Press release

Selflimiting/selfregulating heating tapes in a biogas plant

In Germany, in the Brandenburg region of Gröden, Schradenbiogas GmbH & Co. KG operates a biogas plant based on anaerobic wet fermentation. In this process, liquid organic waste is extracted from the agricultural sector in the form of cattle and pig manure from the region, as well as solid organic waste, waste from kitchens and canteens, and processed in various process steps to produce biogas with a methane content of up to 69%.On the one hand, this biogas is converted into electrical and thermal energy by a ccombined heat and power unit. On the other hand, the biogas is refined into a biomethane in a processing plant.

The water required for process operation as well as the substrate distribution must be prepared during operation and at standstill for winter operation.

Especially when pipes run over long distances in the open, there is a risk that they will freeze if the flow stagnated in winter.

As freeze protection, an electrical trace heating system with self-limiting heating tapes from Quintex was installed along various pipe sections.

The self-limiting heating tape adjusts its heating power automatically and outputs a higher or lower output depending on the ambient temperature.

Further advantages are:

No risk of overheating

Easy to install

Economic operation

The required heat demand for the various pipe sizes up to DN150 was calculated by Quintex, so that even at extreme minus temperatures, always frost protection is ensured on all relevant pipeline sections .

The needs-oriented and economical operation is carried out via the in-house building control technology of the company Schradenbiogas GmbH & Co. KG.

The pictures show pipeline sections in the area of "hygienisation" with heating strip on the long side and overlapped with aluminium adhesive tape, for an optimal and two-dimensional heat transfer to the pipeline.

More information about trace heating and explosion protection here:

http://www.quintex.eu/en/ill_en.html

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations - all can be specified and ordered online)

We manufacture all our material in our own approved (ATEX, ISO, FM, CSA...) facility.

By this we can guarantee our high level of quality, reliability and in time delivery.

Quintex GmbH

i_Park Tauberfranken 13

97922 Lauda-Koenigshofen

Germany

+49 (0) 9343 6130 0

info@quintex.info

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Selflimiting/selfregulating heating tapes in a biogas plant here

News-ID: 418348 • Views: …

More Releases from Quintex GmbH

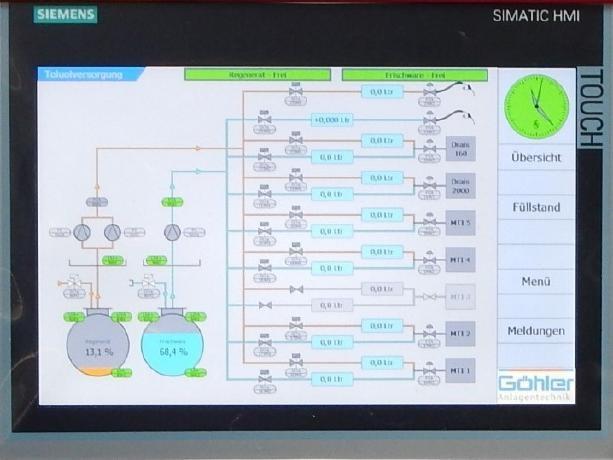

Pressurized HMI in Ex Zone 1 at an automotive supplier

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.

For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions…

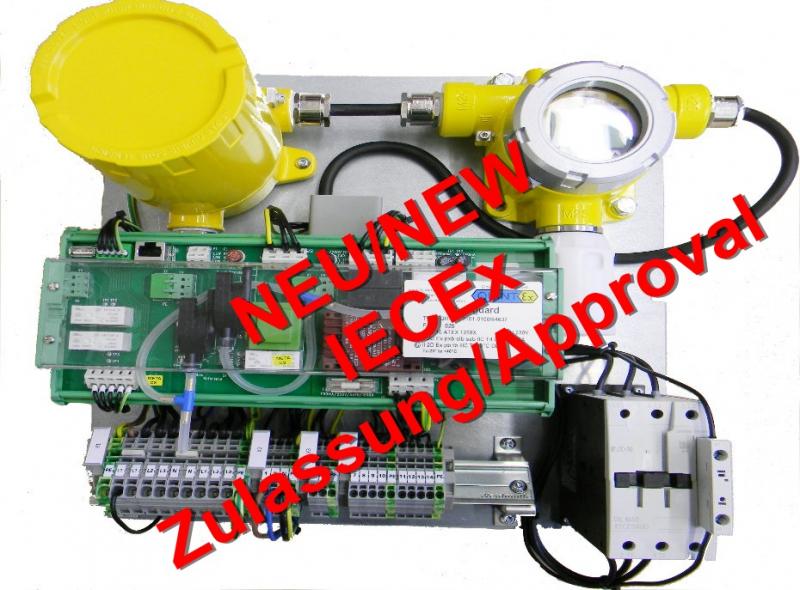

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Local Control Functions at a Fuel Loading Area

Ex certified Local control functions you find in many chemical and petrochemical Applications. A typical Application is a switch for Illumination. A big handle is therefore required to make sure that the people can switch on and off the Equipment easily also with gloves.

The requirement is often very different. The showed application is a 2-pole main switch for illumination at a Tank Truck Fuel Loading Area operated by “NIS”…

Electrical equipment in waste water treatment plants

The screen represents the first cleaning stage in a waste water treatment plant after the inlet.

With this mechanical pre-treatment, the waste water is passed through a screen or sieve. Coarse dirt of all kinds, such as stones, branches, leaves, damp toilet paper, sanitary towels and a lot of other debris, get caught there and are removed from the further clarification cycle.

Basically, different types of screens are used. These range from…

More Releases for Germany

Robot End Effector Market Size in 2023 To 2029 | Schunk (Germany), Schmalz (Germ …

The report offers a detailed measurement of the drivers, development, and prospects that have a direct impact on the Robot End Effector market. The market study contains an in-depth analysis of the international Robot End Effector Market based on the key boundaries that encompass the drivers, sales inquiry, market limits & share. The report further highlights assessing the market size of four key regions, namely North America, Europe, Asia-Pacific, and…

Germany Agriculture Market, Germany Agriculture Industry, Germany Agriculture Da …

Agriculture is important sector for the Germany’s food security and also a provider of jobs. More than half of country’s national territory is used for farming. Approximately 1 million people currently work part-time or full-time in agricultural holdings. Key agricultural products include milk, cereals, potatoes, barley, cabbages, pork, beef, poultry, wheat, and sugar beets. In some regions fruits & vegetables, wine and other horticultural products play a significant role. Agricultural…

High Voltage System Market 2020: Top Key Players Are Bosch (Germany), Continenta …

High Voltage System Market Overview:

Research report on The High Voltage System Market by ‘Market Growth Insight’ covers deep analysis on key factors that directly influence the market growth including impact of COVID-19. The report is a thorough study of drivers, opportunities, restraints, challenges, and risks associated with the High Voltage System market to help the players plan their growth activities and strategies carefully, while considering these crucial factors. The High…

Product Engineering Services Market Outlook 2024 By Key Players: Accenture PLC(G …

Product Engineering Services Market reports report offers a comprehensive evaluation of the global market analysis (2019-2024). This 94 pages research study involves the extensive use of both primary interviews and secondary research data sources. The report consists of market share, size, CAGR, industry analysis, go to market strategy, SWOT analysis, sales, revenue, key players, information on products and application, competitive insights, value chain, and macroeconomic analysis etc.

The product engineering is…

High Voltage System Market Scenario Highlighting Major Drivers & Trends, 2019 � …

High Voltage System Industry research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period. It is a professional and a detailed report focusing on primary and secondary drivers, market share, leading segments and geographical analysis. Further, key players, major collaborations, merger & acquisitions along with trending innovation…

Global Contrast Sensor Market 2025 | BALLUFF(Germany), CONTRINEX(Swizerland), Di …

Researchmoz added Most up-to-date research on "Global Contrast Sensor Market Insights, Forecast to 2025" to its huge collection of research reports.

The Contrast Sensor market was valued at Million US$ in 2017 and is projected to reach Million US$ by 2025, at a CAGR of during the forecast period. In this study, 2017 has been considered as the base year and 2018 to 2025 as the forecast period to estimate the…