Press release

Do you know the most cost-efficiency bimetallic finned tube?

As a key heat transfer element, the finned tube's core function lies in balancing the difference in heat transfer coefficients between the two fluid sides of a heat exchanger. By installing fins on the side with a lower heat transfer coefficient, the heat transfer area is enlarged. It is indispensable in applications requiring enhanced heat transfer, such as boiler economizers and air coolers.In industrial sectors like power, chemical, petrochemical, air conditioning, and refrigeration engineering, efficient heat exchange equipment is crucial for ensuring system stability, energy conservation, and emission reduction.

The core mission of a heat exchanger is to transfer heat quickly and efficiently. When heat exchange occurs between a gas and a liquid, or between two gases, the overall heat transfer efficiency is often low because the heat transfer coefficient on the gas side is typically much lower than on the liquid side.

To address this issue, engineers attach thin metal sheets called "fins" to the outer surface of the heat exchange tubes. These seemingly simple metal pieces significantly increase the contact area between the tube and the air, effectively breaking through the thermal resistance bottleneck on the gas side and thereby markedly enhancing heat transfer efficiency.

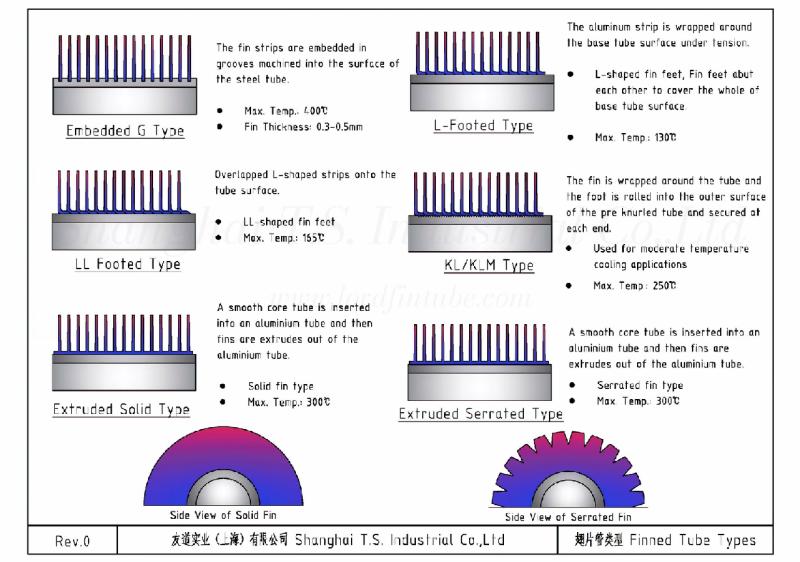

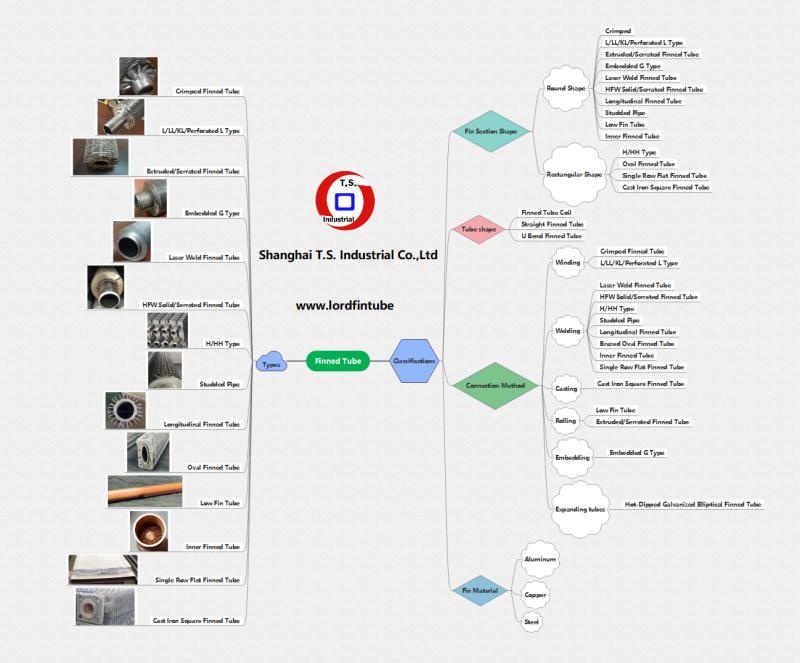

There are various types of bimetallic composite finned tubes on the market, including L-type, LL-type, KL-type wound fin tubes, extruded fin tubes, and embedded fin tubes. Among them, the embedded fin tube stands out with its unique design and excellent overall performance, earning the title of the true "king of cost-effectiveness."

Currently, there are five main types of bimetallic composite finned tubes widely used in industry, each with its unique manufacturing process and performance characteristics.

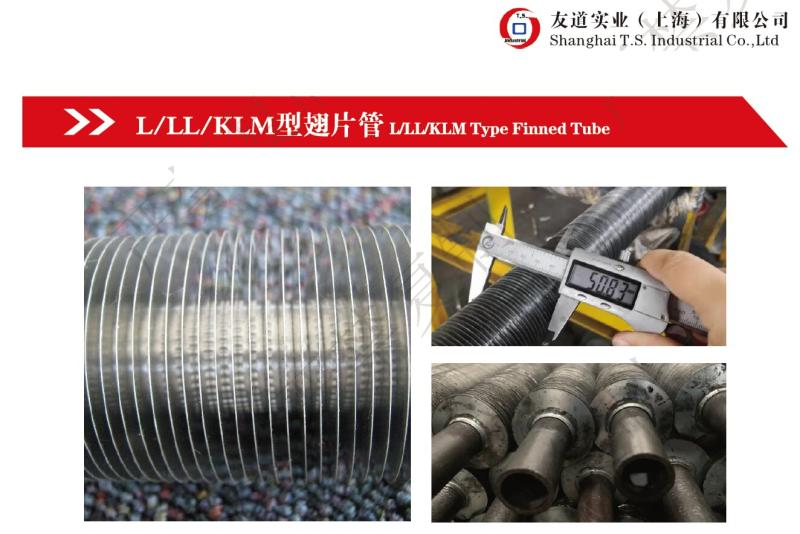

L-type, LL-type, and KL-type wound fin tubes belong to the family of mechanically attached fin tubes. They are made by folding an aluminum strip into a specific shape (e.g., L-shape) and helically winding it under tension onto the surface of the base tube.

- The operating temperature of L-type fin tubes typically does not exceed 150°C.

https://www.lordfintube.com/l-foot-finned-tube_648.html

- The LL-type is an improved version of the L-type, with the fin root providing better coverage of the base tube, raising its maximum operating temperature to about 170°C.

https://www.lordfintube.com/ll-finned-tube_647.html

- The KL-type goes a step further. The base tube surface is pre-knurled, and the fin root is also knurled after winding, enhancing the bonding strength and allowing operating temperatures up to 230-250°C.

https://www.lordfintube.com/kl-type-fin-tube_1148.html

Extruded fin tubes (rolled fin tubes) are manufactured by co-rolling an aluminum sleeve over an inner steel liner tube using a specialized mill, causing the aluminum to plastically flow and form fins. This process achieves a metallurgical bond between the fins and the base tube, resulting in high heat transfer efficiency and a smooth, neat appearance. The maximum service temperature of extruded fin tubes can reach 300°C. However, due to the need for expensive specialized rolling mills, the processing cost of this type of fin tube is also the highest among all types.

https://www.lordfintube.com/extruded-fin-tube_650.html

Embedded fin tubes employ a unique processing technique: spiral grooves are first machined onto the steel tube, and then the fin strip is embedded and wound into these grooves. This structure ensures tight contact between the fin and the base tube while providing good bonding strength through mechanical interlocking.

Among the fin tubes mentioned above, the embedded fin tube stands out as the undisputed "king of cost-effectiveness." This stems from its choice of fin material: unlike the other types, embedded fin tubes can use copper as the fin material in addition to aluminum.

The maximum service temperature of copper embedded fin tubes can exceed 300°C, significantly higher than that of L-type, LL-type, KL-type wound fin tubes and extruded fin tubes. This enables them to adapt to a wider range of industrial applications, from conventional heating to medium-high temperature environments.

https://www.lordfintube.com/copper-embedded-finned-tube_1335.html

Compared to extruded fin tubes, the processing cost of embedded fin tubes is substantially lower. The extrusion process requires expensive specialized rolling mills, whereas the inlaying process can be completed on general-purpose equipment, making both equipment investment and production costs more economical.

The high cost-effectiveness of embedded fin tubes originates from their unique design and manufacturing advantages.

The fin root is securely locked into the spiral groove of the base tube, forming a mechanical interlock with high bonding strength. This structure resists loosening even after long-term thermal cycling, ensuring long-term stable heat transfer performance. The high bonding strength results in extremely low thermal resistance. Studies show that the embedded structure can provide heat transfer efficiency approximating that of a metallurgical bond, allowing heat to be efficiently transferred from the base tube to the fins.

Beyond performance advantages, embedded fin tubes also demonstrate excellent flexibility in material selection.

Aluminum fins are the most common choice. With a thermal conductivity of about 237 W/m·K, although lower than copper, aluminum offers advantages of light weight and low cost, making it suitable for most conventional industrial applications.

For special applications requiring higher thermal conductivity, the inlaying process can also utilize copper fins. With a thermal conductivity as high as 400 W/m·K, copper fins improve heat transfer efficiency by approximately 60% compared to aluminum fins, making them particularly suitable for situations demanding extreme heat exchange efficiency.

Whether using aluminum or copper fins, the inlaying process can form reliable connections with base tubes of various materials (carbon steel, stainless steel, alloy steel, etc.), meeting the requirements of different corrosive environments, pressure ratings, and temperature conditions.

We have a variety of finned tube types available for selection, especially embedded fin tubes. Our embedded fin tubes can utilize not only aluminum fins but also copper fins for the inlaying process.

Company Name: Shanghai T.S. Industrial Co. Ltd

Contact Name: Miss Estela

Contact Number: 0086-021-66030009

Address: No.2, Lane 1588 Youyi Road, Baoshan, Shanghai, The P. R. of China. Post. 201999

Email: estela@lordfintube.com

Website: https://www.lordfintube.com/

Shanghai T.S. Industrial Co., Ltd is a leading company specializing in the production of finned tubes, tube sheet, U bend tubes, and helical coiled pipe used in heat exchangers, boiler economizers, coolers, and heaters. Our focus is on supplying custom fin tubes, finned pipes, and tube sheets in various material configurations to enhance heat transfer rates and reduce operating costs. With our advanced production capabilities and commitment to quality, we deliver innovative and efficient solutions tailored to meet the specific needs of our clients in the heat exchanger and boiler industries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Do you know the most cost-efficiency bimetallic finned tube? here

News-ID: 4354652 • Views: …

More Releases from Shanghai T.S. Industrial Co.,Ltd

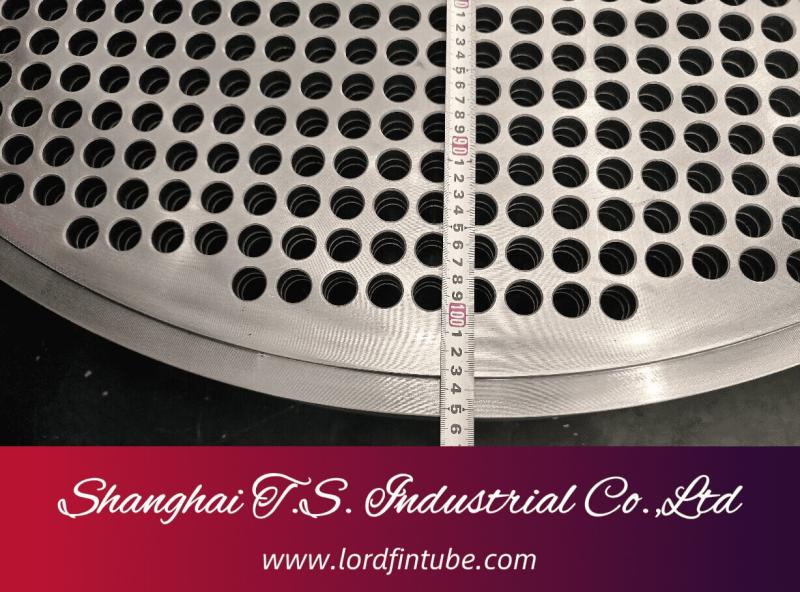

Lordfintube--Tubesheet for Shell and Tube Heat Exchanger

Within the complex internal structure of a shell and tube heat exchanger, the tube sheet plays a pivotal role-it is not only the supporting skeleton for the tube bundle but also the critical barrier separating the tube-side and shell-side media. A well-designed and precisely manufactured tube sheet directly determines the efficiency, safety, and service life of the heat exchanger. As a professional manufacturer of heat exchanger tube sheets and baffles,…

What's the Difference between L/LL/KL Type Finned Tube?

In an era where energy efficiency is increasingly vital to industrial operations, even minor performance improvements in heat exchangers-the core equipment for thermal energy recovery and management-can translate into significant operational cost savings. At the heart of most heat exchangers lies the finned tube, whose type selection directly dictates the entire system's efficiency, service life, and reliability. This article provides an in-depth analysis of three widely used finned tube types:…

A Comprehensive Guide to Finned Tube Types |Heat Exchanger

Finned tubes are indispensable core components within heat exchangers across various sectors, including power engineering, chemical production, petroleum refining, air conditioning engineering, and refrigeration. By adding different types of fins to the internal or external surface of a base bare tube, the heat transfer area is significantly increased, leading to a substantial enhancement in heat exchange efficiency. Particularly in gas-liquid heat exchange scenarios, finned tubes effectively balance the difference in…

Shanghai T.S. Industrial Co.,Ltd focuses on Finned Tubes, Tube Sheets and Heat E …

Shanghai T.S. Industrial Co., Ltd is a leading company specializing in Finned tubes, U bend tubes, and Tube sheets used in Heat Exchangers, Boiler Economizers, Coolers, and Heaters. We focus on supplying custom fin tubes, finned pipes, and tube sheets in various material configurations that enhance heat transfer rates and reduce operating costs.

T.S. Industrial Key Products Details:

1. Finned Tube

Finned tubes are composed of fins and base tubes. As heat exchange…

More Releases for W/m·K

SINOYQX Launches Aerogel-Melamine Foam Thermal Insulation Roll | 0.016 W/m·K Ul …

Chengdu, China - [28/10, 2025]

SINOYQX, a leading innovator in melamine-based polymeric materials, today announced the launch of its new Aerogel-Melamine Foam Thermal Insulation Roll, a breakthrough composite that integrates ultra-low thermal conductivity, inherent flame resistance, and superior flexibility in one lightweight form.

This new material sets a fresh benchmark for high-performance flexible insulation solutions across the energy, mobility, and aerospace industries.

🔹 A Flexible Insulation Revolution

Engineered with proprietary aerogel-infiltration composite technology, the…

YINCAE Launches Diamond Underfill UF 158D with 8 W/m·K Thermal Conductivity

09/23/2025 (Albany, NY) - YINCAE, a leader in advanced electronic materials, has introduced Diamond Underfill UF 158D, delivering 8 W/m·K thermal conductivity-a new standard in heat dissipation for advanced semiconductor packaging.

Built with nano-engineered diamond particles, UF 158D combines high thermal performance with excellent mechanical reliability, low CTE mismatch, and strong adhesion. It is optimized for flip-chip, 2.5D/3D packaging, and high-density interconnects, reducing solder fatigue and extending device lifetime.

"UF 158D…

Structural Glass Wall System Market Set for Explosive Growth| Dorma, NanaWall Sy …

Advance Market Analytics published a new research publication on "Structural Glass Wall System Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Structural Glass Wall System market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive…

W CUSHION DESIGN COMPETITION AT WOOBAR, W RETREAT KOH SAMUI

Koh Samui, Thailand – WOOBAR @W Retreat Koh Samui, a heavenly haven in the Gulf of Thailand, announced its first ever cushion design competition. The contest, which attracted entries from across the region, honors design professionals who incorporate WOOBAR into innovative, original and outspoken designs.

The Grand prize winner will receive a 4-night stay at W Retreat Koh Samui worth THB100,000 and a chance to join WOOBAR re-launch party where…

ROC Polska wkracza w 2013 rok z nowym rozwiązaniem do raportowania w SAP w wers …

Globalny partner SAP – ROC Polska, zakończył proces lokalizacji dla rynku polskiego aplikacji Easy Reporter, autorskiego narzędzia do generowania raportów firmy SpinifexIT. Odpowiadając na zapotrzebowanie rynku, z nadejściem 2013 roku umożliwia także polskim firmom korzystanie z zalet tego rozwiązania.

Easy Reporter jest odpowiedzią na zapotrzebowanie działów HR na narzędzie zastępujące żmudne przenoszenie danych z systemu SAP w celu tworzenia raportów dla kierownictwa. Aplikacja generuje raporty łączące dane osobowe, płacowe i czas…

Sektor biotechnologii w farmacji: boom spodziewany dopiero w 2011 roku

Obecnie sektor biotechnologii znajdującej zastosowanie w farmacji i medycynie (tzw. „czerwonej biotechnologii”) rozwija się w Polsce w umiarkowanym tempie, wynika z najnowszego raportu firmy badawczej PMR „Innowacje biotechnologiczne w przemyśle farmaceutycznym w Polsce 2009”. W 2008 r. przychody tego sektora spadły nawet w porównaniu do poprzedniego roku, co było spowodowane gorszymi wynikami Biotonu, największej polskiej firmy biotechnologicznej. Warto jednak zaznaczyć, że firmy biotechnologiczne pracują obecnie intensywnie nad nowymi produktami, których…