Press release

Bizerba SliceCheck for Visual Inspections of Sliced Products

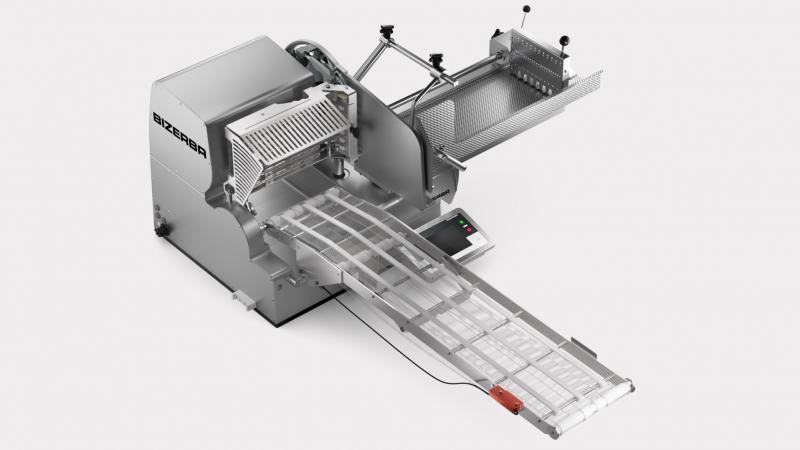

Bizerba‘s visual inspection system SliceCheck enables visual 100-percent inspections of sliced products before packaging. The real-time check detects mechanical damages and visual flaws including torn edges, holes or false orientation and rejects faulty products in time, thus saving material and cost.SliceCheck enables visual 100-percent inspections of sliced products before packaging.

Following the slicing process, SliceCheck’s visual inspection technology checks the top slice of each product stack for criteria like shape, size, position and composition. Faults including folds, cracks and imperfections result in the product’s ejection from the process before entering the packaging stage. Depending on the product, the inspection system checks and measures the product’s appearance with respect to fat content, bloodstains and marbling. For instance, the system checks cooked ham for the position and thickness of the crust. Raw ham, in turn, is checked for slices penetrated by fat or parts of the knuckle. In addition, SliceCheck detects spots that are penetrated by dark veins and do not meet the quality requirements. Thus, product quality can be ensured before the packaging process.

Continuous monitoring and adjusting of parameters while slicing and shaping ham helps to improve equipment productivity. By providing detailed information including the appearance, fat content and completeness of each product stack, the system creates a database that can be used to analyze and optimize the upstream slicing process. End-to-end traceability is also enabled by archiving images and production data.

SliceCheck also detects the height and orientation of the entire product stack, thus enabling precise placement in the package. This avoids flaws like inclusions of material in the sealed seam or leaky spots. Contactless quality checks also improve the hygiene conditions of the entire operation by reducing the risk of contamination due to human intervention.

Checking up to 100 stacks per minute per lane, the system can be straightforwardly connected to existing monitoring software or the company’s internal ERP system. Synchronous checking on two parallel lanes or asynchronous checking on multiple lanes is equally possible.

Apart from sliced products, SliceCheck can also be used for pastry including cookies or donuts.

About Bizerba

Bizerba offers its customers in industry, trade, and logistics a globally unique solutions portfolio of hardware and software around the central value "weight". This portfolio includes products and solutions related to slicing, processing, weighing, cashing, checking, commissioning and labeling. A wide range of services from consulting and service, labels and consumables to leasing complete the portfolio.

Since 1866 Bizerba has made a significant contribution to the developments in the area of weighing technology and today is represented in 120 countries. The customer base includes globally operating companies in trade and industry as well as retailers, bakeries and butcheries. With around 3.900 employees worldwide and with its headquarters in Balingen, Baden Wuerttemberg, Bizerba has been in the same family for five generations. Additional production facilities are located in Germany, Austria, Switzerland, Italy, France, Spain, China and USA. Bizerba also has a global network of sales and service locations.

Bizerba (UK) Ltd

2-4 Erica Road

Stacey Bushes

Milton Keynes

MK12 6HS

https://www.bizerba.com/en_gb/home/

Phone +44 1908 682-740

Fax +44 1908 682-777

E-mail info@bizerba.co.uk

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bizerba SliceCheck for Visual Inspections of Sliced Products here

News-ID: 540634 • Views: …

More Releases from Bizerba (UK) Ltd

New Industrial Food Slicer

Newly released our much-anticipated Industrial Food Slicer. After many years of success with the predecessor to this new unit, the A400 has sadly come to the end of its life. We will of course continue to support the A400 Variants however we have created a new beast that is going to take the food production for the SME sector by storm.

The new VSI T Industrial food slicer is now available…

COMPANY GAINS GREEN GLORY

BIZERBA UK have won the BRONZE Environment Award in the national campaign to find the greenest individuals, companies, councils and communities.

They competed against more than 800 other nominations in the Green Apple Awards for Environmental Best Practice with their project, ENERGY EFFICIENT CUTTING.

They were presented with their trophy and certificate at a glittering presentation ceremony hosted by Liz Kendall MP at the Houses of Parliament on November 12th, 2018.

As…

Digitize Packaging: Bizerba at the PPMA Show 2017

Across a three-stand layout, Bizerba introduces solutions around the topics of digital transformation, food safety, batch size, logistics and labels at this year’s PPMA Show. Current trends including industry 4.0, Internet of Things, predictive maintenance, the interaction of multiple systems as well as availability and service are all part of Bizerba’s solution portfolio.

Stand G10 – Convenience

CWE Combination Unit – demonstrating our fully integrated metal detector this device is to…