cleaning for Liquid Feeding Systems

WEDA-EUROTIER-NOVELTY No. 3

Feeding Technology: „WACS“

Isn’t almost every pig farmer familiar with the laborious and time-consuming cleaning of downpipes in liquid feeding systems, e.g, by means of a rinsing device? From now on, the new computer controlled WACS of WEDA makes dirty downpipes a thing of the past.

WEDA’s new development, the WACS (Weda Active Cleaning System) ensures automatic cleaning of the downpipes in liquid feeding units by means of an air…

Fermentation Almost by Itself

WEDA-EUROTIER NOVELTY No. 2

Feeding Technology: „WEDA Fermi 4PX“

Until now, liquid feeding units with fermentation have been able to control the fer- mentation process, however, not without additional manual adaptations on behalf of the unit operators. WEDA have developed a fermentation software, which takes off a large part of this work for the user and consequently saves a lot of time and effort.

For an optimal fermentation, the…

Instrument Panel in the Pig House

WEDA-EUROTIER NOVELTY No. 1

Management: „Dashboard for Excellent 4PX“

WEDA have developed a software solution, which offers all relevant data of the feeding computer at a glance. Thereby, the user is already at a very early stage in a position to detect if problems within his animal stock are beginning to emerge, and can intervene directly.

Until now, within the frame of his daily, time-consuming routine procedure, the user of a…

More Releases for Lutten

The Downpipe Cleaning for Liquid Feeding Systems

WEDA-EUROTIER-NOVELTY No. 3

Feeding Technology: „WACS“

Isn’t almost every pig farmer familiar with the laborious and time-consuming cleaning of downpipes in liquid feeding systems, e.g, by means of a rinsing device? From now on, the new computer controlled WACS of WEDA makes dirty downpipes a thing of the past.

WEDA’s new development, the WACS (Weda Active Cleaning System) ensures automatic cleaning of the downpipes in liquid feeding units by means of an air…

WEDA Innovation wins DLG Silver Medal

„Boar Stub” feed genders according to recipe

The message about the award of a medal of the German Agricultural Association (DLG) was received with great pleasure by the Lutten constructors of animal houses, WEDA Dammann & Westerkamp. „A small step for WEDA, – a great one for boar fattening”, is Andreas Hüttemeyer’s, – programmer at WEDA’s – reaction on this distinction.

With this award-winning EuroTier novelty, the full-service…

Sow Managements: New WEDA Pen offers more freedom of movement

The legal amendments for sow managements have led to stormy discussions about the wellbeing of animals. Amongst others, one of the topics was concerned with more space to enable more freedom of movement for sows in farrowing pens. In some countries, like for example in Austria, farmers will in future even be obliged by law in this respect.

In order to provide a solution to this, WEDA Dammann & Westerkamp…

New WEDA Container: small feed amounts – huge impact

WEDA – Dammann & Westerkamp from Lutten are introducing a new type of container for liquid feeding systems, which enables the dosification of smallest feed amounts for pigs.

The special feature of the „QXS“ is the cuboid-shaped „sump“ of the container. Furthermore, the developers of the comprehensive suppliers for pig managements have adopted the modular construction manner of the proven QS container wall system. This standardization facilitates container sizes…

DLG Ranking: WEDA rises to the Top Three

For 16 years now, the German Agricultural Society (DLG) has been investigating the image of agricultural enterprises. In November, the 2011 industry barometer was published. In the current ranking, the company of WEDA Dammann & Westerkamp GmbH who has been continuously improving is now sharing the third position of the category of “Technology

in Animal Management” with the Swedish enterprise of de Laval. In the category “Pig Management“, WEDA even achieved…

New WEDA 10 cubic metres CCM Dosificator

The round dosificator for dry and wet pigs‘ feed components of WEDA Dammann & Westerkamp is now additionally available in two spacious variations of six and ten cubic metres of intermediate storage capacity.

Since the early eighties, WEDA of Lutten have been the only providers and producers for intermediate storage containers of glass fibre reinforced plastic (GFK) for CCM and wet grain. These properties make GFK an ideally suited material.…