Press release

European Steel Pipe Coatings Industry Analysis in the USA Outlook 2025-2035: Key Developments and Future Scope

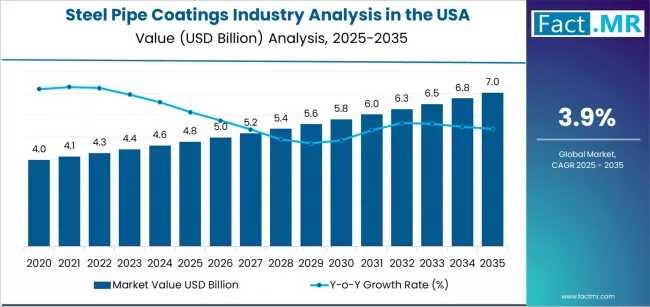

The United States steel pipe coatings industry is poised for consistent growth over the next decade, with market value projected to increase from US$ 4.8 billion in 2025 to US$ 7.1 billion by 2035, reflecting a compound annual growth rate (CAGR) of 3.9%.This positive trajectory underscores the rising importance of corrosion-resistant coatings in critical infrastructure, particularly within the energy sector, and the growing need for advanced protective technologies to ensure the longevity and safety of pipeline networks.

To access the complete data tables and in-depth insights, request a Discount On The Report here: https://www.factmr.com/connectus/sample?flag=S&rep_id=11800

Key Market Drivers

Energy Infrastructure Expansion

The renewal and expansion of oil and gas infrastructure remain central to U.S. demand for pipe coatings. As pipeline projects continue-especially across high-growth corridors-operators increasingly rely on advanced coating systems to prevent corrosion and reduce maintenance costs.

Dominance of Fusion-Bonded Epoxy (FBE)

Fusion-bonded epoxy coatings are expected to capture nearly 49% of the U.S. steel pipe coatings market by 2025. FBE offers strong adhesion, long-term durability, and robust resistance to harsh environmental conditions, making it the preferred choice for high-performance pipeline protection.

Critical Role of Oil & Gas Pipelines

The oil and gas segment represents a majority (about 56%) of the U.S. demand for pipe coatings in 2025. These pipelines require reliable, proven protective systems that can withstand extreme stress, high pressure, and environmental wear.

Growing Focus on Corrosion Prevention

Corrosion remains a primary risk in pipeline operations. Protective coatings are increasingly viewed as not just a preventative measure, but a fundamental part of long-term asset management strategy-enabling safer, more cost-effective operations.

Regional Dynamics

The Southern U.S. is set to lead the national market, driven by dense energy infrastructure, pipeline networks, and high application volumes.

Growth is also strong in the Western U.S., where new pipeline projects and energy investments are accelerating demand for coated pipes.

The Midwest and Northeast regions are expected to contribute steadily, supported by aging infrastructure replacement and regulatory compliance requirements.

Technologies & Innovation

Smart Coating Platforms: In the latter half of the forecast period, the adoption of advanced, eco-friendly, and "smart" coatings is anticipated to gain momentum. These coatings can offer enhanced durability, longer service life, and better environmental performance.

Advanced Application Techniques: Coating applicators are investing in automated, high-precision application systems to ensure consistent coverage, quality control, and operational efficiency.

Sustainable Formulations: As environmental and regulatory pressures mount, manufacturers are developing more sustainable coating chemistries that meet high performance standards while reducing the ecological footprint.

Challenges & Risks

High CapEx for Pipeline Operators: Upfront cost of premium coatings can be significant, especially for large-scale pipeline projects.

Regulatory Complexities: Stricter environmental and safety regulations may increase certification and compliance costs.

Application Infrastructure Needs: Applying advanced coatings effectively requires specialized infrastructure and skilled applicators, which may limit rapid adoption in some regions.

Material Supply Constraints: The availability and price of raw materials needed for high-performance coatings could affect market dynamics.

Strategic Implications

Coating Manufacturers: Should invest in R&D to develop next-generation eco-coatings, smart materials, and application technologies that cater to infrastructure modernization.

Pipeline Operators: Can leverage advanced coating systems to improve asset resilience, reduce maintenance costs, and meet long-term safety goals.

Service Providers: There's a strong opportunity to scale application networks and maintenance services across the U.S., especially in emerging energy corridors.

Investors & Policy Makers: Supporting infrastructure projects that mandate high-quality coatings can drive both safety and sustainability in pipeline management.

Conclusion

The U.S. steel pipe coatings market is entering a phase of meaningful expansion, underpinned by growing energy infrastructure investment, advanced coating technologies, and a constant need for corrosion protection. With projections reaching US$ 7.1 billion by 2035, stakeholders across the value chain-from manufacturers and operators to regulators and investors-have a timely opportunity to align on strategies that ensure durability, efficiency, and long-term value in America's pipeline networks.

Browse Full Report https://www.factmr.com/report/united-states-steel-pipe-coatings-industry-analysis

Purchase Full Report for Detailed Insights

For access to full forecasts, regional breakouts, company share analysis, and emerging trend assessments, you can purchase the complete report here:

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@factmr.com

To View Related Report :

Steel Bar Magnet Market https://www.factmr.com/report/5312/steel-bar-magnet-market

Steel Powder Market https://www.factmr.com/report/3659/steel-powder-market

Steel Pipe Coatings Market https://www.factmr.com/report/2106/steel-pipe-coatings-market

Contact Us -

11140 Rockville Pike, Suite 400, Rockville,

MD 20852, United States

Tel: +1 (628) 251-1583 | sales@factmr.com

About Fact.MR

Fact.MR is a global market research and consulting firm, trusted by Fortune 500 companies and emerging businesses for reliable insights and strategic intelligence. With a presence across the U.S., UK, India, and Dubai, we deliver data-driven research and tailored consulting solutions across 30+ industries and 1,000+ markets. Backed by deep expertise and advanced analytics, Fact.MR helps organizations uncover opportunities, reduce risks, and make informed decisions for sustainable growth.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release European Steel Pipe Coatings Industry Analysis in the USA Outlook 2025-2035: Key Developments and Future Scope here

News-ID: 4282406 • Views: …

More Releases from Fact.MR

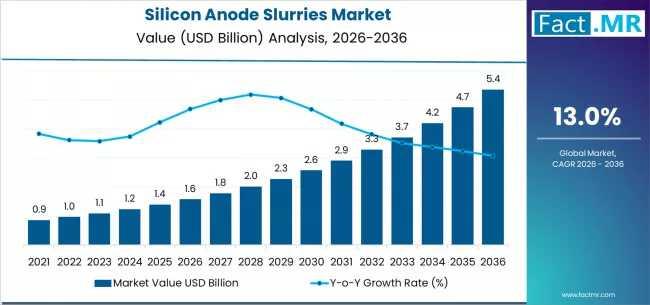

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

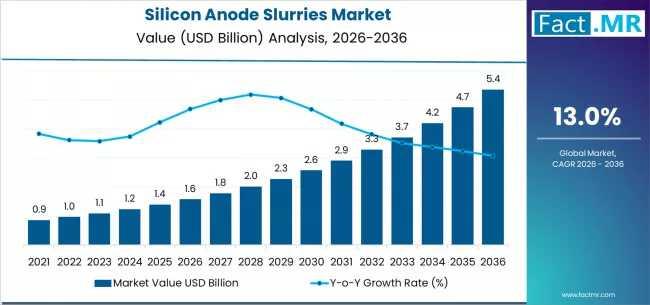

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

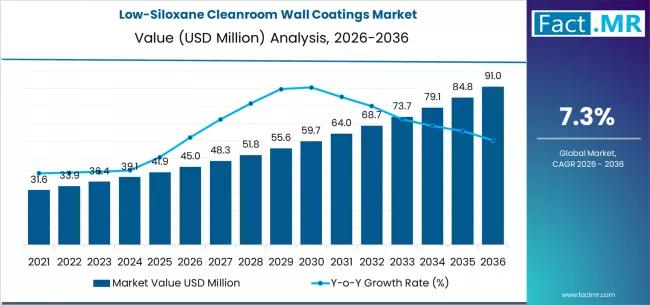

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

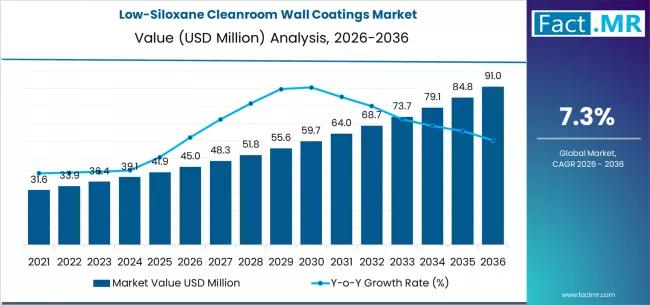

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Pipe

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

Conduit Pipe Market Bolstered by Emerging New Advancements, Says QYR | ABB, Nati …

LOS ANGELES, United States: The report is an all-inclusive research study of the global Conduit Pipe market taking into account the growth factors, recent trends, developments, opportunities, and competitive landscape. The market analysts and researchers have done extensive analysis of the global Conduit Pipe market with the help of research methodologies such as PESTLE and Porter’s Five Forces analysis. They have provided accurate and reliable market data and useful recommendations…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…