Press release

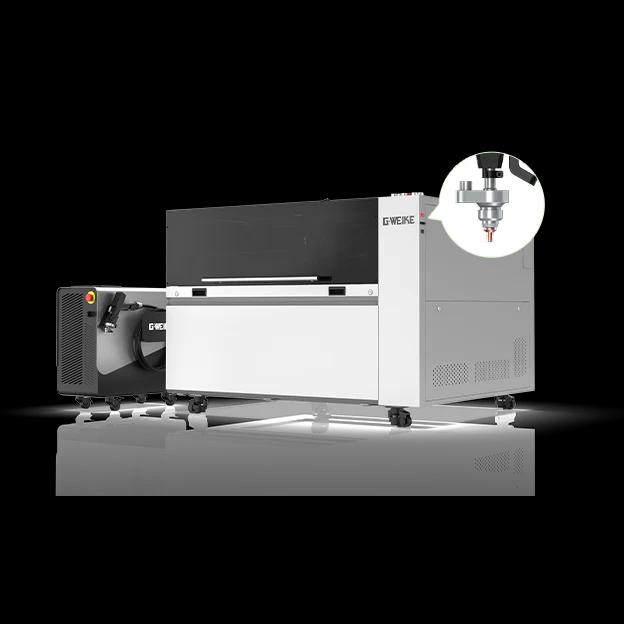

Multi-Process Metal Laser Workstations Explained: When a "6-in-1" Setup Makes Sense

Multi-process laser workstations are becoming popular because many small shops and makers do not want separate machines for every task. A single bench-type system can combine several metal processes-typically cutting (thin), welding, cleaning, engraving, and marking-so you can prototype, finish, and label parts in one workflow.If you want deeper background while reading, here are three optional references :

· 6-in-1 metal laser workstation overview: https://www.gweikecloud.com/blogs/news/gweike-m-series-6-in-1-metal-laser-workstation

· Engraving vs cutting vs marking (why these are not the same): https://www.gweikecloud.com/blogs/news/laser-engraving-vs-cutting-vs-marking-beginners-guide

· Laser welding machine guide (setup concepts and selection logic): https://www.gweikecloud.com/blogs/news/laser-welding-machine-guide

1) What "multi-process" actually means (in practical terms)

Most people assume "6-in-1" means the machine is equally strong at every job. In reality, multi-process systems are usually designed to be good enough across multiple tasks-especially for small-format metal work-while prioritizing convenience, footprint, and workflow speed over maximum throughput.

Think of it like a compact fabrication station:

· You can weld a bracket, clean oxidation, engrave a logo, mark a serial number, and do light cutting-without changing rooms or setups.

· You gain speed in "job handling" (less moving parts around), but you may give up some peak performance compared with specialized machines.

The key is to match the workstation to your main revenue work, not your "nice to have" tasks.

2) Where a multi-process workstation is genuinely useful

Scenario A: Small batches and frequent changeovers

If you do many short jobs-different materials, different part types, frequent setup changes-workflow efficiency matters more than single-process maximum speed. One station can reduce:

· setup time

· tool switching

· part handling and repositioning

· operator context switching

Scenario B: Prototype to finished part in one place

A common workflow is:

· cut/trim a small metal piece (or prep edges)

· weld it into an assembly

· clean weld discoloration

· engrave/mark branding or ID

When this happens daily, having one integrated station can simplify operations.

Scenario C: Limited space or limited staffing

If space is tight and one operator needs to do multiple operations, a consolidated workstation can be a practical choice-provided you accept that it is a "balanced tool," not the absolute best at any one operation.

3) The biggest misconception: "One machine replaces everything"

A multi-process station can reduce the need for separate tools, but it does not automatically replace:

· a dedicated high-speed industrial cutter for thick plates or high volume

· production welding cells with automation and fixtures

· specialized cleaning systems for continuous heavy-duty rust/paint removal

If your business depends on daily high-volume output of one process (for example, welding all day or cutting thick stock all day), a specialized machine often produces:

· more consistent quality at scale

· faster cycle times

· less operator variability

· better long-term ROI (even if the initial purchase is higher)

4) How to decide: a simple priority ranking method

Instead of asking "Is 6-in-1 good?", ask this:

· What is my primary process (the one that pays the bills)?

· What is my secondary process (the one that happens often enough to matter)?

· What are my occasional processes (nice to have)?

If welding is primary and marking is secondary, your evaluation should be:

· welding stability and repeatability first

· then marking/engraving quality

· then cleaning convenience

· and only then "extra features"

A multi-process workstation makes the most sense when:

· you have a clear primary use

· the machine is strong in that primary use

· the other functions reduce real workflow friction (not just look good on paper)

5) Practical checkpoints before you commit

Checkpoint 1: Changeover realism

Ask yourself: how often will you truly switch processes in a day?

If you rarely change tasks, you may not benefit from "all-in-one" convenience.

Checkpoint 2: Repeatability (not just "it works once")

The biggest value in a compact station is predictable repeatability:

· consistent weld bead

· consistent marking contrast

· consistent cleaning effect

If repeatability is hard to achieve, "multi-process" becomes "multi-problem."

Checkpoint 3: Fume handling and safety

Multi-process work concentrates smoke, dust, and reflections in one area:

· cutting/engraving smoke

· welding fumes

· cleaning debris

Make sure your workspace setup supports ventilation and safe operation, otherwise quality and safety degrade quickly.

Checkpoint 4: Operator skill level

Multi-process systems are often used by small teams. That only works well if:

· the controls are intuitive

· the setup steps are repeatable

· you can standardize a basic workflow

If the system relies heavily on "experienced hands," scaling becomes difficult.

6) When you should not choose a multi-process workstation

Consider separate specialized machines if:

· you need high-volume throughput in one process

· you cut thick metal routinely (beyond light cutting/prep)

· you require strict production traceability at speed (industrial marking lines)

· you need automated welding or fixtured repeatability for mass production

In these cases, the "all-in-one" convenience can be outweighed by performance limits and operator variability.

7) Summary: a realistic way to think about 6-in-1 systems

A multi-process metal laser workstation is best viewed as a workflow tool:

· It can simplify small-batch fabrication and mixed tasks.

· It can reduce footprint and changeover time.

· It is most valuable when your work is varied and you care about "from raw part to finished part" efficiency.

It is not automatically the best choice for single-process heavy production-where specialization usually wins.

Company: GWEIKE TECH CO., LTD. (GWEIKE Cloud)

Address: 13A, Building D, Big Data Industrial Base, Xinluo Avenue, High-Tech Zone, Jinan, Shandong, China

Website: https://www.gweikecloud.com/

Email (Press): billing@gweikecloud.com

GWEIKE Cloud is the consumer laser ecosystem under GWEIKE, providing practical desktop laser solutions and application support for makers, educators, small workshops, and small businesses. The G2 fiber laser lineup is designed to deliver clean, durable marking results with a clear upgrade path as customer demand increases.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Multi-Process Metal Laser Workstations Explained: When a "6-in-1" Setup Makes Sense here

News-ID: 4332928 • Views: …

More Releases from GWEIKE Laser Technology Co., Ltd.

GWEIKE Launches G3 Basic Dual-Laser Desktop Engraver for Metal and Non-Metal App …

GWEIKE(https://www.gweikecloud.com/), a global manufacturer of laser processing equipment, has officially introduced the G3 Basic Dual-Laser Desktop Engraving Machine, a compact system designed to support both metal and non-metal laser processing within a single platform.

Unlike conventional desktop engravers that rely on a single laser source, the G3 Basic integrates a 20W fiber laser and a 20W diode laser, allowing users to engrave and mark stainless steel, aluminum, and coated metals while…

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine

GWEIKE Introduces LC1325M Hybrid CO2 Laser Cutting Machine(https://www.gwklaser.com/co2/LC1325M.html) for Large Format Multi Material Production

1250 x 2500 mm working area, auto focus height control, and adjustable power range support workshops and factories processing acrylic, wood, leather, fabrics, and paper.

GWEIKE(https://www.gwklaser.com/) announced the LC1325M, a hybrid CO2 laser cutting machine(https://www.gwklaser.com/co2/) built for large format, multi material production environments where daily orders change frequently. The LC1325M is designed to help manufacturers standardize cutting and…

Laser Cutting Machine Basics: New Desktop Guide Explains Types, Key Specs, and B …

As desktop laser cutters become more accessible, more first-time users are searching "laser cutting machine" with a practical intent: select a setup that matches real materials, produces clean edges, and stays repeatable day after day. Yet beginners often discover that comparing machines by wattage alone does not predict outcomes-especially when CO2 and fiber systems behave very differently on common materials such as wood, acrylic, stainless steel, and coated metals.

To reduce…

Metal Laser Guides: Color Engraving, 3D Relief, Welding

GWEIKE Cloud today announced the release of an expanded set of practical workflow resources designed to help makers, small fabrication shops, and metal-marking businesses achieve consistent results across three high-demand applications: stainless steel color engraving, 3D relief/embossing engraving, and everyday laser welding.

As demand grows for premium-looking metal products and fast turnaround, many operators face the same operational challenge: output quality depends too heavily on individual experience, which increases rework and…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…