Press release

A Comprehensive Guide to Finned Tube Types |Heat Exchanger

Finned tubes are indispensable core components within heat exchangers across various sectors, including power engineering, chemical production, petroleum refining, air conditioning engineering, and refrigeration. By adding different types of fins to the internal or external surface of a base bare tube, the heat transfer area is significantly increased, leading to a substantial enhancement in heat exchange efficiency. Particularly in gas-liquid heat exchange scenarios, finned tubes effectively balance the difference in heat transfer coefficients between the gas side and the liquid side, making them a critical component for high-efficiency heat exchangers.The Three Core Functions of Finned Tubes:

• Heat Transfer Enhancement

• Balancing Heat Transfer Efficiency

• Improving Economy and Compactness

Finned tubes come in a diverse range of fin shapes and constructions, each designed with specific application scenarios and performance characteristics in mind.

These include:

• Crimped finned tube

• L/LL/KL/Perforated L Type finned tube

• Extruded solid/serrated finned tube

• Embedded G type finned tube

• Laser weld finned tube

• High frequency welded solid/serrated tube

• Square H/double HH finned tube

• Studded pipe

• Longitudinal finned tube

• Brazed/hot-dipped galvanized elliptical finned tube

• Low fin tube

• Cast iron square finned tube

• Brazed single row flat finned tube

• Furnace wall panel fin tube

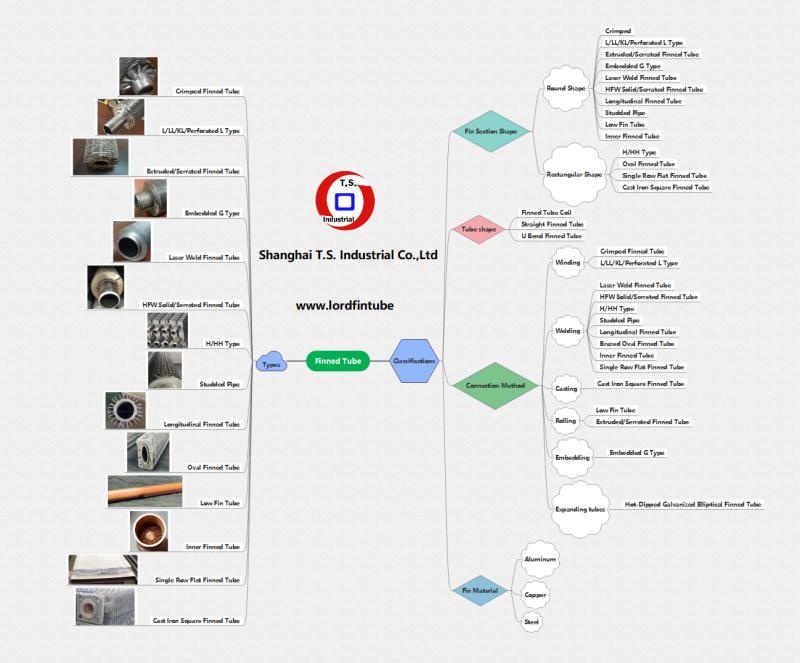

Finned Tube Classification

1. By Fin Cross-Sectional Shape

1Circular Shape

• Crimped

• L/LL/KL/Perforated L Type

• Extruded/Serrated Finned Tube

• Embedded G Type

• Laser Weld Finned Tube

• HFW Solid/Serrated Finned Tube

• Longitudinal Finned Tube

• Studded Pipe

• Low Fin Tube

• Inner Finned Tube

• H/HH Type

2Rectangular Shape

• Oval Finned Tube

• Single Row Flat Finned Tube

• Cast Iron Square Finned Tube

2. By Tube Shape/Configuration

1Finned Tube Coil

A finned tube coil is formed by bending a finned tube into a coiled configuration. Compared to straight finned tubes, it offers a more compact design, saving significant space.

2Straight Finned Tube

3U Bend Finned Tube

The structure of the U-bend finned tube is unique. A continuous metal tube is bent into a 180-degree U-shape, resulting in two parallel straight sections connected by a curved return bend. Fins are then added to the external surface of the straight sections.

3. By Manufacturing Process

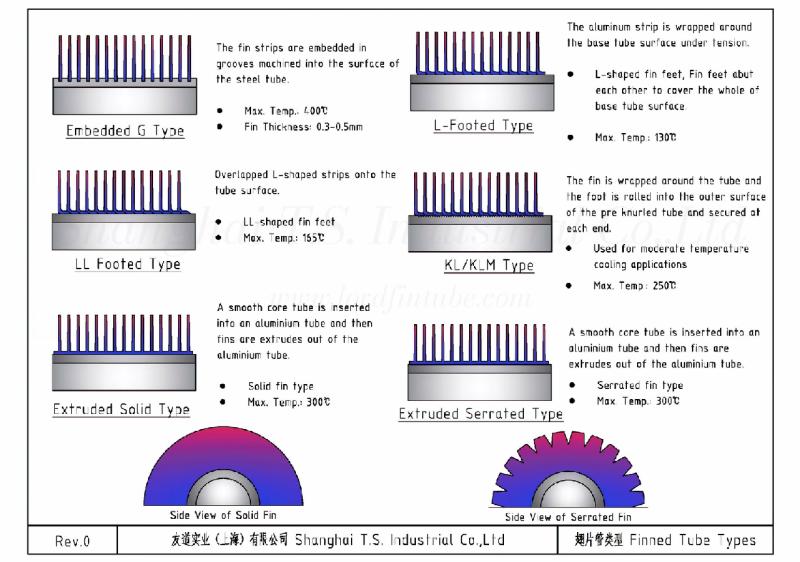

1By Winding

Process: Metal strip (typically aluminum or copper) is spirally wound onto the exterior surface of a base tube (typically steel, copper, or stainless steel) under specific tension using specialized winding equipment, forming a helical fin structure.

Features: Cost-effective manufacturing.

• Crimped Finned Tube

• L/LL/KL/Perforated L Type

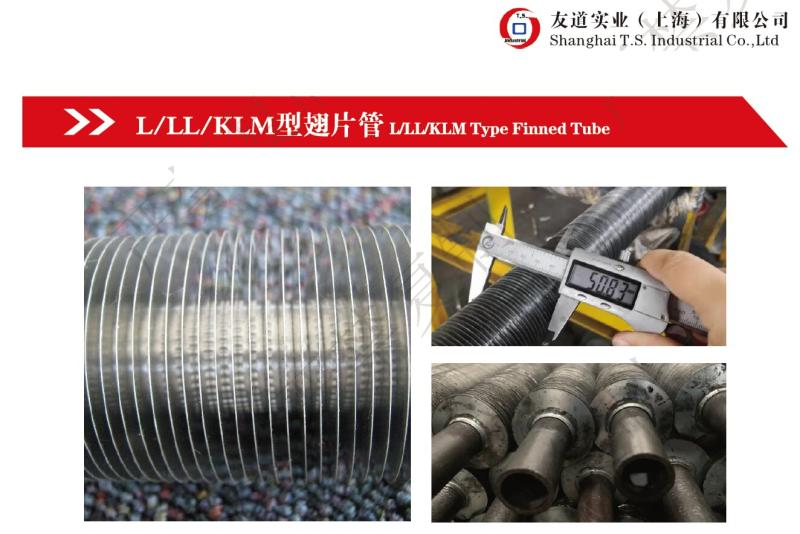

The primary difference between L, LL, and KL types lies in the method of securing the fin root to the base tube.

2By Welding

Process: This type permanently bonds the fins to the base tube via a welding process. The core principle involves replacing mechanical tension bonds with a metallurgical bond, which eliminates contact thermal resistance and achieves superior heat transfer performance and structural integrity.

Features: High strength and excellent heat transfer due to metallurgical bonding.

• Laser weld Finned tube https://www.lordfintube.com/laser-welded-carbon-steel-finned-tube_1290.html

• Square H/Rectangular HH finned tube https://www.lordfintube.com/double-s-type-fin-tube_1162.html

• Studded pipe https://www.lordfintube.com/studded-tubes_1163.html

• Longitudinal finned tube

• Inner finned tube

• Brazed elliptical finned tube

• Single row plat finned tube

Among various welding processes, high-frequency resistance welding (HFW) is the most widely used manufacturing method. HFW finned tubes can be further divided into solid fin and serrated fin types:

• HFW solid finned tube

• HFW serrated finned tube

4By Casting

Process: Cast square finned tubes utilize an integral casting process where the fins and the tube body form a seamless whole.

This fundamentally prevents any form of "crevice corrosion" and "contact thermal resistance," ensuring optimal corrosion resistance and long-term structural integrity.

5By Rolling

Process: This process uses specialized rolling mills to extrude fins directly from the external metal of a bare tube via roll-forming.

The rolling process can produce fins that are thicker at the root and thinner at the tip. This shape better conforms to heat conduction principles (higher heat flux density at the root), further optimizing heat transfer efficiency while ensuring mechanical strength at the fin root.

• Extruded finned tube

• Extruded serrated finned tube

• Low fin tube

6 By Expanding Tubes

Process: This process is typically used specifically for hot-dipped galvanized elliptical finned tubes. First, the fins are slipped onto the oval base tube. Then, a tube expansion process is used to mechanically fix the fins to the tube surface. Finally, the assembly undergoes hot-dip galvanizing.

4. By Fin Material

1Aluminum Fins: Lightweight, high thermal conductivity.

• Extruded/serrated finned tube

• Crimped finned tube

• L/LL/KL/Perforated L Type

• Embedded G Type finned tube

• Single row flat finned tube

• Oval finned tube

2Copper Fins: Excellent thermal conductivity and corrosion resistance.

• Extruded finned tube

• Crimped finned tube

• L/LL/KL/Perforated L Type

• Embedded G Type finned tube https://www.lordfintube.com/copper-embedded-finned-tube_1335.html

• Laser weld finned tube

• Longitudinal finned tube

• Inner finned tube

• Low fin tube

3Steel Fins: High strength, high-temperature resistance.

• Laser weld finned tube

• HFW solid/serrated finned tube

• H/HH type

• Studded pipe

• Longitudinal finned tube

• Oval finned tube

• Inner finned tube

• Low fin tube

• Cast Iron Square Finned Tube

Company Name: Shanghai T.S. Industrial Co. Ltd

Contact Name: Miss Estela

Address: No.2, Lane 1588 Youyi Road, Baoshan, Shanghai, The P. R. of China. Post. 201999

Email: estela@lordfintube.com

Website: https://www.lordfintube.com/

Shanghai T.S. Industrial Co., Ltd is a leading company specializing in Finned tubes, U bend tubes, and Tube sheets used in Heat Exchangers, Boiler Economizers, Coolers, and Heaters. We focus on supplying custom fin tubes, finned pipes, and tube sheets in various material configurations that enhance heat transfer rates and reduce operating costs.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Comprehensive Guide to Finned Tube Types |Heat Exchanger here

News-ID: 4193190 • Views: …

More Releases from Shanghai T.S. Industrial Co.,Ltd

Do you know the most cost-efficiency bimetallic finned tube?

As a key heat transfer element, the finned tube's core function lies in balancing the difference in heat transfer coefficients between the two fluid sides of a heat exchanger. By installing fins on the side with a lower heat transfer coefficient, the heat transfer area is enlarged. It is indispensable in applications requiring enhanced heat transfer, such as boiler economizers and air coolers.

In industrial sectors like power, chemical, petrochemical, air…

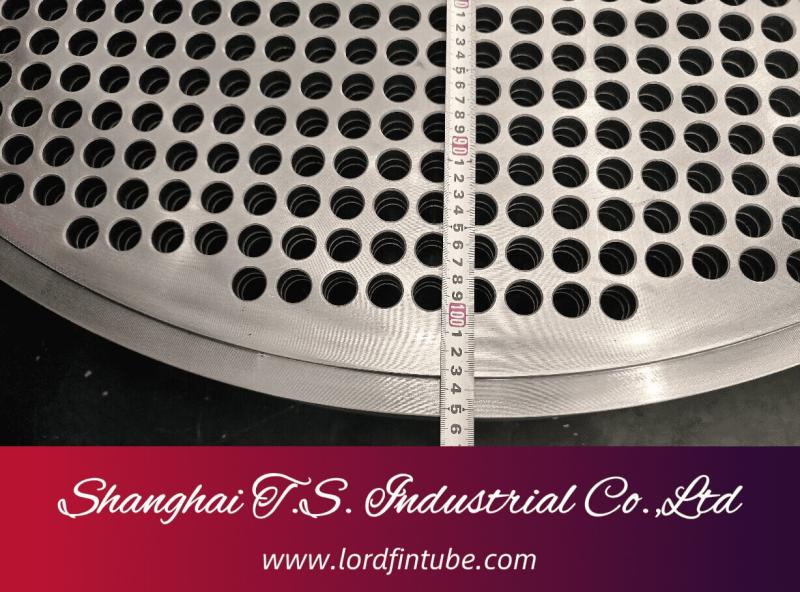

Lordfintube--Tubesheet for Shell and Tube Heat Exchanger

Within the complex internal structure of a shell and tube heat exchanger, the tube sheet plays a pivotal role-it is not only the supporting skeleton for the tube bundle but also the critical barrier separating the tube-side and shell-side media. A well-designed and precisely manufactured tube sheet directly determines the efficiency, safety, and service life of the heat exchanger. As a professional manufacturer of heat exchanger tube sheets and baffles,…

What's the Difference between L/LL/KL Type Finned Tube?

In an era where energy efficiency is increasingly vital to industrial operations, even minor performance improvements in heat exchangers-the core equipment for thermal energy recovery and management-can translate into significant operational cost savings. At the heart of most heat exchangers lies the finned tube, whose type selection directly dictates the entire system's efficiency, service life, and reliability. This article provides an in-depth analysis of three widely used finned tube types:…

Shanghai T.S. Industrial Co.,Ltd focuses on Finned Tubes, Tube Sheets and Heat E …

Shanghai T.S. Industrial Co., Ltd is a leading company specializing in Finned tubes, U bend tubes, and Tube sheets used in Heat Exchangers, Boiler Economizers, Coolers, and Heaters. We focus on supplying custom fin tubes, finned pipes, and tube sheets in various material configurations that enhance heat transfer rates and reduce operating costs.

T.S. Industrial Key Products Details:

1. Finned Tube

Finned tubes are composed of fins and base tubes. As heat exchange…

More Releases for Fin

Fintelligence (Fin-telligence.com) Reviews Silver Prices

In this article, Fintelligence reviews the surge in silver prices, highlighting how industrial demand and supply constraints have contributed to the metal's record high.

As silver prices continue to rise, traders, especially those in the Netherlands, are closely monitoring these developments.

The current market conditions offer potential opportunities, but a thorough understanding of the key factors driving silver's growth is essential for anyone looking to invest or trade in this…

Fin Types for Aluminum Plate Fin Heat Exchangers

1: Definition of Aluminum Fins [https://www.coolerchina.com/]

Fins are the most basic components of plate-fin heat exchangers. The heat transfer process is mainly completed by fins, and only a part is completed directly by the partition.

The connection between the fins and the partition is perfect brazing, so most of the heat is transferred to the cold carrier through the fins and the partition.

Since the heat transfer of the fins [https://www.coolerchina.com/] is not…

Fin Fish Market Size 2024 to 2031.

Market Overview and Report Coverage

The Fin Fish Market refers to the global market for various species of edible fish, including tuna, salmon, cod, and tilapia. The market is driven by factors such as increasing consumer awareness regarding the health benefits of fish consumption, rising demand for protein-rich food, and a growing population with disposable income.

The future outlook of the Fin Fish Market looks promising, with a projected compound…

Fin Fish Market Prolific Business Methodology and Techniques and Revenue | Cooke …

Fin Fish Market size reached US$ 186.1 Billion in 2022. Looking forward, the market to reach US$ 242.4 Billion by 2028, exhibiting a growth rate (CAGR) of 4.3% during 2023-2028. Feeding, production, regular stocking, and conservation of aquatic life are all part of the production and fishing of fin fish. Freshwater, brackish, and marine waters are the three environments in which fin fish are raised. In addition, freshwater aquaculture is…

Fin Fish Market Progresses for Huge Profits by 2027 : Marine Harvest ASA, P/F Ba …

Major players in the industry have adopted strategies such as acquisition, partnership & agreement, merger, and geographical expansion, to expand their market share and increase profitability. The key player in the market include Cermaq Group AS (Mitsubishi Corporation), Cooke Fin fish Inc., Grupo Farallon Fin fish, Leroy Sea Food Group, Marine Harvest ASA, P/F Bakkafrost, Selonda Fin fish S.A., Stolt Sea Farm, Tassal Group Limited, and Thai Union Group Public…

High Frequency Welded Fin Tubes market: New Prospects to Emerge by 2028 | Delfin …

"The global High Frequency Welded Fin Tubes Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global High Frequency Welded Fin Tubes Market. For instance, the market dynamics section digs deep into the drivers, restraints,…