Press release

Digitize Packaging: Bizerba at the PPMA Show 2017

Across a three-stand layout, Bizerba introduces solutions around the topics of digital transformation, food safety, batch size, logistics and labels at this year’s PPMA Show. Current trends including industry 4.0, Internet of Things, predictive maintenance, the interaction of multiple systems as well as availability and service are all part of Bizerba’s solution portfolio.Stand G10 – Convenience

CWE Combination Unit – demonstrating our fully integrated metal detector this device is to full higher-level M&S specification. With the addition of Brain2 FPV, Capture and Safety service, it demonstrates the full potential of high-speed checkweighing from Bizerba. The integrated metal detector boasts high detection accuracy with reliability.

BVS-L – An introductory inspection device from Bizerba with the ability to check fixed data on pre-printed films, and dynamically applied labels on both top and bottom of your pack. Checking everything from the position of the label, use by dates and readability of barcodes along with a multitude of additional checks. Connected to our Brain2 software the statistics and images of each inspected package are collated for future reporting.

Bizerba OCM Stand – Designed for integration at the end of your production line with multiple options available for additional equipment to be added at any time. Displayed on this stand we have our standard weighing platform connected to a GT12C touch screen display and our GLP80 labeller installed in an enclosure. Also attached is a barcode scanner for PLU selection from the retail packages.

X-Ray – The latest presentation for 2017 in our inspection range of equipment. Built to the higher-level M&S code of practice. Main features of this latest design is the ease of maintenance with belt changes and cleaning. Connected to the Bizerba dynamic devices offering automatic program change to allow a single point of product entry. This device is also connected to the Bizerba brain software displaying inspected products. Rejected items and the machines audit history is also uploaded for analysis should it be required.

iS75 – Our newest industrial PC with its sleek lines and high durability for the industrial environment. This device is displaying the information being gathered from the devices shown on this stand.

Stand H20 – Fresh

GLM-I100V – Part of the Bizerba flagship range of high speed labelling systems, it is capable of achieving a top speed of 100 packages per minute and being fitted with a v-belt, which, due to its inclined position can easily transport and label round or odd-shaped products. With its connection to the Bizerba brain software reach package weight is instantly recorded and saved to allow trend analysis to be carried out. The addition of our statistics capture software removes the need to record batch statistics manually or have endless streams of printouts. As we move into more diverse production demands the efficiencies of your production line can be monitored with our OEE system allowing instant live visuals of the current line performance.

Themosecure L – introduced in 2015 to fully compliment the bizerba range of end of line inspection equipment this device ensures that each package exiting the factory is fully inspected for label data and seal integrity. Dynamic calculations allow for this device to be used on both fixed and catch weight products to verify that the correct data is printed and can be fully validated before it gets to your end customer. Reduction of product recalls and error packages is eliminated with this device. Again, with its connection to the Bizerba brain software records of rejected packages are retained with statistical information and images.

iS20 Hygienic Scale – IP69 rated, this scale is designed to remain within the production area during routine wash down. Its fully welded, round frame along with its fully open design prevents any trapping of product waste or bacteria. Displayed within an isolated chamber showing water being sprayed on this device for the duration of the PPMA show.

Bizerba/Niche recipe station – a collaboration of Bizerba hardware and Niche software to allow the preparation of manufacturing batches of bulk items to ensure multiple ingredients are all weighed or counted in the most accurate and efficient manner reducing errors in the preparation stage and continuity of the final product. Along with the control of bulk, stock items at the order intake the system is capable of managing stock levels ensuring the production plan can be fulfilled.

iS75 – Our newest industrial PC with its sleek lines and high durability for the industrial environment. This device is displaying the information being gathered from the devices shown on this stand.

Stand J30 – MECH & Logistics

Production Bench - showing three static scale options with differing weight indicators.

Recessed into the table is our economy platform, which is connected to our iS30 indicator head. This terminal is connected to the Brain suite of software and is running sample check. This will prompt quality checks of product from the operators who will then follow a sequence of check to ensure that the off-line sampling is completed and that the required statistics records are updated.

In the middle of the table is our economy compact scale with an iS10 indicator head. This device features an internal battery allowing it to be used in areas without a permanent power supply. At the end of the day, it can simply be plugged back into the mains to charge ready for the following day.

As displayed on our fresh stand our hygienic scale is bolted to the table ensuring that it is secure and with its open design can be cleaned as part of the production bench. This scale is mounted with our iS20 indicator and is again connected to the brain software capturing each weight from the scale for analysis.

Additionally, on this production bench you find the Bizerba Brain server. From here, we can programme every machine connected to it, we have full remote control of all devices via the Bizerba e-service. Label designs, reports, schedules and stock levels can all be controlled from this single server. With the user level management, it is possible to ensure that users can only enter data and not send it to machines without the approval of a second or more senior user.

Hygienic lift up platform – Integrated into the stand floor this device is easily lifted to allow access for cleaning. The integrated ramp simply lifts off to revel the lifting handle where a simple and lightweight mechanism allows the device to be lifted to the cleaning position. Fully IP69 rated this scale can withstand the harshest of cleaning environments. Connected to this we have our iS30 indicator and barcode scanner. The scanner triggers the capture of the pallet or box weight where the two are collated within the Brain software and then automatically output to a separate location for importing into your ERP system allowing the calculation of product yield or parcel tracking.

Filling System – Another new offering from Bizerba this semi-automatic filling system demonstrates the power of the Bizerba iS50 indicator terminal with its ability to connect multiple scales allowing multiple stations to be controlled from a single device. The integrated PLC allows each station to be independently controlled. With its ATEX rating this is a perfect device for hazardous liquid filling.

About Bizerba

Bizerba offers its customers in industry, trade and logistics a globally unique solutions portfolio of hardware and software around the central value “weight”. This portfolio includes products and solutions related to slicing, processing, weighing, cashing, checking, commissioning, and labelling. A wide range of services from consulting and service to labels and consumables complete the portfolio.

Since 1866 Bizerba has made a significant contribution to the developments in the area of weighing technology and today is represented in 120 countries. The customer base includes globally operating companies in trade and industry as well as retailers, bakeries and butcheries. With around 3,900 employees worldwide and with its headquarters in Balingen, Baden Wuerttemberg, Bizerba has been in the same family for five generations. Additional production facilities are located in Germany, Austria, Switzerland, Italy, France, Spain, China and USA. Bizerba also has a global network of sales and service locations.

Bizerba (UK) Ltd

2-4 Erica Road,

Stacey Bushes

Milton Keynes

Buckinghamshire

MK12 6HS

Anthony Matthews - Digital Marketing Manager

anthony.matthews@bizerba.com

https://www.bizerba.com/en_gb/home/

https://www.bizerba.com/en_gb/news/trade-shows/trade-shows.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Digitize Packaging: Bizerba at the PPMA Show 2017 here

News-ID: 699895 • Views: …

More Releases from Bizerba (UK) Ltd

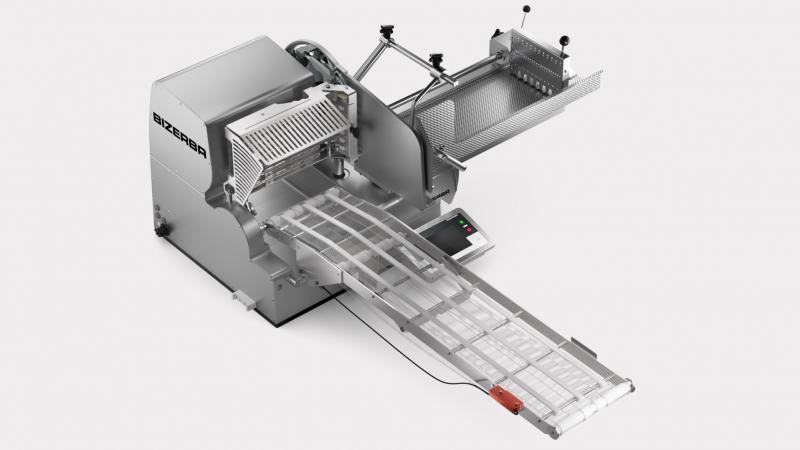

New Industrial Food Slicer

Newly released our much-anticipated Industrial Food Slicer. After many years of success with the predecessor to this new unit, the A400 has sadly come to the end of its life. We will of course continue to support the A400 Variants however we have created a new beast that is going to take the food production for the SME sector by storm.

The new VSI T Industrial food slicer is now available…

COMPANY GAINS GREEN GLORY

BIZERBA UK have won the BRONZE Environment Award in the national campaign to find the greenest individuals, companies, councils and communities.

They competed against more than 800 other nominations in the Green Apple Awards for Environmental Best Practice with their project, ENERGY EFFICIENT CUTTING.

They were presented with their trophy and certificate at a glittering presentation ceremony hosted by Liz Kendall MP at the Houses of Parliament on November 12th, 2018.

As…

Bizerba SliceCheck for Visual Inspections of Sliced Products

Bizerba‘s visual inspection system SliceCheck enables visual 100-percent inspections of sliced products before packaging. The real-time check detects mechanical damages and visual flaws including torn edges, holes or false orientation and rejects faulty products in time, thus saving material and cost.

SliceCheck enables visual 100-percent inspections of sliced products before packaging.

Following the slicing process, SliceCheck’s visual inspection technology checks the top slice of each product stack for criteria like shape,…

More Releases for PPMA

EMKA at PPMA Exhibition, 1st – 3rd October 2019 at the NEC, Stand No. G96

EMKA (UK) Ltd and EMKA Profiles Ltd, both based in the Coventry-Birmingham area, are looking forward to demonstrating their UK manufactured products at the PPMA Exhibition on 1st – 3rd October at the NEC on stand number G96.

EMKA Profiles Ltd specialise in the manufacture of spring steel inserted profiles which are a combination of edge protector with bonded sponge. These rubber profiles are a co-extrusion of solid and sponge rubber,…

Virtual Reality at the PPMA Show 2018

Cambridge, UK and Pittsford, NY – 24 August 2018: Also this year CAD Schroer’s customer Mariani will attend the PPMA show in Birmingham. The PPMA show is the UK's largest processing and packaging machinery exhibition, and is completely free for visitors to attend. CAD Schroer will be supporting Mariani at the show with the latest virtual and augmented reality technologies.

Mariani Presents in Virtual Reality at the show

Mariani is one…

Elesa at PPMA Exhibition, Birmingham, NEC, 25th – 27th September, Stand No. E0 …

The extensive Elesa range of standard machine elements is designed around the needs of the process and packaging industries. Much of this range will be on display at the 2018 PPMA Exhibition, taking place on 25th – 27th September at NEC Birmingham.

Featured on the Elesa stand - E02 - will be their IP65-7 direct drive digital position indicators with electronic mechanism for easy set up and readout on all forms…

Cutting factory project costs & timescales – PPMA Show 2012

When factory layouts need to change, flexible design software and competent project management significantly reduce costs and downtimes. CAD Schroer and WSP CEL team up to show how.

Cambridge, UK and Pittsford, NY – September 2012: At the UK’s premier processing and packaging industry event, CAD Schroer and WSP CEL once again team up to provide the complete factory layout and modelling solution - from providing large-scale design…

Astech Projects will Exhibit at PPMA 2011

See the dual-arm robot in action and receive a free Astech-branded golf ball

Leading systems integrator and bespoke machine builder, Astech Projects will be displaying its latest innovative technology and presenting its custom services on stand E85 at the PPMA Show, Birmingham NEC, UK from 27 – 29 September. Integrating equipment from major suppliers of commercial processing and packaging automation, Astech will display the Motoman SDA20D twin arm robot, in combination…

PPMA 2011 (27-29 Sept – NEC)

Cambridge, UK and Pittsford, NY – 24 August 2011:

PPMA 2011, the UK’s premier event for the processing and packaging industry, promises to deliver more than the latest machinery. The experts at stand C15 (NEC Hall 5) will be helping manufacturers tackle diverse project challenges.

Engineering managers tackling factory projects in changing markets must deliver new production lines quickly and cost-effectively. From 27-29 September, engineering software provider CAD Schroer…