Press release

Specialty Light Sources for the Printing Industry

Hanau, February 2012The Competence in Specialty Light Sources for printing systems

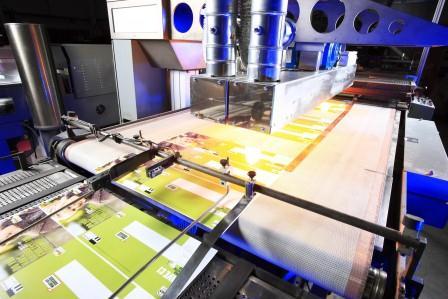

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its manufacturing competence in specialty light sources and systems for printing systems at Fespa 2012, in Barcelona, Spain. Learn more about infrared emitters, UV replacement lamps and systems and latest UV LED systems at Hall 3, stand N51.

Nowadays, people especially care about the usage of energy resources. That is why it is well worth the effort to examine industrial processes, to examine printing processes scrupulously and find techniques which offer the best results at the greatest possible economical and energy efficiency.

Infrared emitters improve energy efficiency

The Alito Color Group of Leyton, London achieved significant benefits through one simple change: They replaced their existing drier, which was fitted with near infrared (NIR), short wave emitters, with a Heraeus Carbon Infrared (CIR) System. Carbon Infrared (CIR) emitters from Heraeus Noblelight are especially efficient at drying water based inkjet inks. This is due to the medium wave infrared radiation, which the carbon emitters transfer into the inks at high power. Medium wave infrared radiation is absorbed extremely well by water-based inks. Carbon emitters combine high power and fast response times with the effective medium wavelengths.

Following successful tests, two carbon infrared (CIR) were fitted in the existing drier frame. Each 24kW module matches a special 4¼ inch print head. As a result, it is now possible to realise the complete capability of the high speed print heads. Practical usage has shown that the print quality can be maintained even at the high print speeds. In addition, the new emitters require less energy than before and have a significantly longer operating life. This has greatly improved the machine energy efficiency.

UV lamps and cartridges for efficient replacement

The emission spectrum of UV radiation is very important for the curing process. It must cause as many photons as possible to react with the coating, on one hand to cure the material completely and on the other to bind the coating with the substrate. Consequently, every curing process is complex and each coating system specifies its own individual curing parameters.

For theses individual processes Heraeus develops a variety of customized UV lamps and replacement lamps. This has been made possible through close collaboration with OEM partners, advances in lamp production have been best realized with the aid of intelligent energy supply.

A very efficient way to replace lamps at the end of life in digital printing machines is to replace the entire lamp cartridge. Using the used cartridge with just a new lamp is a false economy. The reflector degrades with temperature and becomes less efficient. It is also difficult to maintain the original shape after the old lamp has been removed. A well reshaped reflector could lose 15% of the ultraviolet radiation destined for the ink. So it is obvious that the lamp will need to be replaced again very soon. Second the system contains windows made of a high silica quartz glass. This material has to be kept clean. A small amount of material on these windows will absorb a considerable amount of energy that should be drying ink, not heating up the system. Heraeus Amba offers both replacement components: the complete cartridge solution and quartz glass plates, which allows the customer to replace the entire optical system in the print head of little more than the cost of a replacement lamp.

Customized UV LEDs for an efficient curing process

With digital printing, where the lamp, together with the print head, moves over the surface of the print, every little saving in weight and size matters. Innovative UV LEDs have a small shape and allow great flexibility in styling. According to customer specifications Heraeus Noblelight develops UV LED systems matching the machine environment. The individual system components are assembled from a modular construction system. Different sizes of UV LED moduls and wavelengths can be realized. A special integrated micro-optics technology enables the beam to be shaped to optimally suit the working distance required.

As a result, almost every special UV LED solution can be manufactured.

The system package also includes all the associated peripheral components such as cooling, control and power supply.

An important factor governing the operating life of a UV LED is the fact that all components belonging to the system are harmonically matched to each other. With the usage of UV LEDs, energy is saved during the curing process, because LEDs instantly switch on and off. So energy is consumed only on demand, when it is needed, without impairment of the performance of the LEDs.

Heraeus Noblelight manufactures UV-LED modules and systems in a complete development and production line. LED chips are processed in so-called “chip-on-board” technology and measured and tested in our in-house, accredited measurement laboratory. As a result, customer-specific system solutions can be assembled for an efficient curing process.

Heraeus Noblelight GmbH with its registered office in Hanau and subsidiaries in the U.S., Great Britain, France, China and Australia is one of the world's market and technology leaders in the field of special light source production. In 2010, Heraeus Noblelight's annual turnover was €98.9 million and the company employed 689 staff world-wide. Heraeus Noblelight develops, manufactures and sells infrared and ultraviolet emitters for use in research, the manufacturing, environmental, medical and cosmetics industries and analytical laboratories.

Heraeus Noblelight GmbH

Heraeusstr. 12 - 14

D-63450 Hanau

Press: Juliane Henze

juliane.henze@heraeus.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Specialty Light Sources for the Printing Industry here

News-ID: 211667 • Views: …

More Releases from Heraeus Noblelight

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

PID for Selective BTEX Determination

• Determining BTEX VOCs with a 10.0 eV PID lamp

• Heraeus PID lamps: high quality pure spectrum and long life

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources, launches the latest development in its Photoionisation Detector Lamps (PID) range: a 10.0 eV PID lamp which offers increased detection sensitivity in BTEX determination.

“A CaF2 filter is attached onto our standard 10.6…

More Releases for LED

HSC LED Successfully Delivers Taxi LED Displays to Moldova

HSC LED [https://www.hscled.com/] is pleased to announce the successful completion of a major project involving the delivery of taxi LED displays to Moldova. This achievement underscores our dedication to providing high-quality, innovative LED display solutions to global markets.

Image: https://www.abnewswire.com/upload/2025/03/c632e02b61fa3f45fb036d4012a026b5.jpg

This project involved the production and deployment of state-of-the-art taxi top LED displays, designed for high visibility, durability, and intelligent operation. Equipped with high brightness levels, waterproof protection, and efficient heat dissipation,…

Enhancing LED Lighting: What is a reflective LED light?

Nowadays, LED lights [https://www.cnblight.com/products/] have become the mainstream of lighting. There is an interesting question, why do LED lights in homes nowadays, whether they are desk lamps, pendant lamps, ceiling lamps, etc., often need to add a lamp shell? You should know that LED lights emit solid light, unlike traditional lamps such as incandescent lamps and fluorescent lamps, which require a lamp shell on the outside.

There are many reasons that…

Global Backlight LED Market| Global Backlight LED Industry | Backlight LED Marke …

The backlight LED market comprises of sales of Backlight LED & related services. LED backlight is a flat panel display that uses LED backlighting instead of cold cathode fluorescent (CCFL) backlighting. LED backlight displays also use thin-film-transistor liquid-crystal display (TFT LCD) technologies that offer better contrast and brightness, reduced energy consumption, greater color range more quick response to changes in the scene, and photorefractive effects. These displays are small chips…

Global LED Packaging Market Size Detail Analysis focusing Market Segmentation li …

Global LED Packaging Market Size Detail Analysis focusing Market Segmentation like Lamp-LED, Side-LED, TOP-LED, High-Power LED, SMD-LED, and Flip-Chip LED & more

The LED market is one of the quickly growing segments as they are replacing the traditional lighting equipment like bulbs due to their high efficiency and power saving capability. The LED packaging industry is also growing with innovations along with the LED industry as new technologies are being included…

Global LED Driver (LED Lighting Driver) Market Research Report

This report studies the global LED Driver (LED Lighting Driver) market status and forecast, categorizes the global LED Driver (LED Lighting Driver) market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in United States, Europe, China, Japan, South Korea and Taiwan and other regions.

Get sample copy of the report:

https://www.marketdensity.com/contact?ref=Sample&reportid=68754

Table of Contents:

Table of Contents

Global LED Driver (LED Lighting Driver) Market Research Report…

LED Driver And Chipset Market - Tax Exemptions For LED Technology Encourage Use …

Transparency Market Research, in a report titled “LED Driver and Chipset Market - Global Industry Analysis, Trend, Size, Share and Forecast 2015 - 2021,” states that the global LED driver and chipset market is projected to expand at a remarkable CAGR of 23.20% during the forecast period. The report states that the outstanding growth of the overall LED market in recent times will push the value of the LED driver…