Press release

Foam Based Hydraulic Fracturing Fluids for Shale Gas Market to increase rapidly by 2025

Global energy resources are depleting at an alarming rate. Conversely, energy requirements of developing economies are increasing at a rapid pace. Global focus on energy replenishment has shifted toward natural gas which is an environmentally friendly energy resource and also available in abundance. Natural gas extraction through hydraulic fracturing is economically viable as well as a popular technology around the globe. The relative permeability of shale rocks is extremely low; hence it produces very less volume of natural gas. Special extraction technology such as hydraulic fracturing is required to induce permeability in these rocks to produce natural gas. Foam based hydraulic fracturing fluids is a novel technology employed in tight shale gas reservoirs for the economically viable production and enhancement of natural gas. An effective foam based hydraulic fracturing operation depends on the type of foam used, additives used in the foam, and sub-surface formation properties.View Report Preview: https://www.transparencymarketresearch.com/foam-based-hydraulic-fracturing-fluids-shale-gas-market.html

There are generally three types of foam based hydraulic fracturing fluids. Most commonly used foam based hydraulic fracturing fluid in shale gas reservoirs is water based foam. Water based foams constitute water with foaming surfactant and nitrogen or carbon-di-oxide gas. Water based foams are suitable for low pressure shale formations as the foam becomes unstable with increasing underground pressure. Other foam based hydraulic fluids are acid based foam and alcohol based foam. Acid based foams constitute mild acid with foaming surfactant and nitrogen gas while alcohol based foam consists of methanol with foaming surfactant and nitrogen gas. Both acid and alcohol based foam are applied in water sensitive shale reservoirs. Nitrogen based foams are mostly used in fracturing fluids as they have better pressure and temperature stability. Most of the technological experiments for foam based hydraulic fracturing fluids have been conducted in shale gas reservoirs in the U.S. and Canada; hence, it is still a novel technology for most of the other countries in the world.

Extraction of shale gas is still a challenge around the globe despite its huge reserves as the gas is trapped in highly impervious shale rock formations and needs extremely modern and precise fracturing technology to extract the gas economically. Natural gas is captured in shale formations either by adsorption or by getting trapped in small pores or fractures of the formation; hence it is important to know the properties of the shale formation before selecting the foam type for fracturing. A significant amount of natural gas is stored as an adsorbed gas in the shale formation while very few shale reservoirs have natural gas trapped in pores or fractures. Surfactants are used to provide stability to the foam and also provide better bonding between the two phases of gas and fluid. After the preparation of the foam, some amount of proppant is also added to it to keep the fracture open in the shale rock after fracturing is done. The type of surfactant also plays an important role in the stability and performance of the fracturing fluid. Typically, anionic or cationic surfactants are used in foam based hydraulic fluids according to the hydrophilic and hydrophobic property of the shale formation. Conventional water based hydraulic fracturing process involves the use of large quantities of water which results in high capital cost on water treatment. Water based fracturing also results in polluting of underground water reservoirs with harmful chemicals and heavy metals. On other hand, foam based hydraulic fracturing uses very less water as compared to the conventional water based fracturing process. Also, foam used in foam based hydraulic fracturing fluids can also be recovered back through the well after completion of the process. In addition, foam based hydraulic fluids reduces environmental damage to underground water aquifers and offers better transportation of proppant which makes them a superior choice for hydraulic fracturing in environmentally protected zones.

Increase in hydro-fracturing, technological advancements, growing popularity of natural gas in the global energy mix, and huge global shale gas reserves around the globe are major factors driving the foam based hydraulic fracturing fluids for the shale gas market. North America is the leading producer of shale gas in the world followed by Europe and Asia Pacific. China has the largest reserves of shale gas in Asia Pacific, followed by Argentina and Algeria. Growing environmental concerns regarding hydraulic fracturing, sluggish economic growth in Europe and Latin America, and increase in prices of surfactants and chemicals are the major restraints of the foam based hydraulic fracturing fluids for the shale gas market around the globe.

Key players operating in the global foam based hydraulic fracturing fluids for the shale gas market include Anadarko Petroleum, Chevron Corporation, Conoco Phillips, Exxon Mobil Corporation, Halliburton Corporation, Schlumberger, Emerge Energy Services LP, and U.S. Silica Holdings Inc. Safe fracturing, rise in global natural gas demand, and improvement in hydraulic fracturing technology are likely to drive the market for foam based hydraulic fracturing fluids. Huge global shale gas reserves and need for environmental safety across the globe provides immense potential for the growth of foam based hydraulic fracturing fluids for the shale gas market.

Request to view Sample Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=31808

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications

About Us

Transparency Market Research (TMR) is a market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. TMR's experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us

Transparency Market Research

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: http://www.transparencymarketresearch.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Foam Based Hydraulic Fracturing Fluids for Shale Gas Market to increase rapidly by 2025 here

News-ID: 972585 • Views: …

More Releases from Transparency Market Research

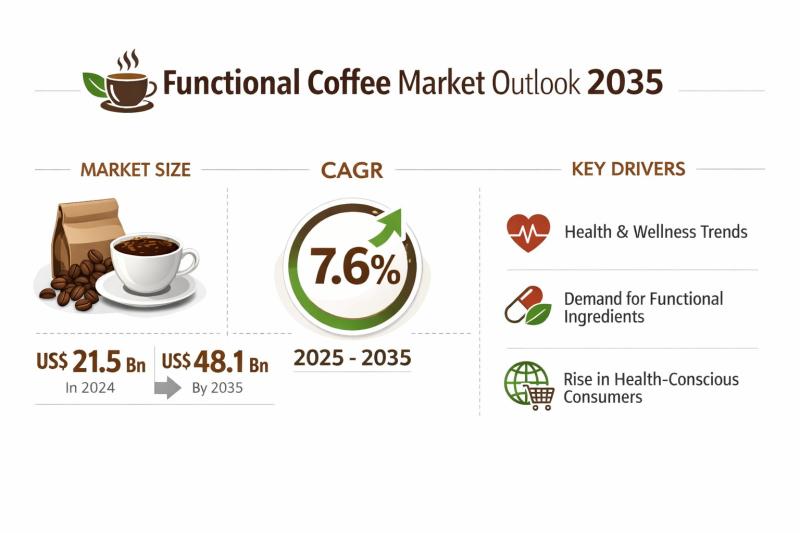

Functional Coffee Market Expanding at 7.6% CAGR Through 2035 - By Product Type / …

The global functional coffee market was valued at US$ 21.5 Bn in 2024 and is projected to reach US$ 48.1 Bn by 2035, expanding at a compound annual growth rate (CAGR) of 7.6% from 2025 to 2035. This steady growth trajectory reflects the strong convergence of coffee consumption habits with rising demand for functional and wellness-oriented beverages. Functional coffee has transitioned from a niche category to a mainstream product offering,…

Global Electric Face Cleanser Market Poised for Robust Growth, projected to Reac …

The global electric face cleanser market is witnessing a transformative growth phase as consumers increasingly integrate advanced skincare technologies into their daily routines. Valued at USD 9.8 billion in 2025, the market is projected to expand significantly and reach USD 23.6 billion by 2036, growing at a healthy compound annual growth rate (CAGR) of 8.6% from 2026 to 2036. This growth trajectory underscores the rising importance of personal care technology,…

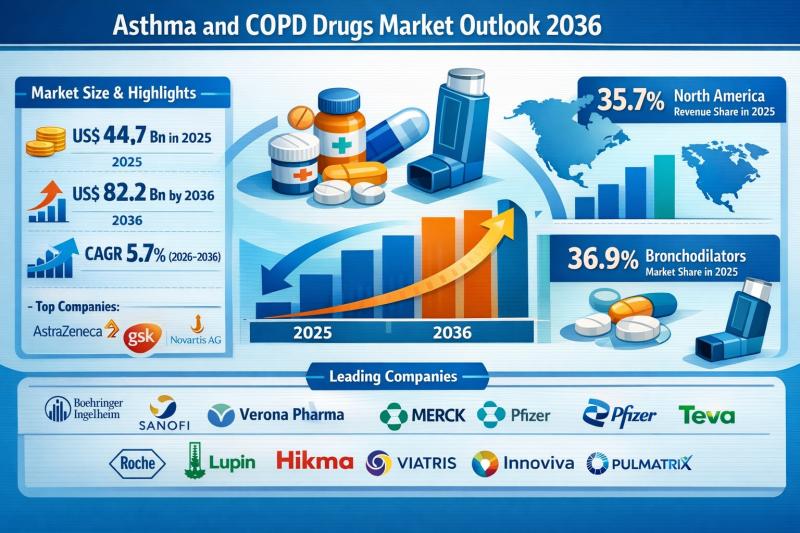

Asthma and COPD Drugs Market to Reach US$ 82.2 Billion by 2036, Growing at 5.7% …

The global asthma and COPD drugs market demonstrated strong fundamentals in 2025, with a valuation of US$ 44.7 Bn, reflecting the essential and recurring nature of respiratory therapeutics. Supported by a growing patient base and continuous pharmaceutical innovation, the market is projected to reach US$ 82.2 Bn by 2036, expanding at a compound annual growth rate (CAGR) of 5.7% from 2026 to 2036.

This growth trajectory highlights the increasing reliance on…

Low-Alcohol Beverages Market Outlook 2035: Global Industry Set to Expand from US …

The global low-alcohol beverages market is undergoing a structural transformation as consumers increasingly prioritize health, moderation, and mindful drinking without sacrificing taste or social experiences. Valued at US$ 2.1 billion in 2024, the market is projected to reach US$ 4.6 billion by 2035, expanding at a healthy CAGR of 7.5% from 2025 to 2035. This sustained growth reflects changing lifestyle preferences, generational shifts in alcohol consumption, and continuous innovation by…

More Releases for Foam

Foam Concentrate Market: High-growth Regions to Expand Geographic Footprint | Ch …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Foam Concentrate industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Foam Concentrate report, offering a meticulous…

Packaging Foams Market Report with Forecast 2020-2025 | Top Key Players: BASF, A …

Global Packaging Foams market would thus note a steady growth over the forecast period of 2020 - 2025. The robust CAGR (Compound Annual Rate Growth) will chart an upward growth curve and create lucrative growth opportunities in the global Packaging Foams market. In, turn, this will lead to improvement in market worth.

Request a PDF sample of this report: https://www.adroitmarketresearch.com/contacts/request-sample/1415

Global Packaging Foams Market: Notable Development

Global Packaging Foams market is set to…

Technical Foam Services Develops Innovative New Scaffold Foam

Northamptonshire, United Kingdom (8th February, 2013) - Technical Foam Services Ltd, a leading independent engineer-based manufacturer and foam producer, announces the creation of a new scaffold foam.

Technical Foam Services Ltd and their strategic construction partner have been working in unison to develop the Closed Cell PE Scaffold Foam, which uses high density polyethylene foam to offer protection against work equipment damage to decorated surfaces. The scaffold foam also uses a…

Technical Foam Services Creates Foam Inserts for Rak Ceramics

Northamptonshire, United Kingdom (18th February, 2013) - Technical Foam Services Ltd, a leading independent engineering-based manufacturer and foam producer, earlier this month secured a contract with leading ceramic tile design and manufacturer Rak Ceramics.

Rak Ceramics specialises in offering a range of high-quality ceramic tiles, distributing their products to DIY retailers and kitchen designers nationwide.

Sales representatives from the company were becoming increasingly concerned with the loss and damage of these tiles…

Technical Foam Services Manufactures Cancer Prevention Foam

Northamptonshire, United Kingdom (17 June, 2011) - Technical Foam Services, a leading independent engineering-based manufacturer and foam producer, is proud to have been part of an exciting new development in the world of cancer prevention.

A far cheaper and more patient-friendly method has been developed by the UK Medical Research Council, which involves the use of a reticulated foam sponge encapsulated within a pill. Once the pill is swallowed, it dissolves…

Technical Foam Services Expand Range of Foam Insert Fabrics

Northamptonshire, United Kingdom (19th May, 2011) – Technical Foam Services, a leading independent engineering-biased manufacturer and foam producer, has expanded their range of fabrics to be used with foam inserts.

Technical Foam Services have long been recognised as the UK’s leading supplier of foam inserts, producing them for a wide variety of applications, such as large suitcase inserts suitable for holding ceramics and glassware through to small inserts used…