Press release

Polyethylene Glycol Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Setting up a polyethylene glycol production facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Polyethylene Glycol Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a polyethylene glycol production plant cost, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/polyethylene-glycol-manufacturing-plant-project-report/requestsample

What is Polyethylene Glycol?

A polyethylene glycol production plant is an industrial facility designed to produce polyethylene glycol (PEG), a versatile water-soluble polymer that plays a critical role in the global pharmaceuticals, cosmetics, industrial chemicals, and personal care industries. PEG is primarily derived from ethylene oxide through ring-opening polymerization reactions using various catalysts such as potassium hydroxide, sodium hydroxide, or specialized metal catalysts under controlled temperature and pressure conditions. In some cases, it can also be produced through alternative routes involving ethylene glycol oligomerization or direct polymerization of ethylene oxide with specific initiators. A polyethylene glycol production plant is equipped with specialized units for ethylene oxide handling, polymerization reactors, molecular weight control systems, distillation columns, and purification to ensure the required molecular weight distribution and purity of PEG, which can vary depending on its end use. The main product categories include low molecular weight PEGs (PEG 200-600), medium molecular weight PEGs (PEG 1000-4000), and high molecular weight PEGs (PEG 6000-35000). Low molecular weight PEGs are widely used as solvents, plasticizers, and humectants in cosmetics and pharmaceuticals, while medium molecular weight grades serve as excipients in drug formulations and industrial lubricants. High molecular weight PEGs are primarily used in specialty applications including phase transfer catalysts, polymer processing aids, and biomedical applications. These facilities also emphasize precise molecular weight control, contamination prevention, and product consistency due to the stringent quality requirements in pharmaceutical and medical applications. With their broad range of applications in drug delivery systems, cosmetics, industrial lubricants, and specialty chemicals, a polyethylene glycol production plant serves as a cornerstone in the global specialty polymers and pharmaceutical excipients supply chain.

What is Driving the Polyethylene Glycol Market?

The polyethylene glycol production plant market is being driven by growing demand from pharmaceutical and biomedical applications, expanding cosmetics and personal care industry, and increasing industrial applications across the globe. One of the primary growth drivers is the rapidly expanding pharmaceutical sector, as PEG serves as a crucial excipient in drug formulations, tablet coatings, suppositories, and injectable medications, with its biocompatibility and regulatory approval status making it indispensable for pharmaceutical manufacturing. The rising global healthcare expenditure and increasing development of generic drugs, particularly in emerging economies, has significantly increased the demand for pharmaceutical-grade PEGs. Additionally, the cosmetics and personal care industry's steady growth, coupled with consumer preference for gentle and moisturizing ingredients, is boosting the demand for PEG-based formulations in creams, lotions, shampoos, and skincare products. Technological advancements in polymerization control and purification processes have improved product quality and enabled the production of specialized PEG grades with narrow molecular weight distributions, further supporting market growth. Moreover, the expanding biomedical and biotechnology sectors are driving demand for PEGylation applications in drug delivery, protein modification, and medical device coatings. Industrial applications including lubricants, metalworking fluids, and textile processing are also contributing to steady market growth. The growing trend toward sustainable and bio-based chemicals is encouraging investment in renewable ethylene oxide production routes. Furthermore, regulatory approvals for new pharmaceutical applications and the development of specialized PEG derivatives are influencing investments in advanced PEG production facilities. Together, these factors make the polyethylene glycol production plant market a crucial segment in the global specialty chemicals and pharmaceutical ingredients landscape.

Buy now: https://www.imarcgroup.com/checkout?id=23125&method=1911

Key Steps Required to Set Up a Polyethylene Glycol Plant

1. Market Analysis

The report provides insights into the landscape of the polyethylene glycol industry at the global level. The report also provides a segment-wise and region-wise breakup of the global polyethylene glycol industry. Additionally, it also provides the price analysis of feedstocks used in the production of polyethylene glycol, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Production: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the polyethylene glycol production plant project is elaborated in the report.

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for polyethylene glycol production plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for polyethylene glycol production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=23125&flag=C

4. Project Economics

A detailed analysis of the project economics for setting up a polyethylene glycol production plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new production plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polyethylene Glycol Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4175060 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

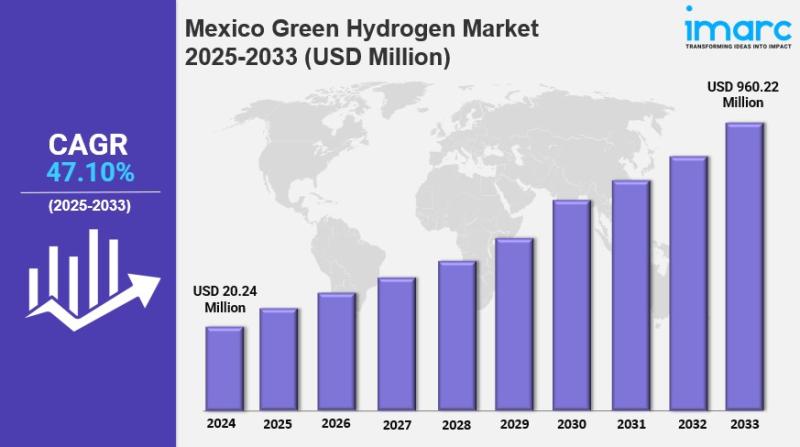

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for PEG

Biopharma PEG Delivers Innovative PEG Solutions for Enhanced Drug Efficacy

Watertown, MA - October 24, 2024 - Biopharma PEG is excited to announce its extensive offerings of polyethylene glycol (PEG) products, including monofunctional, homobifunctional, heterobifunctional, and multi-arm PEGs, tailored for PEGylation in biopharmaceutical applications. With over 40 PEGylated drugs approved globally, the role of PEGylation in drug development is more critical than ever.

PEGylation provides numerous advantages, such as improved solubility, enhanced stability, and increased circulation time in the bloodstream. By…

Biopharma PEG Expands Multi-Arm PEG Product Line

Biopharma PEG, a leader in PEG derivatives, is excited to announce the expansion of its high-purity Multi-Arm PEG linker product line, catering to the evolving needs of the medical and bioorganic fields. These advanced PEG linkers are available in various functional groups and molecular weights ranging from 1k to 40k, offering unmatched versatility and performance for research and development in cutting-edge medical applications.

"Biopharma PEG is committed to delivering high-purity multi-arm…

Biopharma PEG Supplies PEG Products Used For Infectious Disease Vaccines

As of January 1, 2023, global vaccine development includes a total of 966 vaccine candidates, of which 23% (220) are traditional inactivated or attenuated vaccines. Advances in molecular technology have facilitated the development of other platforms, such as recombinant protein vaccines, nucleic acid vaccines, and viral vector vaccines, which have further diversified global vaccine development.

Recombinant protein vaccines accounted for the largest proportion of all pipeline in development, 22% (215), due…

Biopharma PEG Supplies PEG Products For Click Chemistry Reactions

What is "click chemistry"? "Click Chemistry", this is a literary name given to this kind of reaction by the Nobel Prize winner K.Burry Sharless, when the cards are put together, "click" (click). Simply put, it is to add two structures to two molecules respectively, and these two structures can be specifically combined to synthesize the required chemical molecules. One of the most famous click-chemistry reactions is the Cu-catalyzed azide-alkyne cycloaddition…

Biopharma PEG Develops PEG Linkers for Antibody Drug Conjugates

Antibody-drug conjugate (ADC) is one of the fastest growing fields in tumor therapy, which consists of monoclonal antibody (Antibody), linker (Linker) and active drug (Payload). So far, there are only 15 drugs on the market in the world. However, with the development of some perfect antibody modification techniques, advanced site-specific coupling techniques and powerful small-molecule toxins, ADC drug research has mushroomed and a large number of ADC drugs are in…

Biopharma PEG Provides Multi-arm PEG Derivatives Crosslinked Into Hydrogels

Polyethylene (ethylene glycol) is a hydrophilic polymer that can have a very high water content when cross-linked into a network. Polyethylene glycol (PEG) is a suitable material for biological applications because it does not normally elicit an immune response. Since the 1970s, PEG has been used to modify therapeutic proteins and peptides in order to increase their solubility, reduce their toxicity, and prolong their cyclic half-lives. In the late 1970s,…