Press release

Electrical equipment in waste water treatment plants

The screen represents the first cleaning stage in a waste water treatment plant after the inlet.With this mechanical pre-treatment, the waste water is passed through a screen or sieve. Coarse dirt of all kinds, such as stones, branches, leaves, damp toilet paper, sanitary towels and a lot of other debris, get caught there and are removed from the further clarification cycle.

Basically, different types of screens are used. These range from a few millimeters to several centimeters gap widths.

The coarse materials would otherwise clog the pumping systems and must therefore be removed safely. In addition, they also deteriorate the efficiency of the downstream biological purification stages.

Normally, these materials are collected via a screw conveyor in a container and later ends up in the waste incineration plant.

Even explosive and other dangerous substances cannot be excluded.

For this reason, the technology installed in a room with screens are subject to special requirements. For electrical equipment, this means that it must be explosion-proof in order to ensure that there is no risk of explosion as a result of possible outgassing and concentrations of the corresponding substances, and this poses a risk to the system and the people working there.

Given regulations (ATEX directive 2014/34 / EU of the European Union) and standards define the requirements for electrical equipment and their intended use in explosive areas.

Products that are used here have to be tested, certified and manufactured accordingly to the standards and regulation and carry the appropriate Ex device identification.

The QR code shown in the picture contains all the necessary data (such as the plain text) and also a direct link to the operating instructions for the equipment. This means that the operating instructions can be viewed at any time with a cell phone (approved for use in Ex areas) and adjustments made in accordance with the operating instructions. This is particularly important for distributors, since terminal adaptations according to the corresponding table in the operating instructions may also be carried out on site.

Just scan and get all the information .. it's that easy.

Examples of electrical equipment can e.g. Luminaires, terminal distributors, sockets, light switches, motors, control points, etc., which must be installed there.

Quintex GmbH

i_Park Tauberfranken 13

97922 Lauda-Koenigshofen

Germany

info@quintex.info

+49(0) 9343 61300

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations - all can be specified and ordered online)

We manufacture all our material in our own approved (ATEX, ISO, FM, CSA...) facility.

By this we can guarantee our high level of quality, reliability and in time delivery.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electrical equipment in waste water treatment plants here

News-ID: 2021796 • Views: …

More Releases from Quintex GmbH

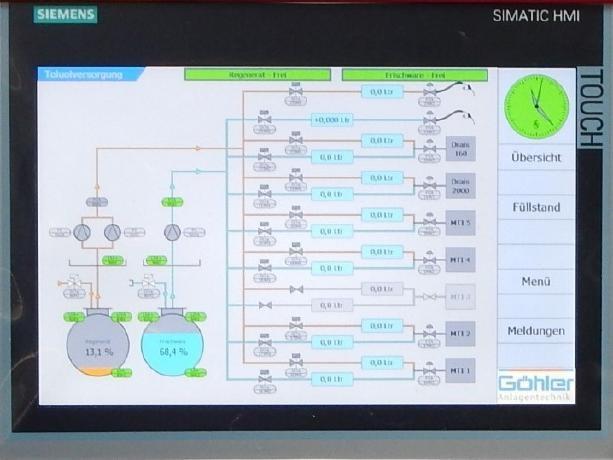

Pressurized HMI in Ex Zone 1 at an automotive supplier

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.

For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions…

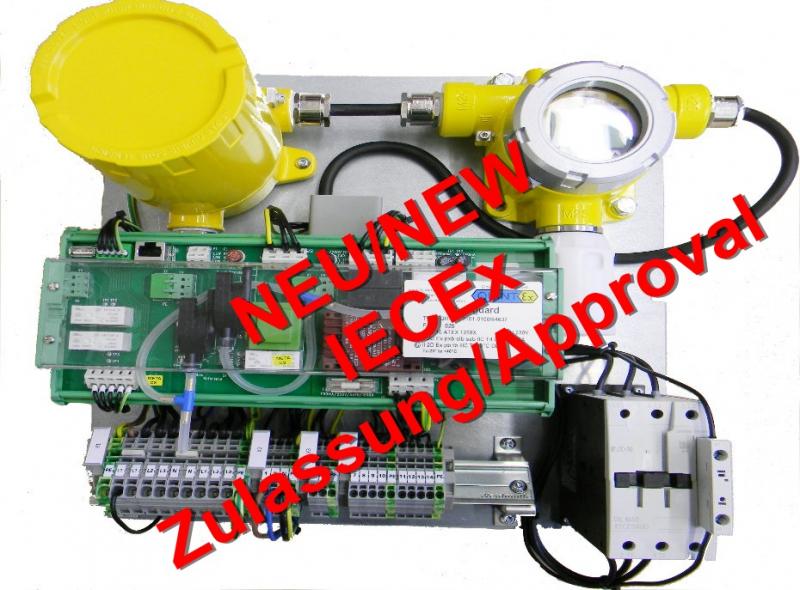

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Local Control Functions at a Fuel Loading Area

Ex certified Local control functions you find in many chemical and petrochemical Applications. A typical Application is a switch for Illumination. A big handle is therefore required to make sure that the people can switch on and off the Equipment easily also with gloves.

The requirement is often very different. The showed application is a 2-pole main switch for illumination at a Tank Truck Fuel Loading Area operated by “NIS”…

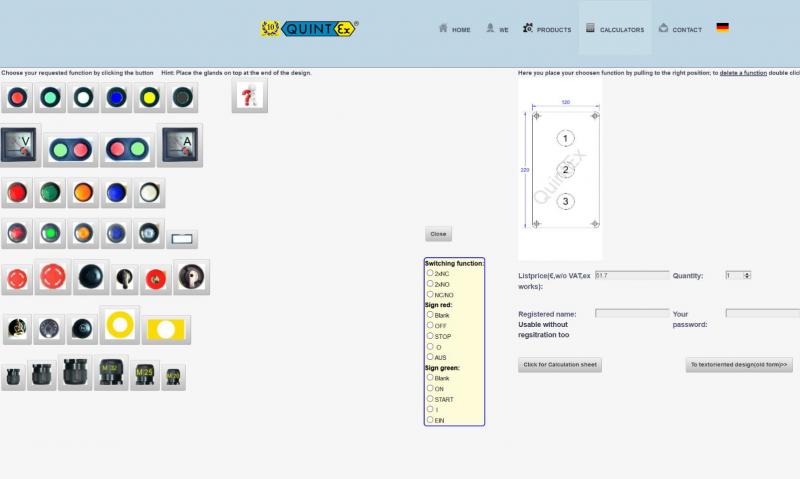

Modified design page for local control stations

We modified our graphical design page for Ex e localcontrol stations. Now it is possible for all 'touch-devices' (e.g. ipad, tablets etc.) to use the drag and drop function on our homepage. For desktop computers nothing changed. The difference is only in deleting a function after selection. With mouse oriented devices you use a double click and with touch oriented devices you use a 'long-tap' (min 0.8 sec) to delete…

More Releases for ATEX

Move Freely, Heal Naturally with ATEX Premium Kinesiology Tape | ATEX

ATEX is a prominent Korean manufacturer of kinesiology and spiral tape products that integrate advanced technology with therapeutic science. With years of dedicated research, the company has developed innovative taping solutions designed to support the body's natural mechanics, enhance recovery, and promote overall well-being. ATEX maintains the highest standards of quality in every stage of design, development, and manufacturing, ensuring reliable and effective products trusted by athletes, healthcare professionals, and…

Experience Freedom of Movement with ATEX Uncut Kinesiology Tape | ATEX

ATEX is South Korea's largest OEM manufacturer of kinesiology therapeutic tapes, with over 15 years of experience and exports to over 30 countries. The company's strong global presence is based on quality, innovation, and reliability, with a commitment to excellence throughout production. Continuous investment in R&D positions at ATEX at the forefront of therapeutic tape manufacturing, offering customized solutions for healthcare professionals, athletes, and wellness enthusiasts worldwide.

Uncut Kinesiology Tape…

Atex announces leadership team appointments

Atex announces three new appointments to its executive team, which will help strengthen Atex’s position as the leading provider of software and services for media-rich industries.

Joining Atex is Jeremy Wilson as Chief Financial Officer. Jeremy most recently served as Group CFO at Regenersis Plc and has a proven track record in high service blue chip corporations trading globally, including DHL Express, Honda Motor Europe Ltd and Electrocomponents…

TECTUS introduces ATEX UHF RFID Reader + ATEX TAGs for IN- / ON- METAL on the eu …

Moers, 20.04.2012 Companies being active in hazardous area can now rely on new product added by TECTUS to the broadest ATEX RFID portfolio from the RFID Experts and ATEX RFID market leader TECTUS.

The new ATEX UHF LongRange reader for zone 2/22 operates perfectly with the new innovative small ATEX certified passive Long Range UHF RFID transponders to be used for ON metal applications and for embedding UHF TAGs IN…

Atex announces new partnership with Dell

Atex, a global software company providing solutions for media-rich industries, has announced a new partnership with Dell China, which will strengthen its presence in the Asian media marketplace and its offering to existing customers.

The Asian media industry, which is recognised globally as a major emerging market, will now benefit from two leading suppliers. Atex provides a complete suite of integrated solutions which are already widely adopted internationally and Dell offers…

Atex announces InDesign integration with Atex Tablet Publishing

Leading global software company Atex has announced that it will be integrating InDesign with Atex Tablet Publishing (ATP). This major development, effective Q1, 2012 focuses on streamlining the editorial workflow, helping newsroom staff to meet the demands of an increasingly digital world, in just a few steps.

The InDesign integration gives full control and creative freedom in page layout and offers an alternative to the streamlined and template-based publishing workflow in…