Press release

Laser Cutting Machine Basics: New Desktop Guide Explains Types, Key Specs, and Buying Checklist

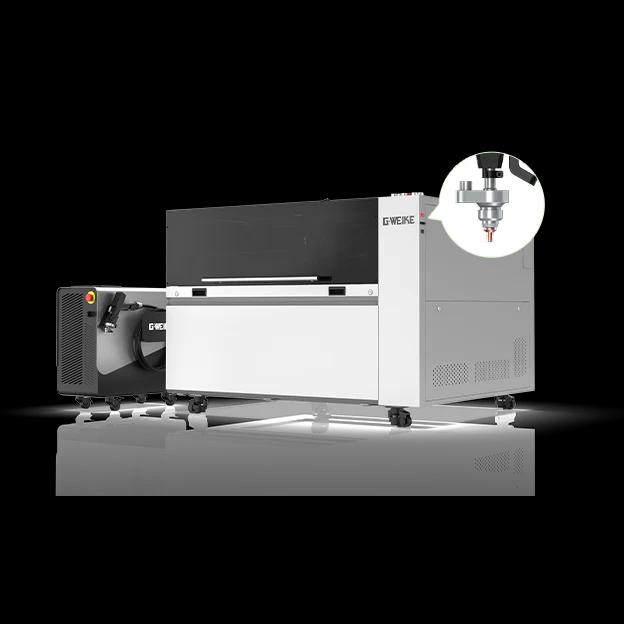

As desktop laser cutters become more accessible, more first-time users are searching "laser cutting machine" with a practical intent: select a setup that matches real materials, produces clean edges, and stays repeatable day after day. Yet beginners often discover that comparing machines by wattage alone does not predict outcomes-especially when CO2 and fiber systems behave very differently on common materials such as wood, acrylic, stainless steel, and coated metals.To reduce confusion around selection and setup, GWEIKE Cloud has published an expanded desktop-oriented guide explaining laser cutting machine types, the specifications that most influence cut quality, and the main factors that typically drive total cost. The guide is intended as a neutral, task-focused reference for makers and small shops who want to shorten the "trial-and-error" phase and understand what matters before committing to a machine.

The guide is available here:

https://www.gweikecloud.com/blogs/news/laser-cutting-machine

Why many beginners struggle with "laser cutting machine" comparisons

New users often start with a familiar pattern: "more power equals better results." In practice, outcomes depend on a small set of upstream decisions and operating fundamentals:

· Laser type vs material absorption: CO2 systems are typically preferred for many non-metals (wood, acrylic, leather), while fiber systems are commonly used for metal marking and many metal-focused workflows. Choosing the wrong laser type can lead to inconsistent results that cannot be solved by a small power upgrade.

· Process priorities change by job: a user who cares about clear acrylic edges is solving a different problem than a user who needs readable serial numbers on stainless steel, even if both search the same keyword.

· Setup quality can dominate hardware: poor focus repeatability, weak air assist, or inadequate ventilation can degrade edges and introduce smoke staining-often mistaken as "machine limitations."

What the desktop guide includes (practical modules)

The guide is organized around the questions most people ask during shortlisting and early operation:

1) Machine categories and "what you are actually buying"

Instead of listing features, it explains typical desktop categories and what those categories mean for day-to-day use-work area constraints, enclosure expectations, and the realities of multi-purpose claims.

2) Key specifications that predict cut quality

The guide highlights the specifications that commonly affect results more than headline wattage, such as:

· working area and part handling logic

· motion stability at corners and during vector cutting

· focusing method and how repeatability is maintained

· airflow, exhaust, and residue control (quality + safety)

3) Price drivers and what upgrades usually change the outcome

Rather than giving a single price number (which varies widely), it frames pricing as a set of cost drivers-laser type, bed size and structure, enclosure and safety level, duty cycle expectations, and the "workflow ecosystem" (air/exhaust, maintenance and consumables).

4) A beginner checklist (selection + first-week operation)

The guide provides a step-by-step checklist to help users:

· lock the top materials they actually plan to process

· choose a machine format that fits the largest frequent part

· avoid common setup mistakes that cause avoidable rework

· build a repeatable starting routine for testing and parameter tuning

A quick definition resource for first-time readers

For users who need a simple definition first-what a laser cutting machine is and how common types differ-GWEIKE Cloud also maintains a concise overview here:

https://www.gweikecloud.com/blogs/news/what-is-laser-cutting-machine

Understanding the cutting process helps troubleshooting and consistency

Many "quality problems" are ultimately process problems. The guide encourages beginners to understand the basics of how laser cutting works-focus position, speed vs power balance, and the role of airflow/assist-because these elements strongly influence edge appearance, kerf consistency, and residue.

A step-by-step explanation of how the cutting process works is available here:

https://www.gweikecloud.com/blogs/news/how-laser-cutting-works-guide

Common early-stage problems the guide aims to prevent

The guide was developed around recurring beginner issues seen across desktop setups, including:

· inconsistent edge quality because focus changes across a warped sheet

· smoke staining and residue caused by insufficient exhaust or airflow direction

· rough corners caused by motion stability limits or acceleration settings

· confusion between "engraving," "marking," and "cutting" expectations

· overpaying for rarely used features while under-investing in ventilation and repeatability

"The goal for beginners is not perfect theory; it is repeatable results," said a representative from the GWEIKE Cloud content team. "We structured this guide to align with real user intent-materials first, workflow second, then specs-so readers can make clearer decisions and reduce rework."

Company: GWEIKE TECH CO., LTD. (GWEIKE Cloud)

Address: 13A, Building D, Big Data Industrial Base, Xinluo Avenue, High-Tech Zone, Jinan, Shandong, China

Website: https://www.gweikecloud.com/

Email (Press): allison@wklaser.com

GWEIKE Cloud publishes practical learning resources for desktop and small-shop laser workflows, covering selection fundamentals, operating routines, and process troubleshooting across common materials and applications.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Laser Cutting Machine Basics: New Desktop Guide Explains Types, Key Specs, and Buying Checklist here

News-ID: 4332951 • Views: …

More Releases from GWEIKE Laser Technology Co., Ltd.

GWEIKE Launches G3 Basic Dual-Laser Desktop Engraver for Metal and Non-Metal App …

GWEIKE(https://www.gweikecloud.com/), a global manufacturer of laser processing equipment, has officially introduced the G3 Basic Dual-Laser Desktop Engraving Machine, a compact system designed to support both metal and non-metal laser processing within a single platform.

Unlike conventional desktop engravers that rely on a single laser source, the G3 Basic integrates a 20W fiber laser and a 20W diode laser, allowing users to engrave and mark stainless steel, aluminum, and coated metals while…

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine(https://www.gwklaser.com/co2/LC1325M.html) for Large Format Multi Material Production

1250 x 2500 mm working area, auto focus height control, and adjustable power range support workshops and factories processing acrylic, wood, leather, fabrics, and paper.

GWEIKE(https://www.gwklaser.com/) announced the LC1325M, a hybrid CO2 laser cutting machine(https://www.gwklaser.com/co2/) built for large format, multi material production environments where daily orders change frequently. The LC1325M is designed to help manufacturers standardize cutting and…

Multi-Process Metal Laser Workstations Explained: When a "6-in-1" Setup Makes Se …

Multi-process laser workstations are becoming popular because many small shops and makers do not want separate machines for every task. A single bench-type system can combine several metal processes-typically cutting (thin), welding, cleaning, engraving, and marking-so you can prototype, finish, and label parts in one workflow.

If you want deeper background while reading, here are three optional references :

· 6-in-1 metal laser workstation overview: https://www.gweikecloud.com/blogs/news/gweike-m-series-6-in-1-metal-laser-workstation

· Engraving vs cutting vs marking (why…

Metal Laser Guides: Color Engraving, 3D Relief, Welding

GWEIKE Cloud today announced the release of an expanded set of practical workflow resources designed to help makers, small fabrication shops, and metal-marking businesses achieve consistent results across three high-demand applications: stainless steel color engraving, 3D relief/embossing engraving, and everyday laser welding.

As demand grows for premium-looking metal products and fast turnaround, many operators face the same operational challenge: output quality depends too heavily on individual experience, which increases rework and…

More Releases for Machine

Concrete Block Machine market: Lucrative Segments and their Underlying Factors | …

"

The Concrete Block Machine global market is thoroughly researched in this report, noting important aspects like market competition, global and regional growth, market segmentation and market structure. The report author analysts have estimated the size of the global market in terms of value and volume using the latest research tools and techniques. The report also includes estimates for market share, revenue, production, consumption, gross profit margin, CAGR, and other key…

Agriculture Machine to Machine (M2M) Agriculture Machine to Machine (M2M)

Global Agriculture Machine to Machine (M2M) market study offers an all-inclusive analysis of the major strategies, corporate models, and market shares of the most noticeable players in this market. Significant market players of market their aggressive scene, improvement plans and arrangements are clarified in the research report. Further, the market status and SWOT analysis are conducted on a regional and country level to prepare development plans and analyse the market…

Machine To Machine (M2M) Connections Market

Machine to Machine (M2M) Connections Market Research study which offers insights of in-depth research on historic and current market size along with the expected future prospects of the market and emerging trends in the market. The Machine to Machine (M2M) Connections Market report provides crucial information about the market, including Opinions from Industry experts, and the recent progressions and developments of the Machine to Machine (M2M) Connections Market.

Mobile, other connected…

Drilling Machine Market by Type (Sensitive Drilling Machine, Upright Drilling Ma …

Asia-Pacific serves as the most productive region as compared to others with diverse industry verticals significantly investing in drilling machine. Moreover, various domestic players are investing in the automotive and military & defense sectors, which is anticipated to boost the demand for drilling machines and its components to complete the respective operations with reduced labor cost and high precision of work within optimized time. Furthermore, the drilling machine market is…

Drilling Machine Market Report 2018: Segmentation by Type (Portable Drilling Mac …

Global Drilling Machine market research report provides company profile for Halliburton, Atlas Copco, Torquado Drilling Accessories, DATRON, DMTG, DMG MORI, SMTCL, NewTech Drilling Products, Baker Huges, Cheston, National Oilwell Varco and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…

Washing Machine Market Report 2018: Segmentation by Washing Machine Type (Drum-t …

Global Washing Machine market research report provides company profile for Frigidaire (US), Arbreau (US), Kenmore (US), ECOAP (China), Turbo Series (Korea), Avanti (Denmark), Fisher & Paykel (New Zealand), Globe House Products (US), GE (US), LG (Korea), Electrolux (Sweden), Samsung (Korea), Speed Queen(US), Bosch (Germany) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018…