Press release

Vegetable Oil Processing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, ROI, Raw Materials

Setting up a vegetable oil processing plant positions investors in one of the most stable and essential segments of the food and agro-processing value chain, backed by sustained global growth driven by rising population, increasing consumption of edible oils, growth in packaged food demand, and expanding applications across food, personal care, and industrial sectors. As urbanization accelerates, consumer lifestyles shift toward convenience and packaged foods, and regulatory frameworks increasingly support healthy and fortified oil products, the global vegetable oil processing industry continues to present compelling opportunities for manufacturers and entrepreneurs seeking long-term profitability in a high-demand sector.Market Overview and Growth Potential:

The global vegetable oil market demonstrates a strong growth trajectory, valued at USD 293.99 Billion in 2025. According to IMARC Group's comprehensive market analysis, the market is expected to reach USD 448.70 Billion by 2034, exhibiting a CAGR of 4.8% from 2026 to 2034. This sustained expansion is driven by rising population, increasing consumption of edible oils, growth in packaged food demand, and expanding applications across food, personal care, and industrial sectors.

Vegetable oil refers to oils extracted from plant sources, which include soybean, palm, sunflower, rapeseed, mustard, cottonseed, and groundnut. The oils serve multiple culinary functions because they contain high energy content and various cooking properties, which make them suitable for use in cooking, frying, baking, and food preparation. Processed foods, margarine, salad dressings and sauces, and snacks depend on vegetable oils, which function as fundamental components. The products find application in food production, and they serve as common ingredients for cosmetics and soaps, lubricants and pharmaceuticals, and biodiesel production.

The global vegetable oil industry has experienced continuous growth since the population increase, as more people move to cities and buy more packaged and processed food products. For instance, the OECD FAO Agricultural Outlook 2025 to 2034 projected rising per capita vegetable oil consumption in emerging economies at about 0.5% annually as incomes and urbanization increased. Food applications still dominate demand, while biofuel feedstock near 18% adds momentum, collectively accelerating overall vegetable oil market growth. The growth of quick-service restaurants and food delivery services has led to an increase in people using frying and cooking oils. In April 2025, Repsol and Bunge announced progress in developing renewable fuels in Europe using novel crops such as camelina and safflower as low-carbon feedstocks, with potential lifecycle greenhouse gas emission reductions of up to 90% compared to conventional diesel - underscoring the growing market demand for sustainable vegetable oil feedstocks across global energy and food supply chains.

Plant Capacity and Production Scale:

The proposed vegetable oil processing facility is designed with an annual production capacity ranging between 100,000-300,000 MT of oilseeds, enabling economies of scale while maintaining operational flexibility. This capacity range allows processors to cater to diverse market segments - from food and beverage manufacturers and retail edible oil brands to foodservice and HoReCa establishments, cosmetics producers, and biofuel producers - ensuring steady demand and consistent revenue streams across multiple industry verticals. The facility is designed to serve both domestic supply chains and export requirements, positioning the plant at the intersection of agricultural processing efficiency and trade facilitation.

Request for a Sample Report: https://www.imarcgroup.com/vegetable-oil-processing-plant-project-report/requestsample

Financial Viability and Profitability Analysis:

The vegetable oil processing business demonstrates healthy profitability potential under normal operating conditions. The financial projections reveal:

Gross Profit Margins: 10-15%

Net Profit Margins: 3-6%

These margins are supported by stable demand across food and beverage, foodservice, cosmetics, and biofuel sectors, value-added specialty oil positioning including cold-pressed and fortified oils, and the critical role of vegetable oils as a daily consumption staple ensuring consistent non-cyclical demand worldwide. The project demonstrates strong return on investment (ROI) potential, making it an attractive proposition for both new entrants and established agro-processing or food manufacturers looking to diversify their portfolio.

Cost of Setting Up a Vegetable Oil Processing Plant:

Understanding the operating expenditure (OpEx) is crucial for effective financial planning and cost management. The cost structure for a vegetable oil processing plant is primarily driven by:

Raw Materials: 85-90% of total OpEx

Utilities: 5-8% of OpEx

Other Expenses: Including labor, packaging, transportation, maintenance, depreciation, and taxes

Raw materials constitute the largest portion of operating costs, with oilseeds (soybean, sunflower, etc.) being the primary input material. Hexane, chemicals, and packaging form the secondary raw material requirements. Establishing long-term contracts with reliable oilseed suppliers helps mitigate price volatility and ensures consistent raw material supply, which is critical given that oilseed price fluctuations represent the most significant cost factor in vegetable oil processing.

Capital Investment Requirements:

Setting up a vegetable oil processing plant requires substantial capital investment across several critical categories:

Land and Site Development:

Selection of an optimal location with strategic proximity to oilseeds (soybean, sunflower, etc.), hexane, chemicals, and packaging suppliers. Proximity to target food processing, retail, and foodservice markets will help minimize distribution costs. The site must have robust infrastructure, including reliable transportation, utilities, and waste management systems. Compliance with local zoning laws, food safety regulations, and environmental requirements must also be ensured.

Machinery and Equipment:

The largest portion of capital expenditure (CapEx) covers specialized processing equipment essential for production. Key machinery includes:

• Seed cleaners: for removal of foreign matter, dust, and impurities from raw oilseeds prior to processing to ensure product quality

• Expellers or solvent extractors: for mechanical pressing or solvent-based extraction of crude oil from cleaned and conditioned oilseeds

• Oil filters: for removal of meal fines and solid impurities from crude extracted vegetable oil to achieve initial clarification

• Refining units: for degumming, neutralization, and washing of crude oil to remove phosphatides, free fatty acids, and other impurities

• Bleaching systems: for removal of color pigments, trace metals, and oxidation products through activated bleaching earth treatment

• Deodorization systems: for removal of volatile flavor and odor compounds through steam stripping under high temperature and vacuum conditions

• Storage tanks: for safe storage of crude oil, intermediate products, refined oil, and by-products including oil cakes and fatty acid distillates

• Packaging lines: for filling, sealing, and labeling of finished vegetable oil into consumer packs, bulk containers, and industrial drums

Civil Works:

Building construction, factory layout optimization, and infrastructure development designed to enhance workflow efficiency, ensure workplace safety, and minimize material handling complexities throughout the processing operation. The layout should be optimized with separate areas for raw material storage, seed preparation zone, extraction section, refining and bleaching area, deodorization unit, quality control station, finished goods warehouse, utility block, and administrative block.

Other Capital Costs:

Pre-operative expenses, machinery installation costs, regulatory compliance and food safety certification costs, initial working capital requirements, and contingency provisions for unforeseen circumstances during plant establishment.

Speak to Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8860&flag=C

Major Applications and Market Segments:

Vegetable oil products find extensive applications across diverse market segments, demonstrating their versatility and critical importance across the global food and industrial supply chain:

Food and Beverage Industry:

The food manufacturing process requires vegetable oils as vital cooking and processing components, which deliver uniform flavor and quality together with thermal stability for food production. Processed foods, margarine, salad dressings and sauces, and snacks depend on vegetable oils as fundamental ingredients. Vegetable oils also serve as emulsifiers and stabilizers in processed foods, aiding in the blending of ingredients and preventing separation in products like mayonnaise, dressings, and spreads.

Foodservice and HoReCa Sector:

Refined vegetable oils, with their ability to withstand high temperatures, make them an economical choice for hotels, restaurants, and institutional kitchens, which require oils for continuous frying operations. The growth of quick-service restaurants and food delivery services has led to an increase in demand for high-stability frying and cooking oils with extended shelf life and consistent performance.

Cosmetics and Personal Care Industry:

Refined and specialty vegetable oils function as base ingredients in skincare, haircare, and cosmetic formulations due to their emollient properties. Vegetable oils serve as common ingredients for cosmetics, soaps, and pharmaceuticals, providing moisturizing, nourishing, and conditioning properties essential for personal care product formulations.

Biofuel and Oleochemical Industry:

Vegetable oils support biodiesel production and oleochemical manufacturing, which creates renewable energy sources and environmentally friendly chemical products. Biofuel feedstock demand for vegetable oils represents approximately 18% of total demand, adding significant momentum to overall market growth and creating additional revenue opportunities for integrated vegetable oil processors.

Why Invest in Vegetable Oil Processing?

Several compelling factors make vegetable oil processing an attractive investment opportunity:

Essential Dietary Commodity:

Vegetable oils remain a daily consumption staple, ensuring stable and long-term demand across global markets. This structural indispensability ensures consistent, non-cyclical demand that spans across all food manufacturing, retail, and foodservice sectors.

Diverse End-use Applications:

The processing unit can cater to food, cosmetic, pharmaceutical, and energy sectors, improving revenue diversification. Diverse industrial applications ensure that demand is sustained across the business cycle and across different economic conditions.

Scalable Production Model:

Enable companies to expand their production capacity through incremental steps, which add new downstream operations for refining and value-added products. The vegetable oil processing model allows manufacturers to start with basic extraction and progressively add refining, bleaching, deodorization, and specialty oil capabilities.

Import Substitution and Export Potential:

Domestic processing creates direct economic benefits since it decreases import needs while allowing exports of processed oils and their by-products. The alignment with global trade growth and rising demand in emerging economies creates significant export opportunities for high-quality refined vegetable oil products.

By-product Utilization:

The company generates extra income through the usage of oil cakes and fatty acid distillates, which serve as animal feed and industrial products. By-product revenue streams enhance overall plant profitability and support the circular economy model in agro-processing operations.

Opportunities for Recycling and Circular Economy:

The market demand for renewable biofuels and sustainable oleochemicals creates persistent business prospects which support environmentally friendly production facilities within local communities, aligning with global sustainability mandates and circular economy principles.

Manufacturing Process Excellence:

The vegetable oil processing operation involves several precision-controlled stages to deliver standardized, high-purity, and market-ready products:

• Seed Cleaning and Preparation: Oilseeds are cleaned using seed cleaners to remove foreign matter, dust, and impurities, then conditioned with heat and moisture for optimal oil extraction

• Oil Extraction: Cleaned seeds undergo mechanical pressing through expellers or solvent extraction using hexane to extract crude oil from the oilseed material

• Crude Oil Filtration: Extracted crude oil is filtered to remove meal fines and solid impurities to achieve initial clarification before downstream refining

• Degumming: Crude oil is treated with water or acid to remove phosphatides and gums that would otherwise cause instability and reduce shelf life

• Neutralization: Free fatty acids are removed through alkali treatment to produce neutralized oil with improved stability and flavor characteristics

• Bleaching: Neutralized oil is treated with activated bleaching earth under vacuum to remove color pigments, trace metals, and oxidation products

• Deodorization: Bleached oil undergoes steam stripping under high temperature and vacuum to remove volatile flavor and odor compounds producing neutral-tasting refined oil

• Quality Inspection: Finished refined vegetable oil is tested for free fatty acid content, peroxide value, color, clarity, and compliance with food safety and international standards

• Packaging: Approved oil is filled into consumer packs, bulk containers, or industrial drums on automated packaging lines for distribution to food, retail, and industrial customers

Buy Now: https://www.imarcgroup.com/checkout?id=8860&method=2175

Industry Leadership:

The global vegetable oil processing industry is led by established multinational processors with extensive production capacities and diverse application portfolios. Key industry players include:

• Archer Daniels Midland Company

• Sime Darby Plantation Berhad

• Bunge Limited

• Olam International Limited

• Cargill Incorporated

These companies serve diverse end-use sectors including food processing, retail edible oil, foodservice, personal care, and biofuel sectors, demonstrating the broad market applicability of refined vegetable oil products across global food and industrial supply chain verticals.

Recent Industry Developments:

December 2025: The Government of India emphasized progress on the National Mission on Edible Oils to strengthen the oilseed ecosystem and boost domestic edible oil output, targeting 6.5 lakh hectares under oil palm by 2025-26 and 28 lakh tons of crude palm oil by 2029-30. As of November 2025, 2.50 lakh hectares were under the mission's oil palm program, bringing total coverage to 6.20 lakh hectares, and the oilseed program aims to raise production from 39 million to 69.7 million tons by 2030-31.

April 2025: Repsol and Bunge announced progress in developing renewable fuels in Europe by using novel crops such as camelina and safflower as low-carbon feedstocks. The initiative targets production of renewable diesel and sustainable aviation fuel, with potential lifecycle greenhouse gas emission reductions of up to 90% compared to conventional diesel, using Repsol's industrial facilities in Spain.

Conclusion:

The vegetable oil processing sector presents a strategically positioned investment opportunity at the intersection of global food security growth, agro-processing industrialization, and sustainable energy transition. With favorable profit margins ranging from 10-15% gross profit and 3-6% net profit, strong market drivers including rising population and urbanization driving edible oil consumption, growth in packaged food and foodservice sectors, expanding biofuel and oleochemical applications, and the fundamental role of vegetable oil as an essential dietary commodity, establishing a vegetable oil processing plant with an annual production capacity of 100,000-300,000 MT of oilseeds offers significant potential for long-term business success and sustainable returns. The combination of scalable and cost-efficient processing operations, alignment with global food trade growth, diverse application portfolio spanning food to energy, and growing by-product utilization and circular economy business models creates an attractive value proposition for agro-processing and food industry investors committed to quality manufacturing and operational excellence.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers create a lasting impact. The company excels in understanding its clients' business priorities and delivering tailored solutions that drive meaningful outcomes. IMARC Group provides a comprehensive suite of market entry and expansion services, including market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No: (D) +91 120 433 0800

United States: (+1-201-971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vegetable Oil Processing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, ROI, Raw Materials here

News-ID: 4399076 • Views: …

More Releases from IMARC Group

Trinitrotoluene Production Plant DPR & Unit Setup 2026: Demand Analysis and Proj …

Setting up a trinitrotoluene production plant involves strategic planning, substantial capital investment, and a comprehensive understanding of production technologies. This critical explosive compound serves military and defense, mining and quarrying, construction and demolition, and industrial explosives manufacturing applications. Success requires careful site selection, efficient nitration processes, stringent safety protocols for handling hazardous materials, reliable raw material sourcing, and compliance with industrial safety regulations to ensure profitable and sustainable operations.

Market Overview…

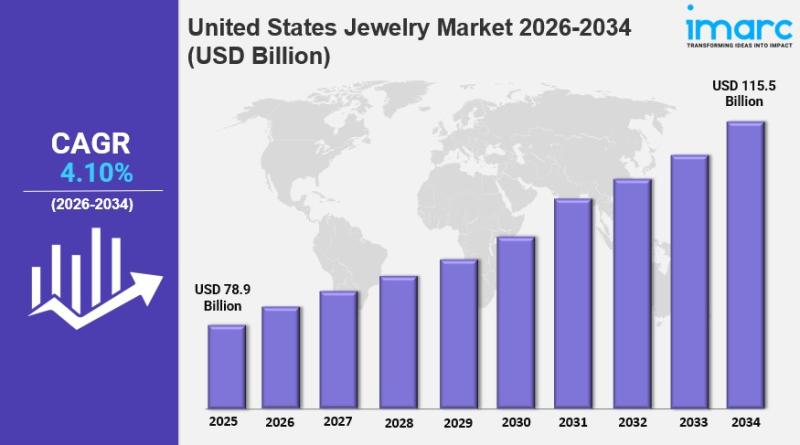

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

More Releases for Vegetable

Vegetable Juices Market Size Analysis by Application, Type, and Region: Forecast …

USA, New Jersey- According to Market Research Intellect, the global Vegetable Juices market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Vegetable Juices Market is experiencing significant growth, driven by increasing consumer awareness about health, nutrition, and natural food products. As more individuals shift toward…

Canned Vegetable Market Report 2024 - Canned Vegetable Market Growth And Share

"The Business Research Company recently released a comprehensive report on the Global Canned Vegetable Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

According to The Business Research Company's, The canned vegetable market size…

Fruit - Vegetable Processing Market

Fruit - Vegetable Processing Market report gives detailed explanation of the estimations about the existing state of the market, market size and market share, revenue generated from the product sale, and necessary changes required in the future products are given in an appropriate way. A swiftly transforming market place increases the value of market research report and hence Fruit - Vegetable Processing Market report has been created in a way…

Processed Vegetable Market Size, Share | Processed Vegetable Industry Future Gro …

Global Processed Vegetable Market Report provides a detailed industry overview along with the analysis of Cost Structure, Supply Chain, Development Techniques, Retailers Analysis, Financial Support, business Strategies, Marketing Channels. Global Processed Vegetable Market research report provides a point-by-pointIn-Depth analysis of global market size, regional and country-level market size, segmentation market growth, market share, competitive Landscape, sales analysis, the impact of domestic and global market players, value chain optimization, trade regulations,…

Global Textured Vegetable Protein Market

According to a new market research report published by Global Market Estimates, the Global Textured Vegetable Protein Market is expected to grow at a CAGR of 6.40% during the forecast period. The increasing adoption of meat alternatives among consumers, along with the growing demand for protein-rich food is some of the major factors influencing the growth of the textured vegetable protein market.

Browse 148 Market Data Tables and 90 Figures spread…

Frozen Fruits & Vegetable Processing Unit

Fruits and Vegetables Processing sector is one of the largest and most dynamic sectors of the food industry. Processed Fruits & Vegetables covers various categories, like sun-dried, Machine dried, frozen, dehydrated and frozen, pickled with natural substances, pickled with chemicals, etc. Amongst which the popularity of frozen fruits and vegetables in daily diets is steadily increasing, driven by shifting food preferences throughout the world.

The global frozen fruits and vegetable market…