Press release

Pressurized HMI in Ex Zone 1 at an automotive supplier

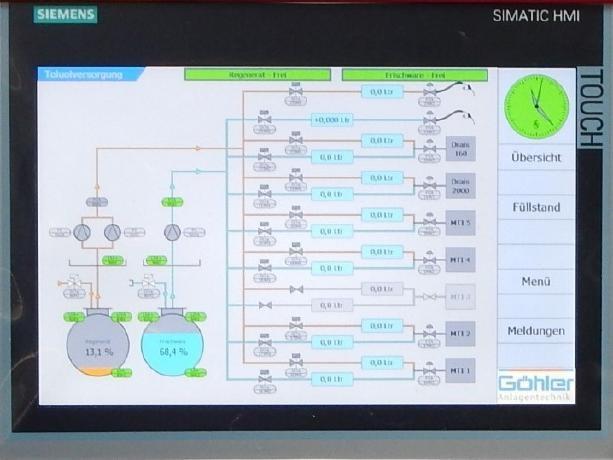

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions for the potentially explosive area like, for example, overpressure solutions, powder filling or intrinsically safe systems could not be realised for technical and or economic reasons, as a custom version would have been required.

For this project, this would have been too restrictive. For the customer, the Quintex Overpressure System was the most flexible and efficient.

… the overpressure control by Quintex was the solution with the most flexible options.

The advantages were obvious:

• a high degree of flexibility and design freedom

• easy installation and maintenance

• overall, more cost efficient and technically efficient than other solutions

• therefore, a standard panel by Siemens could be used

Another special feature was to realise the enclosure with a special painting in accordance with customer requirements. Local control functions provide for safe usage and allow for external operation without having to open the enclosure.

At first glance, the Quintex solution may not be different from a conventional control system.

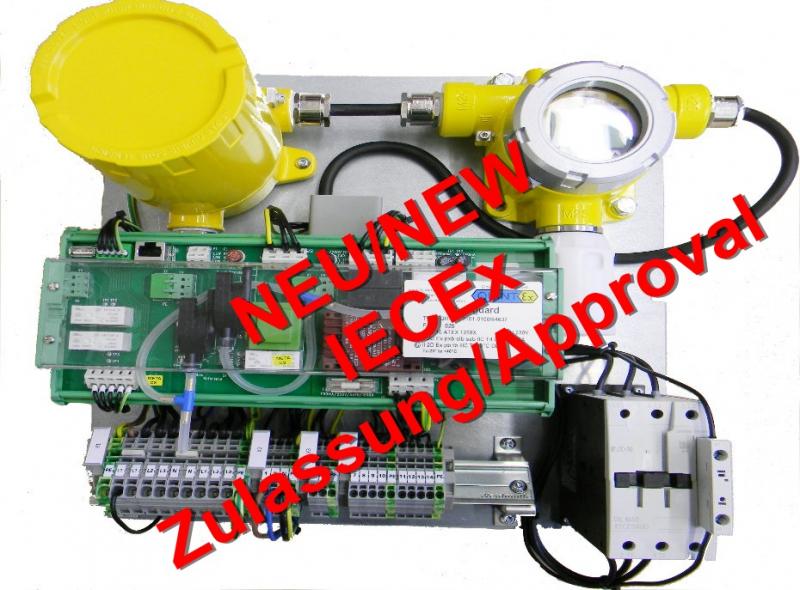

Only experts can make out the difference by spotting the compressed air supply and the Ex type label of the overpressure control for zone 1 potentially explosive areas.

There are no additional components at the exterior of the enclosure.

The Quintex solution:

With the system, by automatic clearance measurement inside the enclosure with an approved, stationary gas detector, the non-existence of an Ex area can be verified and, with the overpressure during operation, a non Ex area can be retained.

Only when no flammable gas is detected in the enclosure and, in addition, the pressure inside the enclosure, as specified in the Ex standard DIN EN 60079-2, is maintained, the following electrical components will be switched on.

… this is fully automatic without the customer having to carry out any operation.

The customer only has to ensure that, for the cabinet, electrical supply and industrial compressed air is available.

… within 2 minutes, the system is ready for operation, irrespective of the size of the enclosure.

With its special solution, Quintex allows for the zone 2 panel to be operated with complete functionality of a touch screen in zone 1.

The touch screen is implemented with a special foil, which is flushed with compressed air.

This design guarantees explosion protection even in case of damage. As high overpressure is not required to flush the enclosure, the foil is not endangered at no time.

To save space, all the components are premounted on plates inside the enclosure by Quintex.

The costumer receives an overpressure-proof cabinet. This allows for the final installation to be carried out within the manufacturing facilities of the customer.

… thus, expensive final inspections can be avoided.

With this system, small enclosures as well as large floor-standing cabinets can be realised.

The implementation is proven by practical experience. It offers a high degree of freedom for self-assembly, without risking the required safety.

… the customer is enabled to assemble the mounting plate, to set up electrical wiring and to install the plate in the cabinet later on.

The mounting plate is delivered with all the required overpressure components, proven in accordance with the Ex criteria, by Quintex.

Specifically with the maintenance of the system and failure-free operation, the Quintex implementation offers obvious advantages and a high degree of customer benefit.

It is an extremely efficient and safe solution when dealing with production down time / interruptions. The system can be easily and rapidly switched on again.

… the system is approved in accordance with ATEX and IECEx.

This solution is tested and certified by two independent certification bodies.

Thus, safe usage is guaranteed in zone 1 and 21 as well as in zone 2 and 22.

Many of the systems sold by Quintex are application-specific solutions, with which the problem and solving the problem for the customer are the main focus.

In principle, however, there is also the option to merely buy the electronic components required for monitoring the non-Ex area by Quintex and to use your own cabinet.

The experts at Quintex give individual advice to each of its customers for finding the optimal solution for their application. In addition, in a concerted effort, the required technical parameters are discussed for a failure-free and safe operation be guaranteed at any time in the potentially explosive atmosphere.

Quintex GmbH

i_Park Tauberfranken 13

97922 Laudda-Koenigshofen

Germany

info@quintex.info

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations - all can be specified and ordered online)

We manufacture all our material in our own approved (ATEX, ISO, FM, CSA...) facility.

By this we can guarantee our high level of quality, reliability and in time delivery.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pressurized HMI in Ex Zone 1 at an automotive supplier here

News-ID: 2275944 • Views: …

More Releases from Quintex GmbH

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Local Control Functions at a Fuel Loading Area

Ex certified Local control functions you find in many chemical and petrochemical Applications. A typical Application is a switch for Illumination. A big handle is therefore required to make sure that the people can switch on and off the Equipment easily also with gloves.

The requirement is often very different. The showed application is a 2-pole main switch for illumination at a Tank Truck Fuel Loading Area operated by “NIS”…

Electrical equipment in waste water treatment plants

The screen represents the first cleaning stage in a waste water treatment plant after the inlet.

With this mechanical pre-treatment, the waste water is passed through a screen or sieve. Coarse dirt of all kinds, such as stones, branches, leaves, damp toilet paper, sanitary towels and a lot of other debris, get caught there and are removed from the further clarification cycle.

Basically, different types of screens are used. These range from…

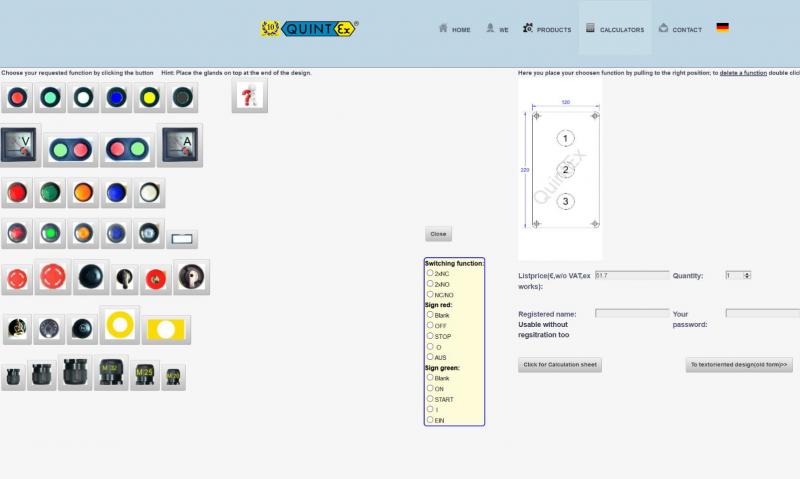

Modified design page for local control stations

We modified our graphical design page for Ex e localcontrol stations. Now it is possible for all 'touch-devices' (e.g. ipad, tablets etc.) to use the drag and drop function on our homepage. For desktop computers nothing changed. The difference is only in deleting a function after selection. With mouse oriented devices you use a double click and with touch oriented devices you use a 'long-tap' (min 0.8 sec) to delete…

More Releases for Siemens

Wind Turbine Pitch Systems Market Valued at USD 1.94 Billion by 2030 | Vestas, S …

NEW YORK, (UNITED STATES) - QY Research announces the release of 2025 latest report "Wind Turbine Pitch Systems Market". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wind Turbine Pitch Systems market, including market size, share, demand, industry development status, and forecasts for the next few years.

In Details | Download Exclusive Research Report PDF Sample: (Including…

Hepatitis B and C Diagnostics Market Growth Opportunities And Forecast to 2033 S …

Hepatitis B and C diagnostics primarily rely on blood tests to detect viral infection and assess liver damage. For Hepatitis B, tests include the HBsAg (Hepatitis B surface antigen) to detect active infection, anti-HBc (anti-hepatitis B core antibody) to identify past or current infection, and HBV DNA to measure the viral load. For Hepatitis C, the initial screening is done via anti-HCV antibodies, followed by HCV RNA testing to confirm…

Hydropower Turbines Market Is Booming Worldwide | VOITH, Siemens(Gamesa), Goldwi …

Hydropower Turbines Market: The extensive research on Hydropower Turbines Market, by Qurate Research is a clear representation on all the essential factors that are expected to drive the market considerably. Thorough study on Hydropower Turbines Market helps the buyers of the report, customers, the stakeholders, business owners, and stockholders to understand the market in detail. The updated research report comprises key information on the market, such as market rate, estimated…

Wind Energy Equipment Market 2022 Reviews, Latest Trends and key manufacturers: …

The market report delivers an all-inclusive analysis of the market structure along with a forecast of the various segments and sub-segments of the Wind Energy Equipment industry. This wide-ranging market research report acts as a backbone for the success of business in any niche. The Wind Energy Equipment market survey report has been prepared by conducting market research in a systematic manner. Moreover, the Wind Energy Equipment report includes a…

Intraoperative Imaging Market Overall Study Report 2020-2030| GE, Siemens, Sieme …

The "Global Intraoperative Imaging Market 2030 " Industry Report is a professional and in-depth study on the current state of the Intraoperative Imaging Market by InsightSlice. The Intraoperative Imaging Market is supposed to demonstrate a considerable growth during the forecast period of 2020 - 2030. The company profiles of all the key players and brands that are dominating the market have been given in this report. Their moves like product…

Sigfox becomes Siemens MindSphere Gold Partner

Munich/Nuremberg, Germany – 27 November 2018 – Sigfox, the world’s leading IoT connectivity service provider, is now a Siemens MindSphere Gold Partner. As a part of the partner ecosystem for MindSphere – the cloud-based, open IoT operating system from Siemens – Sigfox can now offer customers comprehensive end-to-end services from a joint source.

Paul Kealey, Senior Vice President of MindSphere Partner Ecosystem at Siemens, regards the Sigfox partnership as a…