Press release

The Global AI in Manufacturing Execution System Market is projected to reach a market size of USD 9.09 billion by 2030

According to the report published by Virtue Market Research in 2024, the Global AI in Manufacturing Execution System Market was valued at USD 4.91 billion and is projected to reach a market size of USD 9.09 billion by 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 10.8%.Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/ai-manufacturing-execution-system-market/request-sample

The AI in Manufacturing Execution System (MES) market is experiencing significant growth, driven by advancements in technology and changing industry needs. One of the primary long-term drivers of this market is the increasing demand for real-time production visibility and process optimization. Manufacturers are seeking ways to enhance efficiency, reduce downtime, and improve product quality. AI-powered MES solutions offer predictive analytics, enabling proactive maintenance and minimizing unplanned disruptions. This shift towards data-driven decision-making is transforming traditional manufacturing processes into more agile and responsive systems.

The COVID-19 pandemic had a profound impact on the manufacturing sector, highlighting vulnerabilities in supply chains and production processes. During the crisis, many manufacturers faced disruptions that underscored the need for greater operational resilience and agility. In response, there was a significant acceleration in the adoption of digital technologies, including AI, to enhance operational efficiency and flexibility. The pandemic acted as a catalyst, prompting manufacturers to invest in AI-powered MES solutions to better navigate future uncertainties and ensure continuity in operations.

In the short term, one of the key drivers of the AI in MES market is the need for improved quality control and defect detection. Manufacturers are increasingly turning to AI-powered image analysis and machine learning algorithms to monitor product quality in real-time. These technologies can detect defects early in the production process, reducing waste and ensuring that only high-quality products reach the market. This approach not only enhances product quality but also contributes to cost savings and customer satisfaction.

An emerging opportunity within the industry is the integration of AI with the Industrial Internet of Things (IIoT). The convergence of AI and IIoT allows for the collection and analysis of vast amounts of data from connected devices on the shop floor. This integration enables manufacturers to gain deeper insights into their operations, leading to more informed decision-making and optimized production processes. As IIoT adoption continues to rise, the synergy between AI and IIoT is expected to unlock new avenues for innovation and efficiency in manufacturing.

A notable trend in the AI in MES market is the increasing focus on sustainability and resource optimization. Manufacturers are leveraging AI to reduce energy consumption, minimize waste, and optimize resource utilization. AI algorithms can analyze production data to identify areas where resources are being underutilized or where energy consumption can be reduced. By implementing AI-driven solutions, manufacturers are not only improving their bottom line but also contributing to environmental sustainability efforts. This trend reflects a broader industry shift towards more responsible and efficient manufacturing practices.

Segmentation Analysis:

By Component: Software, Services

AI in Manufacturing Execution System market by component is growing as companies look to enhance production and reduce mistakes. Software solutions are the largest in this segment because they help manufacturers plan, monitor, and control production processes in real time. These platforms offer dashboards, analytics, and scheduling tools that make factory operations smoother. Meanwhile, services are the fastest growing during the forecast period. Services include consulting, integration, and maintenance support for AI-based MES solutions. Many manufacturers are seeking expert help to install, customize, and update their systems so that they fit specific production needs.

This growth is also fueled by the increasing adoption of remote support and digital training, which makes it easier for companies to use AI in their processes without needing to hire large in-house teams. The combination of software and specialized services ensures that factories can improve efficiency, reduce errors, and respond quickly to production challenges. By investing in both software and services, manufacturers can make their operations smarter and more responsive, while also adapting to changing market demands faster than before.

By Deployment: On-Premises, Cloud, Hybrid

AI in Manufacturing Execution System market by deployment is evolving as factories explore ways to manage data efficiently and securely. On-premises deployment is the largest in this segment because it gives companies complete control over their production data and systems. Many traditional manufacturers prefer on-premises solutions to maintain security and meet regulatory requirements. On the other hand, hybrid deployment is the fastest growing during the forecast period. Hybrid systems combine the strengths of on-premises and cloud-based platforms, allowing manufacturers to store sensitive data locally while using cloud resources for analytics, updates, and collaboration.

This approach offers flexibility and scalability, which is attracting companies that want to optimize operations without completely shifting to the cloud. Hybrid deployment also enables factories to implement AI-driven monitoring and predictive maintenance across multiple sites. With hybrid solutions, manufacturers can gain insights from large amounts of data while keeping critical operations secure, making it an attractive choice for those looking to modernize production without compromising control.

Read More @ https://virtuemarketresearch.com/report/ai-manufacturing-execution-system-market

Regional Analysis:

AI in Manufacturing Execution System market by region is shaped by differences in technology adoption, manufacturing scale, and industrial policies. North America is the largest in this segment due to its advanced manufacturing infrastructure, strong investment in Industry 4.0 technologies, and high adoption of AI solutions across automotive, electronics, and aerospace industries. Factories in this region benefit from strong research ecosystems and skilled labor, which accelerates the use of AI in MES systems. Asia-Pacific is the fastest growing during the forecast period.

Rapid industrialization, increasing factory automation, and strong support from governments in countries like China, India, and Japan are driving growth. Many manufacturers are adopting AI-powered MES to improve productivity, reduce downtime, and optimize resources in large-scale factories. Europe, South America, and the Middle East & Africa also contribute to growth, but at a slower pace due to varying levels of digital transformation and investment in AI. The regional differences highlight how adoption depends on infrastructure, labor skills, and market priorities, making North America a mature leader and Asia-Pacific a fast-growing hub for AI in manufacturing.

Latest Industry Developments:

• Strategic Partnerships to Expand AI Capabilities: Companies in the AI in Manufacturing Execution System market are forming strategic partnerships to enhance their AI capabilities and broaden their market reach. By collaborating with technology providers, research institutions, and industry leaders, these companies can integrate advanced AI algorithms, leverage specialized expertise, and access new customer bases. These partnerships enable the development of more robust and innovative AI-powered MES solutions, positioning companies to meet the evolving demands of the manufacturing sector and gain a competitive edge in the market.

• Adoption of Edge Computing for Real-Time Processing: To improve the responsiveness and efficiency of their MES solutions, companies are increasingly adopting edge computing technologies. By processing data closer to the source, such as on the factory floor, manufacturers can achieve real-time analytics, reduce latency, and enhance decision-making capabilities. This approach allows for quicker identification of issues, more agile production adjustments, and overall improved operational performance, thereby strengthening the market position of companies that implement edge computing in their AI-driven MES systems.

• Investment in Generative AI for Predictive Analytics: Investing in generative AI technologies is becoming a key trend among companies aiming to enhance their MES offerings. Generative AI enables the creation of advanced predictive models that can forecast potential production disruptions, optimize maintenance schedules, and improve resource allocation. By incorporating these capabilities, companies can offer more proactive and intelligent MES solutions, leading to increased operational efficiency and a stronger market presence in the competitive AI in MES landscape.

customize the Full Report Based on Your Requirements @ https://virtuemarketresearch.com/report/ai-manufacturing-execution-system-market/customization

contact Us:

Virtue Market Research

Kumar Plaza, #103, SRPF Rd, Ramtekadi, Pune, Maharashtra 411013, India

About Us:

"Virtue Market Research stands at the forefront of strategic analysis, empowering businesses to navigate complex market landscapes with precision and confidence. Specializing in both syndicated and bespoke consulting services, we offer in-depth insights into the ever-evolving interplay between global demand and supply dynamics. Leveraging our expertise, businesses can identify emerging opportunities, discern critical trends, and make decisions that pave the way for future success."

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Global AI in Manufacturing Execution System Market is projected to reach a market size of USD 9.09 billion by 2030 here

News-ID: 4306732 • Views: …

More Releases from Virtue Market Research

The Global Vodka Seltzer Market is projected to reach a market size of USD 16.22 …

The Vodka Seltzer Market was valued at USD 9.4 billion in 2024 and is projected to reach a market size of USD 16.21 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.1%.

Request Sample @ https://virtuemarketresearch.com/report/vodka-seltzer-market/request-sample

The vodka seltzer market has grown from a niche beverage choice into a mainstream favorite, supported by shifting consumer lifestyles and evolving…

The Global Telehealth Services Market and is projected to reach a market size of …

The Global Telehealth Services Market was valued at USD 126.1 billion and is projected to reach a market size of USD 302.49 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 15.7%.

Request Sample @ https://virtuemarketresearch.com/report/telehealth-services-market/request-sample

The perennial shift towards patient-centric healthcare has been a pivotal long-term market driver for telehealth services. Over the years, the industry has witnessed…

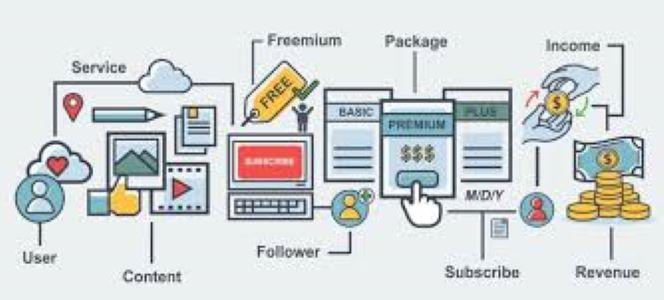

The Subscription Box/Subscription E-Commerce Market is projected to reach a mark …

The Subscription Box/Subscription E-Commerce Market is valued at USD 47.19 billion in 2024 and is projected to reach a market size of USD 97.73 billion by the end of 2030. Over the outlook period of 2025-2030, the market is anticipated to grow at a CAGR of 12.9%.

Request Sample @ https://virtuemarketresearch.com/report/subscription-e-commerce-market/request-sample

The subscription e-commerce market has grown into one of the most dynamic parts of the digital economy. It began as a…

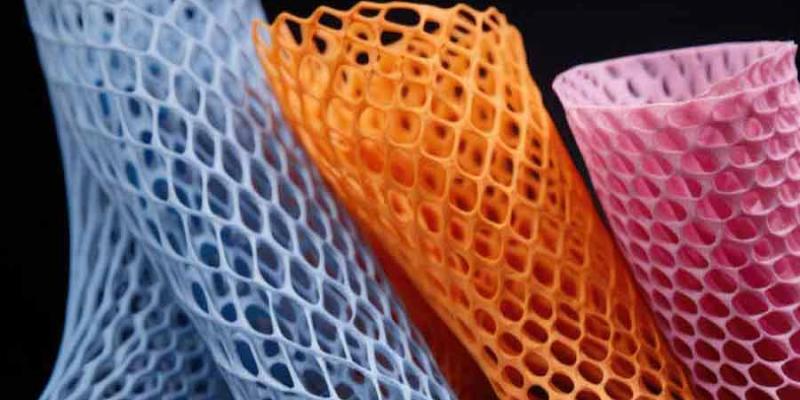

The Global Aramid Fibre Reinforced Polymer Composites Market is projected to rea …

According to the report published by Virtue Market Research in Aramid Fibre Reinforced Polymer Composites Market was valued at USD 5.55 billion and is projected to reach a market size of USD 8.57 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 7.5%.

Request Sample Copy of this Report @ https://virtuemarketresearch.com/report/aramid-fibre-reinforced-polymer-composites-market/request-sample

The Aramid Fibre Reinforced Polymer Composites…

More Releases for MES

PROXIA is ahead with MES!

In our fast-paced world, where progress and technology go hand in hand, engineering software solutions such as MES (Manufacturing Execution Systems) have long been indispensable. But which providers are setting new standards in terms of smooth production processes and efficient management of the entire product life cycle? As part of the "Professional User Rating: Engineering Solutions 2025", the research and analyst firm techconsult, a Heise Group company, examined the MES…

Manufacturing Execution System (MES) Market - The Popularity of Cloud-Based MES …

According to a new market report published by Transparency Market Research The global manufacturing execution system (MES) market is expected to reach a value of US$ 18,067.9 Mn by 2025 on account of the rising demand for improving productivity and executing complex production processes efficiently. The market is projected to expand at a CAGR of 11.2% during the forecast period from 2017 to 2025. The growth is attributed to growing…

Manufacturing Execution System (MES) Market - The Popularity of Cloud-Based MES …

According to a new market report published by Transparency Market Research The global manufacturing execution system (MES) market is expected to reach a value of US$ 18,067.9 Mn by 2025 on account of the rising demand for improving productivity and executing complex production processes efficiently. The market is projected to expand at a CAGR of 11.2% during the forecast period from 2017 to 2025. The growth is attributed to growing…

MES Joins SafeTRANS Network

Berlin (Germany), April 28, 2015: Model Engineering Solutions (MES), specialists in embedded software from Berlin, has become a member of the international competence network SafeTRANS. SafeTRANS is an association of prestigious enterprises and scientific institutions that ensures exchange between research and industry in embedded systems for transportation. The goal of the network is to increase the safety of transportation with the help of cutting-edge technology and optimized processes.

Focus of the…

MES: Expansion in Asia

Berlin, November 24, 2014: Model Engineering Solutions (MES), the Berlin-based specialist for model-based software development, has significantly expanded its business in Asia. In recent years, MES has built up a network of local partners in Japan, Korea, China, and India in order to benefit from the growing market and increasing interest in model-based development and ISO 26262 in Asia.

Asia: Driving force in the automotive industry

The automotive industry continues…

MES & Process Minds Europe 2013

Automation & Control - Improving Operational Excellence in Process Industry

Manufacturing operations by implementing Comprehensive & Compliant Data and Information Platform & Integrated IT systems|

30th September– 1th October 2013, Maritime ProArte Hotel Berlin, Germany

http://pharma-mes2013.we-conect.com/

"Very good and informative conference to share knowledge and to benchmark your company in your industry sector."

Kathrin Wilhelm, Fresenius Kabi D-GmbH

By popular demand, we.CONECT is bringing board-level attendees from manufacturing execution systems management from all over…