Press release

Laser Cutting Machine for Stainless Steel: GWEIKE Publishes a Practical Guide to Cleaner Edges and More Stable Production

Laser Cutting Machine for Stainless Steel: GWEIKE Publishes a Practical Guide to Cleaner Edges and More Stable Production

Stainless steel is widely used across enclosures, kitchen equipment, HVAC parts, elevators, and general fabrication. However, compared with mild steel, stainless cutting can be more sensitive to assist gas selection, nozzle and optics condition, focus offset, and piercing strategy. In production environments, small parameter drift or consumable wear can quickly show up as visible defects-burn marks, heavy bottom dross, rough edges, inconsistent kerf, or unstable piercing-leading to additional grinding, rework, and lower throughput.

The new guide consolidates a practical workflow that operators and process engineers can use to stabilize cutting performance and reduce avoidable post-processing.

Guide link:

https://www.gwklaser.com/about/technical/Laser-Cutting-Stainless-Steel.html

What the guide helps manufacturers solve

GWEIKE's stainless guide is built around the most common "shop-floor complaints" and how teams typically fix them in a structured order:

· Bottom dross and heavy slag that increases finishing time

· Heat tint / edge discoloration that affects appearance-sensitive parts

· Rough edge texture and inconsistent cut quality across a batch

· Piercing instability (spatter, incomplete pierce, inconsistent lead-ins)

· Quality drift over time caused by consumable wear or optics contamination

Common Symptoms → Likely Causes → First Actions (shop-floor quick reference)

Below is a condensed "first-response" reference derived from the guide's troubleshooting workflow. It is designed to help teams isolate root causes with fewer trial-and-error iterations.

1) Heavy bottom dross / slag

· Likely causes: nozzle wear or contamination; unstable assist gas delivery; focus offset drift; insufficient ejection efficiency at the cut front.

· First actions: inspect/replace nozzle and protective window; verify gas pressure stability and line integrity; re-check focus and standoff consistency; run a short straight-line test cut to confirm stability before batch production.

2) Burn marks / edge discoloration (appearance issues)

· Likely causes: assist gas strategy not aligned with appearance goal; excessive heat input per unit length; pierce-to-cut transition instability; optics contamination increasing absorbed heat.

· First actions: confirm assist gas and quality; check optics cleanliness; validate piercing routine and lead-in; reduce "hidden" heat accumulation by stabilizing the process window before changing multiple parameters.

3) Rough edges / striations worsen mid-batch

· Likely causes: consumables degrading during runtime; lens/protective window contamination; gas pressure drift; inconsistent standoff from height control variation.

· First actions: stop and inspect nozzle/protective window; confirm height control behavior; check gas regulator stability; re-qualify on a first-article sample and document the stable setup.

4) Piercing unstable (spatter, incomplete pierce, blown holes)

· Likely causes: piercing routine not matched to thickness; nozzle condition poor; focus mismatch; gas pressure or timing instability.

· First actions: verify nozzle condition first; confirm focus position; validate gas timing and pressure consistency; re-run pierce test pattern before starting nested parts.

5) Inconsistent kerf / dimensional drift

· Likely causes: focus/standoff inconsistency; thermal accumulation on dense nests; mechanical or gas stability issues; optics contamination.

· First actions: confirm standoff repeatability; reduce risk by validating on representative geometry; check optics and consumables; stabilize gas delivery before changing many cutting parameters.

Equipment context and selection references

To help readers connect stainless process requirements with machine evaluation, GWEIKE points to its overview of system types and configurations:

https://www.gwklaser.com/laser-cutting-machine.html

The company also references a comparison guide explaining when manufacturers typically choose fiber or CO2 systems based on application fit and material mix:

https://www.gwklaser.com/about/technical/fiber-vs-co2-laser-cutting.html

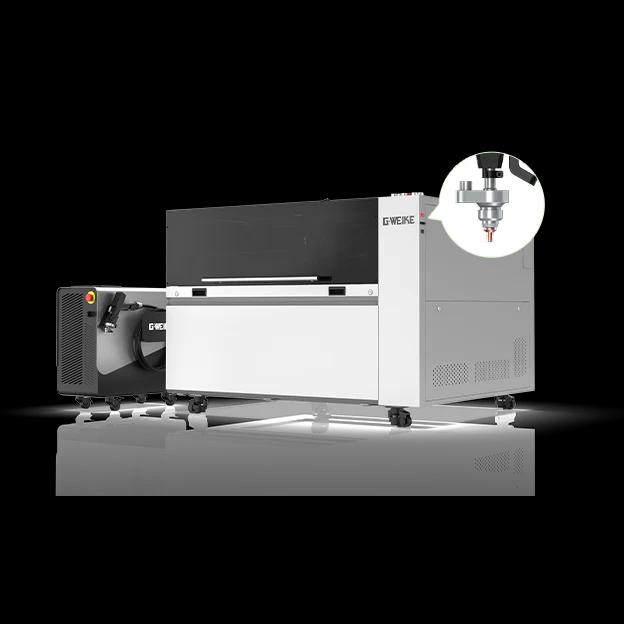

For manufacturers evaluating enclosed platforms often considered for stainless applications, GWEIKE highlights a representative configuration path with LF3015LN:

https://www.gwklaser.com/fiberlaser/LF3015LN.html

For factories prioritizing productivity-oriented integration and production workflow design, the guide also references GA3 as another example of an industrial configuration approach:

https://www.gwklaser.com/fiberlaser/GA3.html

"Stainless cutting is where process control becomes visible," said a GWEIKE applications specialist. "If teams standardize the basics-gas delivery, nozzle condition, focus discipline, and piercing checks-they can stabilize quality faster and reduce the hidden cost of rework."

Availability

The stainless steel cutting guide is available now for production teams, process engineers, and procurement groups evaluating or operating a laser cutting machine for stainless applications.

- GWEIKE Laser Technology Co., Ltd.

- Hotline:+86-13290249306

- 13A, Building D, Big Data Industrial Base, Xin Lou Street, High-tech Zone, Jinan, Shandong, China

- E-mail:gwk@wklaser.com

- Fax:0531-88912386

- WhatsAPP/Wechat/ :+86-13290249306

GWEIKE provides industrial laser equipment solutions for global manufacturers, supporting metal fabrication with application-oriented system configurations and process guidance.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Laser Cutting Machine for Stainless Steel: GWEIKE Publishes a Practical Guide to Cleaner Edges and More Stable Production here

News-ID: 4325617 • Views: …

More Releases from GWEIKE Laser Technology Co., Ltd.

GWEIKE Launches G3 Basic Dual-Laser Desktop Engraver for Metal and Non-Metal App …

GWEIKE(https://www.gweikecloud.com/), a global manufacturer of laser processing equipment, has officially introduced the G3 Basic Dual-Laser Desktop Engraving Machine, a compact system designed to support both metal and non-metal laser processing within a single platform.

Unlike conventional desktop engravers that rely on a single laser source, the G3 Basic integrates a 20W fiber laser and a 20W diode laser, allowing users to engrave and mark stainless steel, aluminum, and coated metals while…

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine(https://www.gwklaser.com/co2/LC1325M.html) for Large Format Multi Material Production

1250 x 2500 mm working area, auto focus height control, and adjustable power range support workshops and factories processing acrylic, wood, leather, fabrics, and paper.

GWEIKE(https://www.gwklaser.com/) announced the LC1325M, a hybrid CO2 laser cutting machine(https://www.gwklaser.com/co2/) built for large format, multi material production environments where daily orders change frequently. The LC1325M is designed to help manufacturers standardize cutting and…

Laser Cutting Machine Basics: New Desktop Guide Explains Types, Key Specs, and B …

As desktop laser cutters become more accessible, more first-time users are searching "laser cutting machine" with a practical intent: select a setup that matches real materials, produces clean edges, and stays repeatable day after day. Yet beginners often discover that comparing machines by wattage alone does not predict outcomes-especially when CO2 and fiber systems behave very differently on common materials such as wood, acrylic, stainless steel, and coated metals.

To reduce…

Multi-Process Metal Laser Workstations Explained: When a "6-in-1" Setup Makes Se …

Multi-process laser workstations are becoming popular because many small shops and makers do not want separate machines for every task. A single bench-type system can combine several metal processes-typically cutting (thin), welding, cleaning, engraving, and marking-so you can prototype, finish, and label parts in one workflow.

If you want deeper background while reading, here are three optional references :

· 6-in-1 metal laser workstation overview: https://www.gweikecloud.com/blogs/news/gweike-m-series-6-in-1-metal-laser-workstation

· Engraving vs cutting vs marking (why…

More Releases for Stainless

Stainless Steel Market 2020 Growth by key players Jindal Stainless, Aperam Stain …

Global Market Insights, Inc., announces an ongoing comprehensive report on the Stainless Steel Market.

This report provides an exhaustive account of the industry including:

o Stainless Steel Market size, annual forecast from 2020 to 2026

o Major stainless steel industry trends, technology evolution, economic indicators and business challenges

o Regulatory and geopolitical trends impacting the industry

o Business drivers and pitfalls impacting key regional markets

o Competitive landscape of the industry and detailed profiles on the…

What's driving the Stainless Steel Market Growth? Jindal Stainless, ArcelorMitta …

North America led by U.S. stainless steel market may witness significant growth by increasing application scope in medical, oil & gas and heavy industries. High-grade stainless steel plays vital role in construction of valves, pipes, and storage tanks to provide resistance to corrosion over a wider range of temperatures. Growing adoption of stainless steel in oil & gas industry for off-shore oil rigs is expected to boost the overall market…

What's driving the Stainless Steel Market Growth? Jindal Stainless, ArcelorMitta …

Europe driven by France, UK and Germany stainless steel market may witness high growth owing to positive application outlook in automotive industry owing to its high strength that allows for thinner containers, saving fuel costs, whereas its resistance to corrosion helps in minimizing the maintenance and cleaning costs.

Asia Pacific led by China, India and Japan stainless steel market should witness significant growth owing to rise in demand for renewable energy…

Stainless Steel Welded Pipes Market | key player - Pohang Iron & Steel (Posco), …

Looking at the current market trends as well as the promising demand status of the “Stainless Steel Welded Pipes Market” it can be projected that the future years will bring out positive outcomes. This research report added by MRRSE on its online portal delivers clear insight about the changing tendencies across the global market. Readers can gather prime facets connected to the target market which includes product, end-use and application;…

Stainless Steel Market Scenario Highlighting Major Drivers & Trends, 2018 – 20 …

Adroit Market Research offers 2018 report on “Stainless Steel Market 2025” that evaluates industry growth trends through historical data and estimates future prospects based on comprehensive research. The report extensively provides the market share, growth, trends and forecasts for the period 2018-2025.

About the Stainless Steel Market:

Global stainless steel market trends augmented as its commendable properties -low maintenance, aesthetic appeal and ease of fabrication helps it to rank higher over the…

Stainless Steel Tube Market Global Forecast 2018| Studied By Outokumpu, Acerinox …

UpMarketResearch published an exclusive report on “ Stainless Steel Tube market” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 128 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability. This report focuses on the Stainless Steel Tube market, especially in North America, Europe and Asia-Pacific, South America,…