Press release

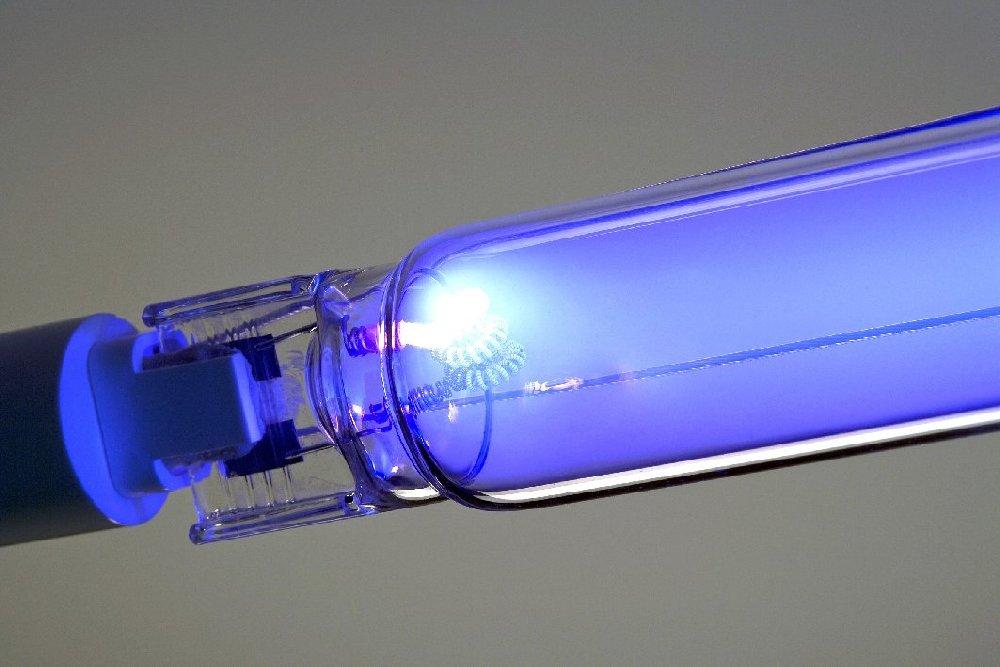

Powerful 800 Watt UV Amalgam Lamp for various applications in water treatment

UV Amalgam lamps with a unique coating save time and costs• Longlife technology doubles operating life

• Potential for savings in design of disinfection equipment

Heraeus is launching at AQUATECH a 800 Watt Amalgam lamp, the most powerful UV Amalgam lamp on the market. The new 800 Watt lamp features the unique Longlife coating from Heraeus Noblelight which considerably extends the operating life of UV lamps.

At the AQUATECH exhibition, which takes place from September 30 to October 3, 2008 in Amsterdam, the manufacturer of special light sources is showing UV lamps which are used for drinking water disinfection in waterworks, for wastewater treatment in sewage treatment plants and for the treatment of industrial process water. These include low pressure UVC lamps, compact, high power medium pressure UV lamps and GoldSpot Amalgam lamps.

With 800 Watts of electrical output and a length of 150 cm, this new development provides more than 30 percent more UV radiation than earlier 600 Watt lamps. Heraeus Noblelight has been successful in optimising the temperature management of the new 800 Watt lamp. The lamp works with active cooling. For the user, this means that the Amalgam lamp is easier to dim and, specifically, can be dimmed from 100 to 40 percent output, while maintaining a roughly constant efficiency of 35 to 40 percent.

The UV lamp also comes with a matched electronic power supply. The digital power supply is computer controlled and can be connected to a PC via an interface.

The 800 Watt lamp can be used in water treatment applications, generally wherever there is a need for high powers. It combines the benefits of medium pressure lamp technology in terms of high power, with the high efficiency of low pressure lamps.

In comparison to the other lamp technologies, UV Amalgam lamps deliver the best combination of efficiency and operating hours. Thanks to their higher power and excellent operating life, system builders require fewer lamps when designing a disinfection system. Consequently, there is great potential for savings, in terms of number of lamps, system components, energy consumption and maintenance costs.

Heraeus Noblelight has succeeded in doing this with the GoldSpot Amalgam lamps by eliminating the transmission loss of the quartz glass associated with conventional UV lamps to achieve a almost constant disinfection effect over the total operating life. With conventional UV lamps, mercury diffuses into the quartz, so that these lamps usually deliver only 50% of the initial UV output after 8000 operating hours. The Heraeus technology allows up to 16,000 operating hours with virtually constant UV output power, which is significantly more power than conventional lamps.

The new 880 Watt Amalgam lamp also benefits from Heraeus Longlife technology.

Ultraviolet light has an intensive effect. UVC radiation kills viruses and micro-organisms such as bacteria, without the addition of chemicals. There are no residual chemicals and the germ count in water and sources of infection are reliably reduced. The physical method of disinfection using UVC light is both dependable and cost-efficient.

Since its development of UV medium pressure technology in 1904, Heraeus Noblelight can look back to 100 years of experience in the development, production and application of UV lamps. Through innovations such as Longlife technology, Heraeus continues to set milestones in the field of UV lamps. Heraeus Noblelight is an original equipment supplier and the partner of choice for many systems builders involved in the disinfection of water, air and surfaces, as well as for manufacturers of systems for photo-chemistry and photo-oxidisation.

Heraeus Noblelight GmbH with its headquarters in Hanau and with subsidiaries in the USA, Great Britain, France, China, Australia and Puerto Rico, is one of the technology- and market-leaders in the production of specialist light sources. In 2007, Heraeus Noblelight had an annual turnover of 90 Million € and employed 666 people worldwide. The organisation develops, manufactures and markets infrared and ultraviolet emitters for applications in industrial manufacture, environmental protection, medicine and cosmetics, research, development and analytical laboratories.

Heraeus, the precious metals and technology group headquartered in Hanau, Germany, is a global, private company with over 155 years of tradition. Our businesses include precious metals, sensors, dental and medical products, quartz glass, and specialty lighting sources. With product revenues of € 3 billion and precious metal trading revenues of € 9 billion, as well as over 11,000 employees in more than 100 companies worldwide, Heraeus holds a leading position in its global markets.

Further information:

Manufacturer: Heraeus Noblelight GmbH

Heraeusstraße 12-14

D-63450 Hanau

Contact: Volker Adam

Phone +49 6181/35-9925, Fax +49 6181/35-9926

E-Mail hng-disinfection@heraeus.com

Press contact: Daniela Hornung

Heraeus Noblelight GmbH,

Marketing

Phone +49 6181/35-8539, Fax +49 6181/35-16 8539

E-Mail daniela.hornung@heraeus.com

www.heraeus-noblelight.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Powerful 800 Watt UV Amalgam Lamp for various applications in water treatment here

News-ID: 55522 • Views: …

More Releases from Heraeus Noblelight

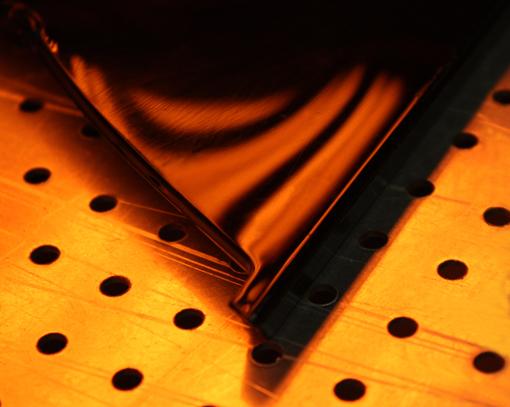

Infrared Heating helps to ensure quality in the manufacture of composite structu …

An infrared heating system from Heraeus Noblelight is helping to ensure the high quality of composite aerospace structures manufactured at the new GKN Aerospace facility at Western Approach, near Bristol. The system, which is used to provide interim processing of the laid-up composite rear spar assembly of the Airbus 350 XWB to prevent subsequent wrinkling, was custom-designed and developed in close co-operation with GKN Aerospace engineers following initial tests at…

Seven Good Reasons for the D2plus Light module

Heraeus Noblelight, one of the technology and market leaders in the field of specialty light sources will again exhibit at ANALYTICA, to be held in Munich, Germany in April 2012. Heraeus will introduce its “Seven Good Reasons for D2plus Light modules” at the show, making the life of instrument developers easier.

Developing new analytical instruments places ever-increasing demands on engineers, to design-in the best available light-source and avoid future operational problems.…

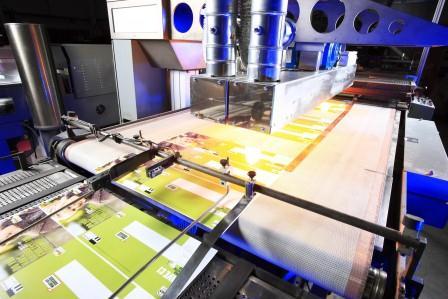

Specialty Light Sources for the Printing Industry

Hanau, February 2012

The Competence in Specialty Light Sources for printing systems

Special and personalized printing processes need special treatment. The ink of ink jet or laser printers need to be completely dried or cured before the printed sheets are passed on for subsequent operations such as stacking, cutting, folding or gluing. Infrared or UV technology is used for drying and curing, depending on the type of ink. Heraeus Noblelight presents its…

Infrared Emitters Improve Lacquered Surfaces

Many screens, internal claddings in cars and high value cosmetic packages are manufactured from plastics and contain a protective lacquer or finishing. The drying of the coating on the plastic components is not a trivial matter, for the surfaces need to be perfectly cured without applying to much heat to the plastic. Infrared heaters transfer energy in a contact-free manner and are easy to control. Consequently, the heat is precisely…

More Releases for Amalgam

Dental Amalgam Separators Market Key Players, Share and Forecast Outlook

"The global dental amalgam separators market is valued at approximately $150 million in 2024, with expectations to reach $250 million by 2034. This projection reflects a robust growth trajectory driven by increasing awareness of environmentally-safe dental practices and stringent regulations regarding amalgam waste management. The market is anticipated to grow at a Compound Annual Growth Rate (CAGR) of around 5.5% from 2025 to 2034."

Exactitude Consultancy., Ltd. released a research report…

Amalgam-Free Is the Way to Be: London's Bespoke Dentist Introduces Innovative Pr …

Image: https://www.getnews.info/wp-content/uploads/2024/08/1723468902.jpeg

In a groundbreaking move for dental health, London's pioneering dental clinic, The Bespoke Dentist, is revolutionising amalgam removal with innovative practices that prioritise patient safety and address global concerns.

In a groundbreaking move for dental health, London's pioneering dental clinic, The Bespoke Dentist, is revolutionising amalgam removal with innovative practices that prioritise patient safety and address global concerns. This pioneering approach is designed to reduce mercury exposure, protect patients, and…

Analysis of the Global Amalgam Filling in Dental Restoration Market 2023

Global Industrial aspects of Amalgam Filling in Dental Restoration Sales Market 2023-2029: The global Amalgam Filling in Dental Restoration Market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Netherlands-Ukraine War were considered while estimating market sizes.

North American market for Amalgam Filling in Dental Restoration is estimated…

The Future of Dental Amalgam Filling | 2022-2029 Market Analysis

Global Industrial aspects of Dental Amalgam Filling Sales Market 2023-2029: The global Dental Amalgam Filling Market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Netherlands-Ukraine War were considered while estimating market sizes.

North American market for Dental Amalgam Filling is estimated to increase from $ million in…

Amalgam Dental Material Market: Competitive Dynamics & Global Outlook 2025

LP INFORMATION recently released a research report on the Amalgam Dental Material market analysis, which studies the Amalgam Dental Material's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "Amalgam Dental Material Market 2020-2025" Research Report categorizes the global Amalgam Dental Material market by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players…

Global Amalgam Separator Industry Market Analysis & Forecast 2018-2023

Global Amalgam Separator Industry Market fuses the whole parts of the Amalgam Separator advertise. This incorporates broad investigation, late industry measurements and a forthcoming stream of the Amalgam Separator showcase. The report additionally portrays the measure of the Amalgam Separator advertise, factors controlling Amalgam Separator showcase development, different difficulties which influence showcase extension and financial unmistakable quality of the Amalgam Separator advertise the world over.

Get sample copy of report:

https://www.marketdensity.com/contact?ref=Sample&reportid=4495

Table…