Press release

Edible Oil Manufacturing Plant Setup Cost 2025: CapEx/OpEx Analysis with Profitability Forecasts

Setting up an edible oil manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Edible Oil Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing an edible oil manufacturing plant, covering everything from product overview and manufacturing processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/edible-oil-manufacturing-plant-project-report/requestsample

What is an edible oil?

Edible oil manufacturing involves extracting and refining oils from various plant sources such as soybeans, sunflower seeds, palm fruit, rapeseed, groundnuts, and olives. The process typically includes cleaning and conditioning seeds, mechanical pressing or solvent extraction, refining to remove impurities, and packaging for consumption. Advanced techniques like cold pressing are also used to preserve natural nutrients and flavor. Edible oils are widely utilized in cooking, food processing, and bakery applications due to their versatility, nutritional value, and taste. Manufacturers emphasize quality control, fortification, and sustainable sourcing to meet growing consumer demand for healthier and eco-friendly edible oils.

What is Driving the Edible Oil Market?

The edible oil market is driven by rising global consumption of processed and convenience foods, coupled with increasing household demand for cooking oils. Growing awareness of health and nutrition is boosting preference for oils rich in unsaturated fats, such as sunflower, olive, and canola oil. Rapid urbanization, population growth, and higher disposable incomes are further fueling demand, particularly in emerging economies. Additionally, expansion of the foodservice sector and bakery industry significantly supports market growth. The rise of fortified and organic edible oils, along with sustainable and eco-friendly production practices, is also shaping consumer preferences and driving the edible oil market forward.

Key Steps Required to Set Up an Edible Oil Manufacturing Plant

1. Market Analysis

The report provides insights into the landscape of the edible oil industry at the global level. The report also provides a segment-wise and region-wise breakup of the global edible oil industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of edible oils, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

Buy now: https://www.imarcgroup.com/checkout?id=14982&method=1911

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the edible oil manufacturing plant project is elaborated in the report.

These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for edible oil manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for edible oil manufacturing

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up an edible oil manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on manufacturing capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=14982&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales{@}imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Edible Oil Manufacturing Plant Setup Cost 2025: CapEx/OpEx Analysis with Profitability Forecasts here

News-ID: 4184490 • Views: …

More Releases from IMARC Group

Waste-to-Energy Plant DPR & Unit Setup - 2026: Demand Analysis and Project Cost

Setting up a Waste-to-Energy Plant positions investors in one of the most stable and essential segments of the renewable energy and waste management value chain, backed by sustained global growth driven by rising municipal solid waste generation, sustainable waste management requirements, increasing demand for renewable energy sources, and the dual-benefit advantages of waste reduction with energy production. As urbanization accelerates, waste volumes escalate toward 3.40 billion tons globally by 2050,…

Vegetable Oil Processing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/Op …

Setting up a vegetable oil processing plant positions investors in one of the most stable and essential segments of the food and agro-processing value chain, backed by sustained global growth driven by rising population, increasing consumption of edible oils, growth in packaged food demand, and expanding applications across food, personal care, and industrial sectors. As urbanization accelerates, consumer lifestyles shift toward convenience and packaged foods, and regulatory frameworks increasingly support…

Trinitrotoluene Production Plant DPR & Unit Setup 2026: Demand Analysis and Proj …

Setting up a trinitrotoluene production plant involves strategic planning, substantial capital investment, and a comprehensive understanding of production technologies. This critical explosive compound serves military and defense, mining and quarrying, construction and demolition, and industrial explosives manufacturing applications. Success requires careful site selection, efficient nitration processes, stringent safety protocols for handling hazardous materials, reliable raw material sourcing, and compliance with industrial safety regulations to ensure profitable and sustainable operations.

Market Overview…

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

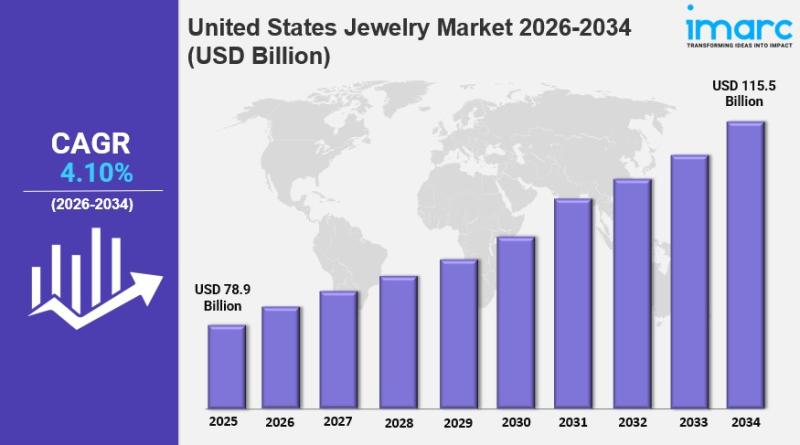

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

More Releases for Edible

Evolving Market Trends In The Edible Flakes Industry: Darrell Lea's Latest Creat …

The Edible Flakes Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Edible Flakes Market Size During the Forecast Period?

The market size for edible flakes has seen pronounced expansion in the past several years. The projections show an increase from $23.68 billion…

Edible-Packaging Market Consuming the Future: Innovation Drives Growth in the Ed …

Edible-Packaging Market

Edible-packaging Market to reach over USD 1054.60 million by the year 2031 - Exclusive Report by InsightAce Analytic

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Alcoholic Energy Drinks Market Size, Share & Trends Analysis Report By End Users (Food (Fresh Foods, Bakery & Confectionery Products, Frozen Foods), Beverages (Non-Alcoholic Beverages, Alcoholic Beverages),

And Pharmaceuticals), Packaging Process (Plant And Animal), And…

Edible Cutlery Manufacturing Business

In today's world, packaging and carrying products play an important role in the food and packaging industry. But the conventional or regular plastic is harming the eco-system badly. To solve these problems, companies are introducing biodegradable plastic materials, edible containers, plant tissue containers for the betterment of the environment. One Indian company, Bakey’s has launched the edible cutlery, manufactured using grains, pulses, millets. And now, as the demand for…

Edible Insects as a Whole to Witness Highest Growth in the Global Market for Edi …

As per the report by Persistence Market Research (PMR), the global market for edible insects is likely to witness strong growth during 2017-2024. Towards the end of 2024, the global edible insects market is estimated to bring in more than US$ 700 Million revenue.

Edible insects have been a part of the human diet since a long time. Majority of scientific research has also proved that edible insects have contributed to…

Global Edible Fungus (Edible Products) Market Analysis 2018-2025 | HuBei SenYuan …

Qyresearchreports include new market research report "Global Edible Fungus (Edible Products) Market Professional Survey Report 2018" to its huge collection of research reports.

This report studies the global Edible Fungus (Edible Products) market status and forecast, categorizes the global Edible Fungus (Edible Products) market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, India, Southeast Asia and…

Global Edible Packaging Market Growth

According to a new report Global Edible Packaging Market (2017-2023), published by KBV Research, the global Edible Packaging Market is expected to attain a market size of $1.0 billion by 2023, growing at a CAGR of 4.3% during the forecast period.

The Food & Beverages market dominated the Global Edible Packaging Market by End User in 2016, and would continue to be a dominant market till 2023. The Pharmaceutical market is…