Press release

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine

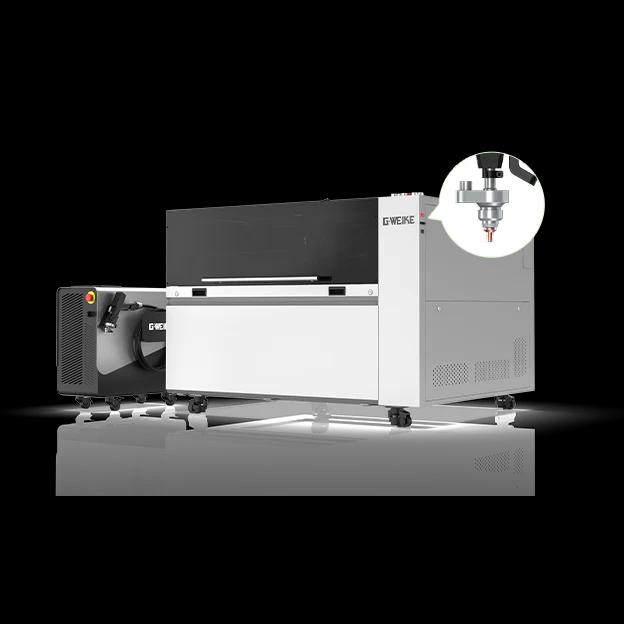

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine(https://www.gwklaser.com/co2/LC1325M.html) for Large Format Multi Material Production1250 x 2500 mm working area, auto focus height control, and adjustable power range support workshops and factories processing acrylic, wood, leather, fabrics, and paper.

GWEIKE(https://www.gwklaser.com/) announced the LC1325M, a hybrid CO2 laser cutting machine(https://www.gwklaser.com/co2/) built for large format, multi material production environments where daily orders change frequently. The LC1325M is designed to help manufacturers standardize cutting and engraving workflows across common non metal materials such as acrylic, wood products, leather, textiles, and paper, while keeping setup and changeovers efficient on a single platform.

In many small and mid size manufacturing operations, the real cost driver is not peak cutting speed. It is production friction: repeated focus checks, repeated parameter adjustments, inconsistent results across operators, and the time lost moving jobs between different machines. This is especially true for signage and display production, woodworking, packaging prototyping, and leather or textile cutting, where a shop may run multiple materials in the same shift. The LC1325M is positioned to reduce that friction by combining a large working area with motion and control features that aim to improve repeatability, simplify focusing, and keep output stable across mixed order types.

A large format platform for mixed workflows

The LC1325M uses a 1250 x 2500 mm working area that suits common sheet sizes and helps reduce the need to split parts across multiple runs. For many operators, the advantage of a larger bed is practical: fewer re loads, fewer alignment mistakes, cleaner batching, and easier nesting of mixed part sizes on one sheet. When production includes both cutting and engraving tasks, a stable large format platform can also help maintain more consistent geometry across the full working range.

Key engineering highlights focused on stability and setup efficiency

GWEIKE positions the LC1325M with a set of practical features aimed at improving motion stability and reducing operator dependent adjustments during everyday operation:

- High precision transmission for stable movement over the long axis

A Taiwan TBI ball screw supports motion consistency across the machine travel, which is especially relevant for large format layouts where small drift can accumulate over long vectors.

- Servo drive system for reliable production operation

Panasonic servo motor architecture supports smoother motion control and stable performance over extended use, which can help reduce the variability that often appears when shops run longer duty cycles and frequent job changes.

- Auto focus height control for faster material switching

An Au3tech capacitive height controller supports auto focus behavior, reducing the need for repeated manual focusing steps when operators move between different materials and thicknesses.

- Adjustable power range for mixed priorities

A Yongli 300W beam combination laser tube supports continuous 50 to 300W power adjustment, allowing operators to match output to material needs. In practical terms, some jobs require cleaner edges and lower heat impact, while others prioritize higher throughput when quality targets allow.

Materials and application scenarios

The LC1325M is positioned for cutting and engraving common non metal materials often found in mixed production workshops, including clothing fabrics, leather, wood products, acrylic, and paper. These materials appear frequently in industries where order mix changes daily and where a single reliable platform can improve scheduling and reduce work in process.

Typical use cases include:

- Signage and display production

Acrylic cutting and engraving, layered signage components, backlit letter parts, and display panels.

- Wood and craft manufacturing

MDF and plywood cutting, decorative patterns, jigs and fixtures, and custom product components.

- Leather and textile workflows

Cutting patterns for leather goods, apparel components, patches, and textile templates, with repeatable results that reduce manual trimming.

- Packaging and prototyping

Paper and board cutting for samples, mockups, inserts, and quick iteration cycles.

Hybrid positioning and sample based validation for specialized needs

The LC1325M is also described as a hybrid solution that may support selected thin metal use cases depending on material type, thickness, and configuration. Because performance in thin metal applications depends on the exact alloy, thickness range, and process setup, GWEIKE recommends validating any metal use case through sample testing using the actual material and design file before finalizing the configuration for production.

Technical snapshot for quick screening

Published specifications for LC1325M include:

- Working area: 1250 x 2500 mm

- Machine size: 3930 x 1869 x 1250 mm

- Positioning accuracy: +/- 0.05 mm per meter

- Positioning speed: 20 m per minute

- Power supply: 220V +/- 10 percent, 10A

Designed to reduce daily production friction

For many owners and production managers, the decision to adopt a large format CO2 system is driven by measurable operational outcomes:

- Less time spent on repeated manual focusing and setup checks

- More consistent output across different operators and shifts

- Faster turnaround when orders shift between acrylic, wood, textile, and leather jobs

- Less handling and fewer re loads due to a larger working bed

By focusing on a stable motion platform, auto focus height control, and adjustable power output, the LC1325M is intended to support workshops that want a predictable process for mixed materials without building separate specialized lines for each product category.

Pricing, specifications, and sample testing

Manufacturers can learn more about the LC1325M, request pricing, download specifications, or request a sample test through the product page:

https://www.gwklaser.com/co2/LC1325M.html

Press and business inquiries

For more information, product questions, or sample test requests, please use the contact form:

https://www.gwklaser.com/contact/

Company: GWEIKE TECH CO., LTD. (GWEIKE Cloud)

Address: 13A, Building D, Big Data Industrial Base, Xinluo Avenue, High-Tech Zone, Jinan, Shandong, China

Website: https://www.gweikecloud.com/

Email (Press): allison@wklaser.com

GWEIKE provides laser equipment for cutting, welding, and related manufacturing workflows, supporting workshops and factories with solutions designed to improve production efficiency and consistency across common industrial and light manufacturing applications.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine here

News-ID: 4358700 • Views: …

More Releases from GWEIKE Laser Technology Co., Ltd.

GWEIKE Launches G3 Basic Dual-Laser Desktop Engraver for Metal and Non-Metal App …

GWEIKE(https://www.gweikecloud.com/), a global manufacturer of laser processing equipment, has officially introduced the G3 Basic Dual-Laser Desktop Engraving Machine, a compact system designed to support both metal and non-metal laser processing within a single platform.

Unlike conventional desktop engravers that rely on a single laser source, the G3 Basic integrates a 20W fiber laser and a 20W diode laser, allowing users to engrave and mark stainless steel, aluminum, and coated metals while…

Laser Cutting Machine Basics: New Desktop Guide Explains Types, Key Specs, and B …

As desktop laser cutters become more accessible, more first-time users are searching "laser cutting machine" with a practical intent: select a setup that matches real materials, produces clean edges, and stays repeatable day after day. Yet beginners often discover that comparing machines by wattage alone does not predict outcomes-especially when CO2 and fiber systems behave very differently on common materials such as wood, acrylic, stainless steel, and coated metals.

To reduce…

Multi-Process Metal Laser Workstations Explained: When a "6-in-1" Setup Makes Se …

Multi-process laser workstations are becoming popular because many small shops and makers do not want separate machines for every task. A single bench-type system can combine several metal processes-typically cutting (thin), welding, cleaning, engraving, and marking-so you can prototype, finish, and label parts in one workflow.

If you want deeper background while reading, here are three optional references :

· 6-in-1 metal laser workstation overview: https://www.gweikecloud.com/blogs/news/gweike-m-series-6-in-1-metal-laser-workstation

· Engraving vs cutting vs marking (why…

Metal Laser Guides: Color Engraving, 3D Relief, Welding

GWEIKE Cloud today announced the release of an expanded set of practical workflow resources designed to help makers, small fabrication shops, and metal-marking businesses achieve consistent results across three high-demand applications: stainless steel color engraving, 3D relief/embossing engraving, and everyday laser welding.

As demand grows for premium-looking metal products and fast turnaround, many operators face the same operational challenge: output quality depends too heavily on individual experience, which increases rework and…