Press release

A Beam of Innovative Light for 30 Years - Heraeus Noblelight Ltd. Celebrates Birthday

At the end of last year, Heraeus Noblelight Ltd celebrated a special company anniversary in Cambridge: 30 years of laser lamp production to the highest technical level. Reason enough to review the latest innovations and to look at current developments.When John and David Littlechild set up Noblelight Ltd near Cambridge in 1978, laser technology was then in its infancy and used mainly in research. The company began to produce laser excitation lamps and grew quickly, not least because of the triumphal march of lasers into the industrial arena. Already in the 1980s the company was distinguishing itself by its power of innovation. For example, it was closely involved in the development of the first “longlife” CW (continuous) laser lamp.

After its take-over by the precious metals- and technology company Heraeus in 1986, and the resulting access to advanced lamp manufacturing technology and highly developed quartz glass expertise, the innovation story of Heraeus Noblelight Ltd progressed even further. For example, in 2002, for the first time, a continuous laser lamp with an operating life of 500 hours was developed. In 2006, with the NextGen series, a flash lamp with a significantly increased operating life entered the market. Instead of the then current 500,000 million pulses, the operating life was increased to 3,000,000 million pulses under extreme conditions such as long pulse length and high power. Today, lasers, and hence laser lamps, are used in a wide range of applications: welding, cutting, marking and engraving. Lamp-pumped lasers are still an important technology because of their low investment costs, high output power, robustness and easy maintenance. Furthermore, xenon- and krypton lamps are now used in non-laser applications such as solar simulation and cosmetics.

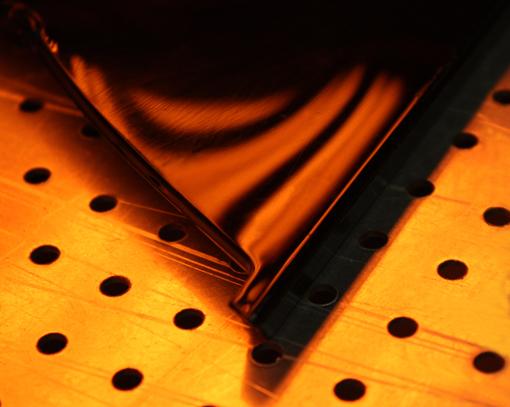

Customer-focused application development still pushes out the boundaries of laser performance. Recently, a well known Swiss laser manufacturer entrusted Heraeus with the development of a special laser excitation lamp. This was for a new precision laser for the very precise cutting of medical products such as stents. This new lamp had to work reliably under very difficult conditions with ultra-short pulses of less than 30 microseconds. Furthermore, the lamp had to have twice the operating life of a conventional lamp. To develop the new lamp, a German-British development from Heraeus worked intensively with the laboratory for lamp technology at the Kaiserlautern University of Applied Sciences. This University has been a collaborative partner of Heraeus Noblelight for many years. Using a high speed camera, the motion of the plasma in the lamp was precisely observed and analysed at 100 frames per second. As a result, the resonance effect in the plasma, for example, could be observed as it influences the output of the lamp at certain operating frequencies. By constructive modifications to the lamp, this resonance effect was eliminated so that the suitability of the lamp for very high frequencies was optimised.

Another current research project at the Kaiserlautern lamp laboratory for other lamp types relates to the investigation of electromagnetic compatibility. Especially for cosmetic IPL applications, RF noise (High frequency noise) can lead to certification problems for OEMs. Heraeus Noblelight and Kaiserlautern University are leaders in the development of lamps with very low RF noise levels.

Consistent Quality

A deciding factor in the stability of a laser is the constant high quality of the excitation lamp. Above all, the tolerance from lamp to lamp is an important aspect. Only when the range of variation is minimal, can the laser – and consequently the application – function reliably and accurately. In order to minimise lamp-specific tolerances, the manufacturing stages at Heraeus Noblelight are continuously optimised and automated. As a result, a very high and reproducible quality is achieved. Two examples: The hermetic connection between the quartz glass of the lamp body and the tungsten electrode is known as the “Seal”. The “Seal” must compensate for the different thermal expansion coefficients of quartz glass and tungsten. The stronger and more reliable the connection, the greater the lamp operating life. By automating the “Seal” process at Heraeus, the stability of the connection has been consistently improved and the quality and operating life of the laser lamps could be further increased.

In addition, Heraeus Noblelight Ltd has introduced a modern pump process for laser lamps. This allows a high purity of the noble gas in the lamp, minimises unwanted spectra and extends operating life. The automated production line is a world leader of its type and in the future, the company intends to invest more in its manufacturing processes to improve quality even further and reduce delivery times.

As the birthday cake was finally cut, John Littlechild, today working in the research and development team at Heraeus Noblelight Ltd., could be pleased – both with the way things have gone over the past few years and also with the way things are going in the future.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology- and market-leaders in the production of specialist light sources. In 2007, Heraeus Noblelight had an annual turnover of 90 Million € and employed 666 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, dental and medical products, quartz glass, and specialty lighting sources. With product revenues of € 3 billion and precious metal trading revenues of € 9 billion, as well as over 11,000 employees in more than 100 companies worldwide, Heraeus holds a leading position in its global markets.

Heraeus Noblelight GmbH

Mr. Thomas Lödel

Heraeusstraße 12-14

63450 Hanau, Germany

Phone +49 6181/35-8480

E-Mail: thomas.loedel@heraeus.com

www.heraeus-noblelight.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release A Beam of Innovative Light for 30 Years - Heraeus Noblelight Ltd. Celebrates Birthday here

News-ID: 71315 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

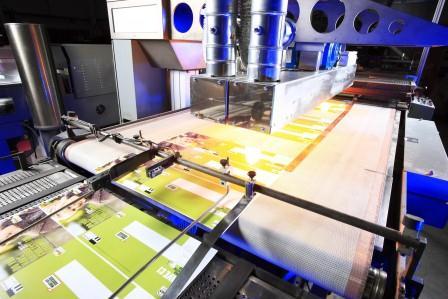

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Cathode

Cathode Active Material (CAM) Market Share Driven by EV Adoption and Cathode Che …

Cathode Active Material (CAM) Market

The global market for Cathode Active Material (CAM) was valued at US$ million in the year 2024 and is projected to reach a revised size of US$ million by 2031, growing at a CAGR of %during the forecast period.

View sample report

https://reports.valuates.com/request/sample/QYRE-Auto-38A19227/Global_Cathode_Active_Material_CAM_Market_Research_Report_2025

The Cathode Active Material (CAM) Market is expanding rapidly as electric mobility, renewable integration, and advanced consumer electronics increase reliance on high-performance lithium-ion batteries. Growing demand…

Electrolytic Copper Cathode Plate Market

LOS ANGELES, United States: The report is a fine example of comprehensive and accurate research study on the global Electrolytic Copper Cathode Plate market. It digs deep into critical aspects of the global Electrolytic Copper Cathode Plate market, including market dynamics, competition, regional advancement, and segmentation. It provides verified market figures such as CAGR, market share, revenue, volume, production, consumption, gross margin, and price. The global Electrolytic Copper Cathode Plate…

Cathode Active Materials Market Powering the Future: Sustainable and Innovative …

Cathode Active Materials Market to reach over USD 38.62 billion by the year 2031 - Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Cathode Active Materials Market Size, Share & Trends Analysis Report By Material Type (Lithium-Ion Cathode Materials, Lead-Acid Materials, And Other Materials), Battery Type (Lithium-Ion Batteries, Lead-Acid Batteries And Others)- Market Outlook And Industry Analysis 2031"

The global…

Lithium Ion Battery Cathode Material Market | Valuates Reports

The cathode material in the lithium-ion battery is the major component, which determines the energy density of the cell. This energy density is measured using cell voltage or cell capacity. The working mechanism of the lithium-ion battery is based on intercalation and deintercalation compounds, where the lithium ions from the cathode are introduced into the anode during the charging of the battery and extracted during discharge of the battery, with…

Cathode Materials Market Size, Share, Industry Overview 2023

The global cathode materials market size was valued at USD 24,234.8 million in 2022 and is poised to grow at a significant CAGR of 6.9% during the forecast period 2023-29. The primary drivers of the expansion of the global cathode materials market include the increasing demand for electric vehicles across the globe. Furthermore, the increasing demand for lithium-ion batteries in the renewable energy industry is expected to boost the growth…

Sputtering Equipment Cathode Market 2021 | Detailed Report

Sputtering Equipment Cathode Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Sputtering Equipment Cathode Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5016333

The report provides a comprehensive analysis of company profiles listed below:

- Kurt J. Lesker Company…