Press release

What's the Difference between L/LL/KL Type Finned Tube?

In an era where energy efficiency is increasingly vital to industrial operations, even minor performance improvements in heat exchangers-the core equipment for thermal energy recovery and management-can translate into significant operational cost savings. At the heart of most heat exchangers lies the finned tube, whose type selection directly dictates the entire system's efficiency, service life, and reliability. This article provides an in-depth analysis of three widely used finned tube types: L, LL, and KL.Why Finned Tube Selection is Critical

In simple terms, finned tubes dramatically enhance heat transfer efficiency by expanding the available surface area for heat exchange. However, not all finned tubes perform equally. The core differentiator lies in the manufacturing process that bonds the fins to the base tube. The quality of this bond is paramount; it determines how effectively heat is conducted and whether the assembly will remain intact under long-term operation. An inappropriate choice can lead to diminished efficiency at best, and at worst, cause equipment failure, leaks, and substantial financial loss.

Introduction of L/LL/KL Type Finned Tubes

1. L-Type Finned Tube

https://www.lordfintube.com/l-foot-finned-tube_648.html

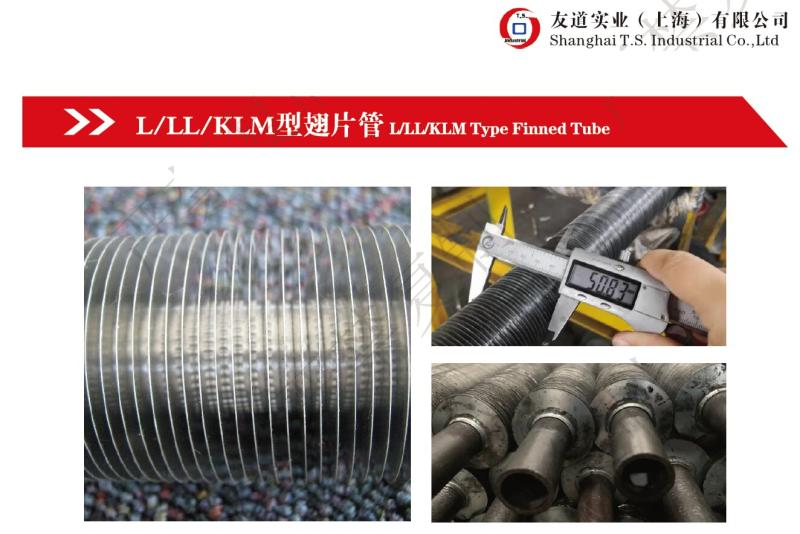

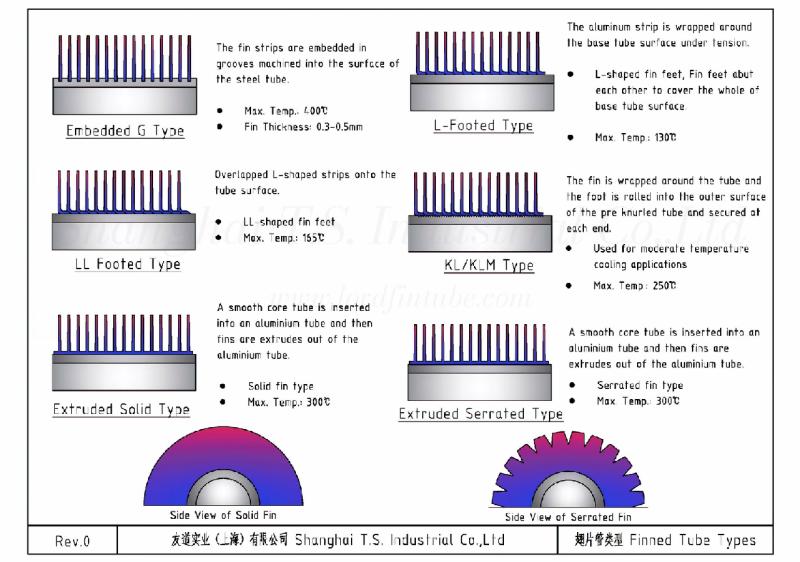

The L-Type finned tube is a classic industry solution. Its manufacturing process involves spirally winding an L-shaped metal strip (typically aluminum) under tension onto a base tube (e.g., carbon steel).

Its primary advantages are a simple manufacturing process, low production cost, and fast delivery times.

However, this "tension-wound" method has inherent limitations. When the operating temperature exceeds 130°C or the tube experiences frequent thermal cycling, the differing coefficients of thermal expansion between the base tube and the fin material can cause microscopic gaps to form at the interface. These gaps create significant contact thermal resistance, leading to a notable drop in heat transfer efficiency. Furthermore, these gaps are susceptible to corrosion, compromising the tube's service life. Consequently, the L-Type is an economical choice for stable, low-temperature applications where budget is a primary concern.

2. LL-Type Finned Tube

https://www.lordfintube.com/ll-finned-tube_647.html

As an evolution of the L-Type, the LL-Type finned tube introduces a crucial manufacturing advancement: the fin root is wrapped to fully encompass and cover the base tube's surface. This design elegantly eliminates the potential air channels present at the root of the L-Type tube.

This structure offers two key advantages:

First, it provides superior corrosion resistance, as the base tube is better protected from direct exposure to the process stream. Second, the more complete contact ensures more stable and overall better heat transfer performance compared to the L-Type. Its maximum service temperature is consequently raised to approximately 170°C.

For users in mildly corrosive environments, such as food processing or chemical industries, who also seek cost-effectiveness, the LL-Type finned tube is an excellent "balanced choice."

3. KL-Type Finned Tube

https://www.lordfintube.com/knurled-finned-tubes_646.html

When applications involve high temperatures, high pressure, vibration, or thermal shock, the KL-Type finned tube demonstrates its indispensable value. Its manufacturing process is the most complex: the base tube surface is first "knurled," and after the fins are wound, the fin roots are roller-grooved. This process plastically deforms the metals, creating a robust "mechanical interlock" structure.

This bonding method represents a qualitative leap in performance. The excellent bond strength virtually eliminates the risk of gaps forming due to thermal expansion and contraction. This results in the highest heat transfer efficiency among the three types and provides unparalleled long-term stability. KL-Type tubes can withstand temperatures up to 250°C or higher and can reliably endure severe thermal cycling and mechanical vibration.

Selection Guide: How to Choose the Right Type?

1. Temperature

• For continuous operating temperatures below 150°C, all three types can be considered.

• For temperatures between 150°C and 180°C, prioritize LL-Type or KL-Type.

• For temperatures exceeding 250°C, KL-Type is the only reliable option.

2. Operating Environment

• In humid or corrosive environments, prioritize the better-sealed LL-Type or the highest-strength KL-Type.

• For media prone to fouling or dust accumulation, consider KL-Type with wider fin spacing or other options like high-frequency welded tubes for a smoother, cleanable surface.

3. Cost Considerations

• For budget-conscious projects with mild operating conditions, the L-Type offers the lowest initial investment.

• For projects seeking a balance between corrosion resistance and cost, the LL-Type is the optimal compromise.

• For critical applications demanding high temperature capability and extreme reliability, the higher initial investment in KL-Type is justified over the total lifecycle of the equipment, thanks to its extended service life, minimal performance degradation, and near-zero maintenance costs.

Company Name: Shanghai T.S. Industrial Co. Ltd

Contact Name: Miss Estela

Contact Number: 0086-021-66030009

Address: No.2, Lane 1588 Youyi Road, Baoshan, Shanghai, The P. R. of China. Post. 201999

Email: estela@lordfintube.com

Website: https://www.lordfintube.com/

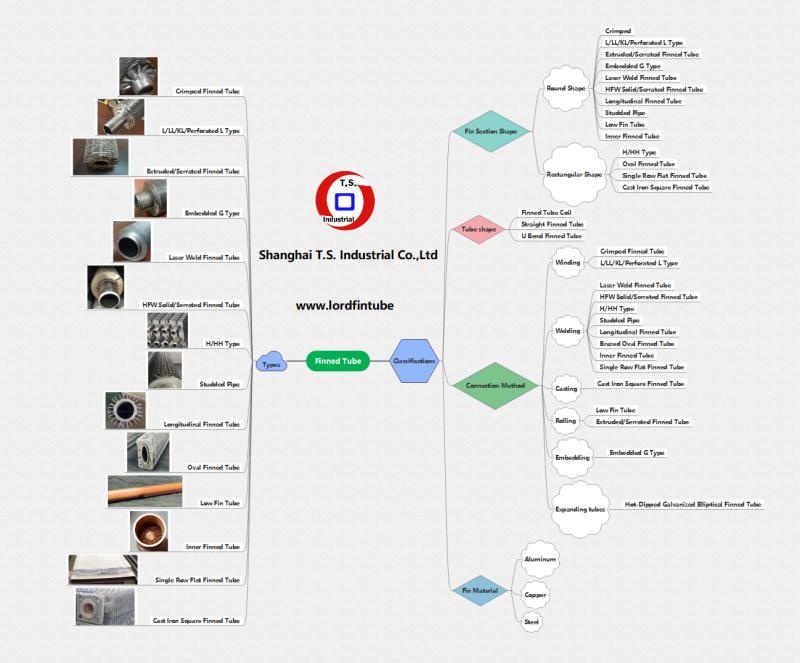

As a specialized supplier of finned tubes, we offer a diverse range of solutions to meet your specific needs:

• If you seek maximum cost-efficiency for stable operations, our L-Type tubes are the ideal choice.

• If you require enhanced corrosion resistance for more challenging environments, our LL-Type products provide an excellent balance.

• For critical applications involving high temperature, high pressure, or vibration, our KL-Type tubes deliver unmatched reliability to ensure system stability.

Our core business is providing a comprehensive portfolio of finned tube solutions for various heat exchangers, from economical models to high-performance versions. Our complete product matrix covers L, LL, and KL types, designed to precisely meet demands from standard heating to extreme industrial environments in petrochemical and power generation applications.

To learn more about our products, please visit our website.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release What's the Difference between L/LL/KL Type Finned Tube? here

News-ID: 4265062 • Views: …

More Releases from Shanghai T.S. Industrial Co.,Ltd

Do you know the most cost-efficiency bimetallic finned tube?

As a key heat transfer element, the finned tube's core function lies in balancing the difference in heat transfer coefficients between the two fluid sides of a heat exchanger. By installing fins on the side with a lower heat transfer coefficient, the heat transfer area is enlarged. It is indispensable in applications requiring enhanced heat transfer, such as boiler economizers and air coolers.

In industrial sectors like power, chemical, petrochemical, air…

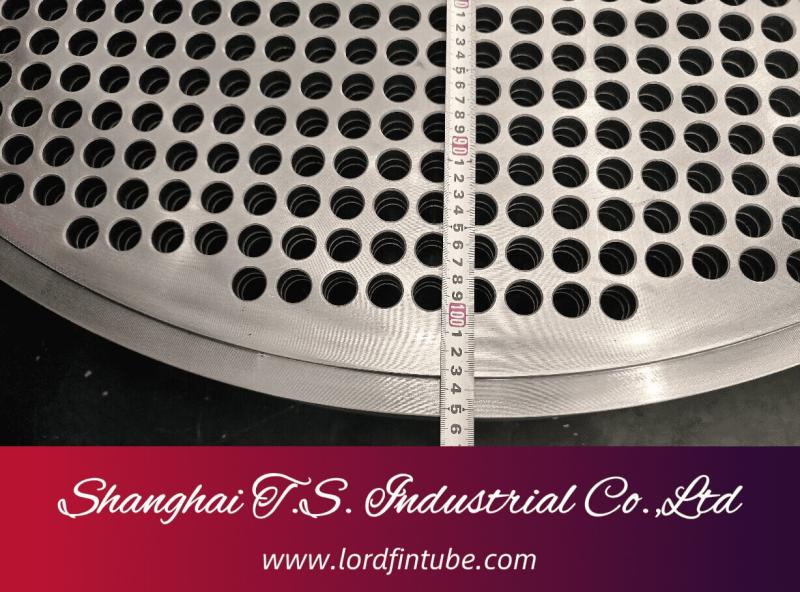

Lordfintube--Tubesheet for Shell and Tube Heat Exchanger

Within the complex internal structure of a shell and tube heat exchanger, the tube sheet plays a pivotal role-it is not only the supporting skeleton for the tube bundle but also the critical barrier separating the tube-side and shell-side media. A well-designed and precisely manufactured tube sheet directly determines the efficiency, safety, and service life of the heat exchanger. As a professional manufacturer of heat exchanger tube sheets and baffles,…

A Comprehensive Guide to Finned Tube Types |Heat Exchanger

Finned tubes are indispensable core components within heat exchangers across various sectors, including power engineering, chemical production, petroleum refining, air conditioning engineering, and refrigeration. By adding different types of fins to the internal or external surface of a base bare tube, the heat transfer area is significantly increased, leading to a substantial enhancement in heat exchange efficiency. Particularly in gas-liquid heat exchange scenarios, finned tubes effectively balance the difference in…

Shanghai T.S. Industrial Co.,Ltd focuses on Finned Tubes, Tube Sheets and Heat E …

Shanghai T.S. Industrial Co., Ltd is a leading company specializing in Finned tubes, U bend tubes, and Tube sheets used in Heat Exchangers, Boiler Economizers, Coolers, and Heaters. We focus on supplying custom fin tubes, finned pipes, and tube sheets in various material configurations that enhance heat transfer rates and reduce operating costs.

T.S. Industrial Key Products Details:

1. Finned Tube

Finned tubes are composed of fins and base tubes. As heat exchange…

More Releases for Type

Pressure Pumping Market 2028 By Type, Well Type, Resource Type and Geography

The Insight Partners delivers well-researched industry-wide information on the Pressure Pumping market. It provides information on the market's essential aspects such as top participants, factors driving Pressure Pumping market growth, precise estimation of the Pressure Pumping market size, upcoming trends, changes in consumer behavioral pattern, market's competitive landscape, key market vendors, and other market features to gain an in-depth analysis of the market. Additionally, the report is a compilation of…

Lawn Mowers Market Analysis By Type, End User, Product Type, Fuel Type, Engine P …

Lawn Mowers Market Analysis By Type(Manual, Electric, Petrol, Robotic), By End User(Residential, Commercial), By Product Type(Walk behind Movers, Ride on Movers, Stand on Movers), By Fuel Type(Gas Powered, Propane Powered), By Engine Power(Less than 15 hp, Between 15hp and 30 hp, More than 30 hp), By Blade Type(Cylinder, Standard, Mulching, Lifting), By Drive Type(AWD, FWD, RWD), By Application(Residential, Professional landscaping, Golf Course, Government), By Distribution Channel(Retail Store, Online Website) &…

Automotive Exhaust System Component Market Type, Fuel Type, Treatment Device, Ve …

Automotive Exhaust System Component Market

This report focuses on top manufacturers in global market, Involved the assessment of Sales, price, revenue and market share for each manufacturer, covering

Tenneco

Faurecia

Eberspacher

Boysen

Sango

HITER

Yutaka Giken

Calsonic Kansei

Magneti Marelli

Benteler

Sejong Industrial

Katcon

Futaba

Wanxiang

Bosal

Harbin Airui

Dinex

Catar

DSM

Get Sample PDF including full TOC, Tables and Figures @ https://www.ozonemarketreports.com/automotive-and-transportation/global-automotive-exhaust-system-components-market-professional-survey-report-2019/59563

On the basis of product, this report displays the Sales, revenue, price, market share and growth rate of each type, primarily split into

Exhaust Manifold

Exhaust Pipe

Catalytic Converter

Exhaust Temperature Sensor

Car Muffler

Exhaust…

Uterine Manipulator Devices Market Report 2018: Segmentation by Type (Donnez Typ …

Global Uterine Manipulator Devices market research report provides company profile for ConMed, Richard Wolf, Bisinger, Planmeca Oy, Ethicon Endosurgery, Cooper Surgical, Hospiiniz International, C. R. Bard and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025,…

Automotive Electric Vacuum Pump Market By Type Diaphragm Type, Swing Piston Type …

Automatic electric vacuum pump is a device that gets the drive from the camshaft in the engine. It can also be run by alternator shaft in some designs. It’s an added benefit to any engine, which has high performance. The primary function of an automatic electric vacuum pump is to drain out the air from brake booster tank hence creating the vacuum, which in turn can be used for application…

Marine Composites Market |By Type |Resin Type|Vessel Type|Fiber Type |Region Ana …

The report includes market segmentation by composites type (metal matrix composite, ceramic matrix composite, polymer matrix composite); polymer matrix composite by fiber type (glass fiber, carbon fiber, others); polymer matrix composite by resin type (polyester, vinyl ester, epoxy, thermoplastic, others); vessel type (power boats, sailboats, cruise ships, others); and region (North America, Europe, APAC, Latin America, MEA).

Download Latest Free PDF Sample Brochure of “Marine Composites Market” With Detailed TOC…