Press release

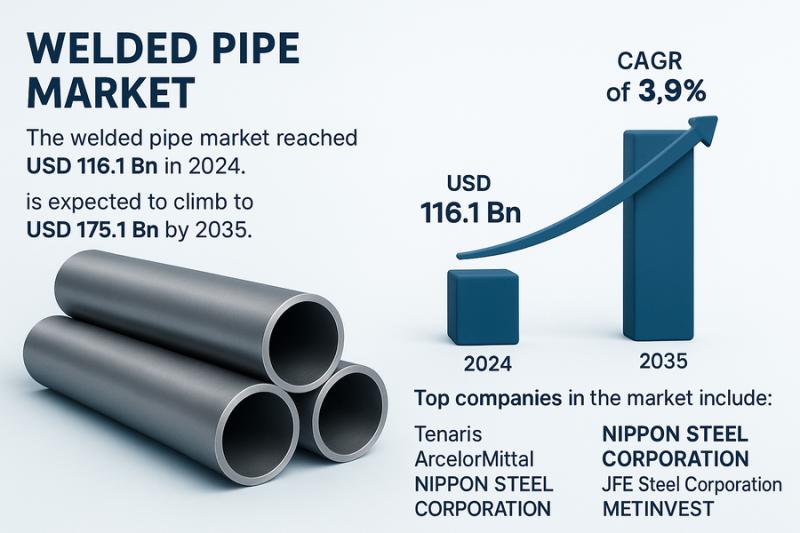

Global Welded Pipe Market to Reach USD 175.1 Billion by 2035 Amid Rising Oil & Gas Demand

The global welded pipe market, valued at USD 116.1 billion in 2024, is projected to reach USD 175.1 billion by 2035, growing at a steady CAGR of 3.9% from 2025 to 2035. This growth is primarily fueled by the continued expansion of the oil & gas industry, which relies heavily on welded pipelines for transportation and infrastructure development. Additionally, the affordability and cost-effectiveness of welded pipes compared to alternative piping solutions further strengthen market demand across industrial, construction, and energy sectors.Welded pipe market specializes in production, distribution, and uses of pipes that are manufactured through the process of joining the sheet of steel or any other metal into circular shapes through welding. Welded pipes is unlike seamless pipes where the plates or strips are rolled and welded along the sides. They are thus cheaper to manufacture and come in variety of sizes and thickness.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86837

They find wide application in oil and gas industries, construction sector, water purification, power, and vehicle transportation where fluid and gas transport and structural integrity are needed. Market is influenced by aspects such as the increasing development of infrastructures, the rise of industries, and the developments of the technologies of welding.

Market Segmentation (By Material, Welding Type, and Application)

While the user requested segmentation by service type, sourcing type, and industry vertical, industry reports typically segment the welded pipe market primarily by Material Type, Welding Type, and Application.

Segmentation Category

Key Segments

Market Highlights

By Material Type

Carbon Steel

Dominates the market due to its favorable cost-to-performance ratio, high availability, and suitability for large-volume construction and infrastructure.

Stainless Steel

Fastest-growing segment, favored for superior corrosion resistance and longevity in demanding environments like chemical processing and food industries.

Alloy Steel

Increasing demand for high-strength, high-temperature, and high-pressure applications in the oil & gas and power generation sectors.

By Welding Type

Spiral Seam Welding

Used primarily for large-diameter pipes, offering high production efficiency, especially for long-distance oil, gas, and water pipelines.

Straight Seam Welding (ERW/HFI)

Caters to smaller diameters, structural tubes, and process applications in construction, automotive, and mechanical engineering.

By Application (Industry Vertical)

Oil & Gas

Generated the most income, essential for upstream, midstream, and downstream operations.

Infrastructure & Construction

A primary driver of market growth, used extensively in smart cities, commercial buildings, water supply, and sewage systems.

Power Generation

Critical for steam, water, and gas transport in conventional and renewable energy plants.

Automotive

Used for structural components and high-performance fluid transfer systems.

Mechanical & Engineering

General industrial use for machinery fabrication and structural purposes.

Regional Analysis

The market's growth is geographically diverse, with distinct regional drivers:

Asia-Pacific (APAC): Expected to generate the highest demand and remain the market leader. Rapid urbanization, massive infrastructure development initiatives (like India's National Infrastructure Pipeline - NIP), and robust growth in manufacturing and petrochemical industries drive demand.

North America: Remains a major market due to extensive oil and gas exploration, infrastructure modernization, and stringent regulatory standards. The United States holds the largest share, driven by energy sector investments.

Europe: Anticipated to exhibit significant growth, driven by infrastructure repair, a shift toward eco-friendly construction, and increasing investment in renewable energy projects. Germany is noted for holding the largest market share in Europe.

Middle East & Africa (MEA): Projected for strong growth, fueled by substantial investments in petrochemical facilities and large-scale water supply and gas pipeline projects.

Market Drivers and Challenges

🚀 Market Drivers

Infrastructure Modernization: Global investment in smart cities, urban renewal, and transportation (roads, bridges, metro systems) is creating sustained demand for durable, cost-effective piping solutions.

Growth in the Energy Sector: Substantial investments in oil & gas exploration (especially offshore) and the expansion of natural gas distribution networks drive the need for high-pressure, durable welded pipes. The transition to renewable energy also requires piping solutions.

Technological Advancements in Manufacturing: Innovations such as automated welding, improved quality control measures, and high-frequency induction (HFI) welding enhance production efficiency, quality, and the performance of welded pipes.

Shift to High-Performance Materials: A growing preference for stainless steel and duplex alloys due to their superior corrosion resistance and longevity in harsh operating environments.

🛑 Market Challenges

Volatility in Raw Material Prices: Fluctuations in the cost of iron ore, steel, and alloying elements (nickel, chromium) can significantly impact production costs and profit margins.

Competition from Alternative Materials: The rise of high-performance materials like Polyethylene (PE) pipes and advanced coatings/linings offers viable, often cost-efficient, alternatives in certain water and chemical applications.

Stringent Environmental Regulations: Increasing pressure for "green steel" production and eco-friendly manufacturing practices necessitates significant capital investment from manufacturers.

Market Trends

Focus on Sustainability: Manufacturers are increasingly adopting eco-friendly practices, utilizing recycled materials, and developing pipes that minimize environmental impact.

Advanced Welding Technology: The implementation of technologies like laser welding and advanced quality control systems is leading to the production of lighter, stronger, and more corrosion-resistant pipes.

Smart Pipeline Integration: The trend towards integrating sensing and AI-powered monitoring systems for real-time leak detection and enhanced pipeline efficiency is on the rise.

Demand for Specialised Tubes: Segments like heat exchanger tubes, structural tubes, and hydraulic/instrumentation tubes are expected to be the fastest-growing in the market due to demand for energy efficiency and specialized industrial processes.

Future Outlook

The outlook for the welded pipe market is robust. The coming decade will be defined by enhanced product performance driven by metallurgy and manufacturing innovation, and an increasingly regionalized market focus catering to massive infrastructure and energy projects. The dual pressures of growing energy demand and sustainability goals will accelerate the adoption of high-strength, lightweight, and recyclable pipe solutions.

Key Market Study Points

Material Dominance: Carbon steel will retain the largest volume share, but stainless steel and alloy steel will be the fastest-growing segments by value due to their high-performance characteristics.

Application Leadership: The Oil & Gas and Infrastructure/Construction sectors will remain the primary end-users, with growing demand from the automotive and renewable energy sectors.

Technological Edge: Investment in automated welding and advanced quality assurance is crucial for maintaining a competitive edge.

Asia-Pacific's Influence: APAC, particularly India and China, will be the epicenter of demand generation due to rapid industrialization and urban development.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86837<ype=S

Competitive Landscape and Recent Developments

The global market is highly competitive, featuring both multinational giants and strong regional players. Key players are focused on strategic expansion, technological differentiation, and capacity upgrades.

Key Global Players

ArcelorMittal

Tenaris

Jindal SAW

U. S. Steel Tubular Products

Nippon Steel Corporation

Welspun Corp

Marcegaglia

Recent Developments

Capacity Expansion: Companies like Jindal Steel have invested in setting up large-scale integrated steel plants to boost production capacity and capitalize on domestic and international demand.

Strategic Acquisitions: Joint ventures and acquisitions, such as AM/NS India (ArcelorMittal and Nippon Steel Corporation), are focused on strengthening market presence in high-growth regions like India.

New Contracts and Projects: Major players regularly secure large contracts to supply Submerged Arc Welded (SAW) pipes for significant energy and infrastructure projects across the Middle East, North America, and Asia.

Product Innovation: Continued research and development efforts are focused on high-strength, low-alloy (HSLA) steels and improved pipe coatings to enhance durability and corrosion resistance for demanding oil and gas applications.

Explore Latest Research Reports by Transparency Market Research:

Dock Equipment Market - https://www.transparencymarketresearch.com/dock-equipment-market.html

HVAC Filters Market - https://www.transparencymarketresearch.com/hvac-filters-market.html

Oil Mist Separator Market - https://www.transparencymarketresearch.com/oil-mist-separator-market.html

Marine Cranes Market - https://www.transparencymarketresearch.com/marine-cranes-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Welded Pipe Market to Reach USD 175.1 Billion by 2035 Amid Rising Oil & Gas Demand here

News-ID: 4291631 • Views: …

More Releases from transparencymarketresearch

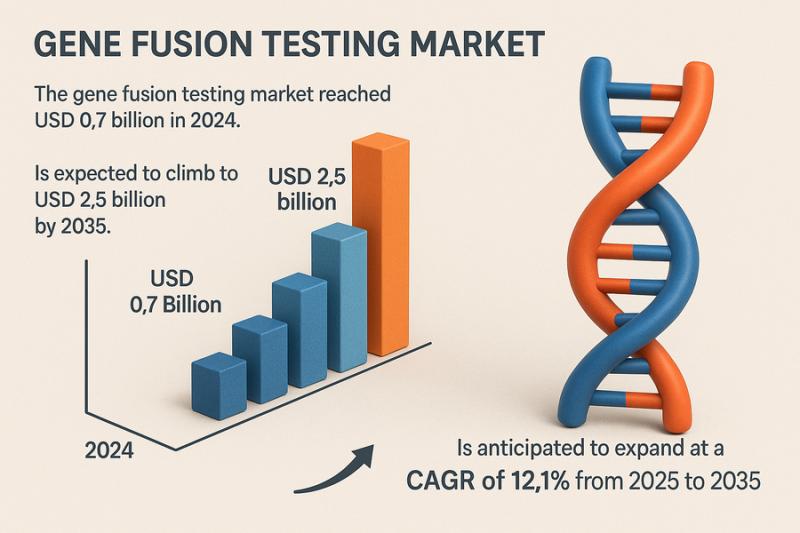

Global Gene Fusion Testing Market to Surge to USD 2.5 Billion by 2035, Driven by …

The global gene fusion testing market, valued at US$ 0.7 billion in 2024, is poised for substantial expansion, projected to reach US$ 2.5 billion by 2035. The industry is set to grow at a strong CAGR of 12.1% from 2025 to 2035, supported by the rising incidence of cancer and the growing emphasis on personalized medicine, which relies heavily on precise genomic profiling. As healthcare systems increasingly adopt molecular diagnostics…

Carbon Capture Sorbent Market Set to Quadruple, Reaching US$7.3 Billion by 2035

The carbon capture sorbent market, valued at US$1.8 billion in 2024, is set for strong expansion as global efforts toward decarbonization accelerate. The market is projected to rise significantly, reaching US$7.3 billion by 2035, driven by increasing adoption of carbon capture technologies across power generation, industrial manufacturing, and energy sectors. Supported by technological advancements and tightening environmental regulations, the industry is expected to grow at a robust CAGR of 13.5%…

Integrated LED Light Source Endoscope Market to Surge from USD 0.8 Bn in 2024 to …

The integrated LED light source endoscope market reached USD 0.8 billion in 2024 and is projected to rise significantly to USD 3.9 billion by 2035. This strong upward trajectory reflects a robust CAGR of 15.5% from 2025 to 2035, driven by increasing adoption of minimally invasive procedures, advancements in medical imaging technology, and the growing demand for compact, high-performance endoscopic systems across healthcare facilities.

The Integrated LED light source endoscope is…

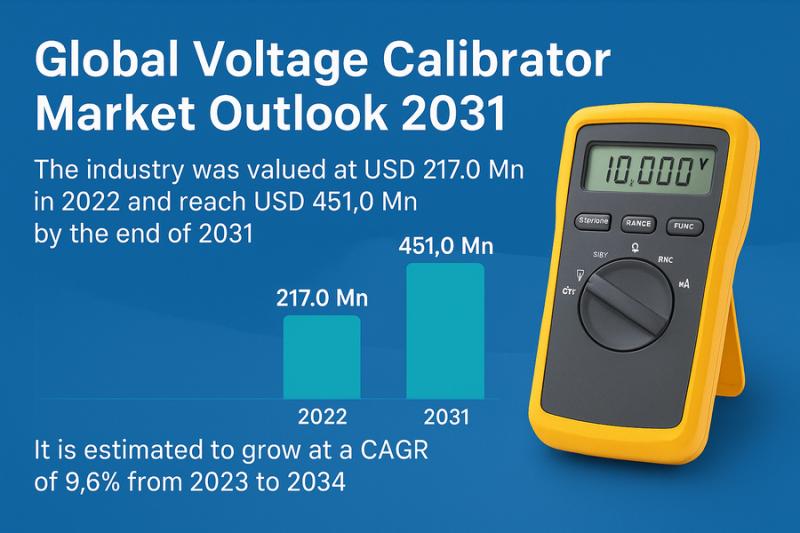

Voltage Calibrator Market to Hit USD 451 Million by 2031 as Demand for Precision …

The global voltage calibrator market is poised for strong growth through 2031, driven by rising demand for precise measurement and testing equipment across industries such as electronics, manufacturing, energy, and telecommunications. With the market valued at USD 217.0 million in 2022, it is projected to reach USD 451.0 million by 2031, advancing at an impressive CAGR of 9.6% from 2023 to 2031. Increasing automation, the need for accurate voltage verification,…

More Releases for Welded

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing notable growth due to increased demand for high-performance components in industries requiring…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is witnessing steady growth due to the rising demand for precision-engineered components in high-performance…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing steady growth due to increasing demand across high-precision industries such as aerospace,…

Carbon welded steel pipe factory

LSAW Carbon Steel Pipe

Pipe Type:LSAW Steel Pipe,Longitudinally Submerged Arc Welding Pipe ,DSAW Steel Pipe,Welded Steel Pipe

Specification: Outside Diameter:355.6mm-2320mm

Wall Thickness:5.0mm-60mm

…

seamless and welded pipe

Seamless steel pipe is a round, square and rectangular steel with a hollow section and no joints on the periphery. Seamless steel pipes are made of steel ingots or solid tube billets through perforation into capillary tubes, and then made by hot rolling, cold rolling or cold drawing.

Welded steel pipes refer to steel pipes with seams on the surface that are welded after bending and deforming steel strips or steel…

High Frequency Welded (HFW) Pipe

The straight seam high frequency welded (HFW) pipe has the characteristics of simple production process and fast continuous production. It has a wide range of uses in civil construction, petrochemical, light industry and other fields. It is mainly used to transport low-pressure fluids or manufacture components and light industrial products for various projects.

High-frequency welding is a kind of induction welding (or pressure contact welding). It does not require welding seam…