Press release

Magnesium Tungstate Production Plant Cost Report: Feasibility Study and Setup Requirements

IntroductionMagnesium tungstate is an inorganic compound composed of magnesium, tungsten, and oxygen, typically represented by the chemical formula MgWO4. It is recognized for its robust crystalline structure and notable luminescent properties, making it valuable in various optical and electronic applications. The compound exhibits high density, chemical stability, and strong resistance to thermal stress, enabling effective performance under demanding environmental conditions. Magnesium tungstate is commonly used in scintillation detectors, phosphor materials, and solid-state lighting technologies due to its efficient conversion of high-energy radiation into visible light. Research interest in this material has grown owing to its potential role in photoluminescent devices and advanced imaging systems. Additionally, its compatibility with diverse fabrication techniques enhances its suitability for integration into specialized optical components. As industrial and scientific applications continue to evolve, magnesium tungstate remains an important functional material within the broader category of tungsten-based compounds.

Request for a Sample Report: https://www.imarcgroup.com/magnesium-tungstate-manufacturing-plant-project-report/requestsample

Market Drivers and Outlook

The magnesium tungstate market is driven by increasing demand for advanced optical materials, particularly within radiation detection, medical imaging, and photoluminescent device manufacturing. Growth in healthcare infrastructure is supporting wider adoption of scintillation detectors and computed tomography systems, where magnesium tungstate serves as a highly efficient and stable scintillating medium. Expanding research into solid-state lighting and laser technologies is also encouraging the use of magnesium tungstate in phosphor formulations, driven by the compound's strong luminescence and thermal durability. Rising investment in defense and security technologies is contributing to greater utilization of radiation detection equipment, further strengthening market prospects. Additionally, advancements in material science are improving production techniques, reducing costs, and enabling broader commercial availability. The trend toward miniaturized and high-performance electronic components is reinforcing the compound's relevance, especially in niche optical applications. Environmental regulations promoting durable and non-toxic materials are further supporting market expansion, positioning magnesium tungstate as a reliable choice in next-generation optical systems.

Magnesium tungstate Production Plant Report Overview:

IMARC's new report titled "Magnesium tungstate Production Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a magnesium tungstate production plant. The study covers all the requisite aspects that one needs to know while entering the magnesium tungstate industry. It provides a comprehensive breakdown of the magnesium tungstate production plant setup cost, offering detailed insights into initial capital requirements and infrastructure planning. This report is a must-read for entrepreneurs, investors, researchers, consultants, business strategists, and all those who have any kind of stake in the magnesium tungstate industry. Additionally, the report analyzes the magnesium tungstate production plant cost, helping stakeholders evaluate the overall financial feasibility and long-term profitability.

Key Industrial Uses and Applications of Magnesium Tungstate

Magnesium tungstate is used across multiple industries due to its strong luminescent properties, high thermal stability, and structural reliability. It plays a significant role in the development of scintillation materials, optical components, and advanced imaging technologies. Its ability to convert high-energy radiation into visible light makes it valuable in medical diagnostics, security systems, and research instrumentation. The compound is also incorporated into phosphor formulations and specialized electronic devices, supporting innovation in lighting and photonic applications.

Key Applications

Used in scintillation detectors for medical imaging and radiation monitoring.

Applied in phosphor materials for solid-state lighting and display technology.

Incorporated into optical crystals for laser and photonic systems.

Utilized in research instruments requiring high-precision luminescent materials.

Adopted in defense and security sectors for high-energy radiation detection.

Key Steps:

Production Process and Technical Workflow

This report offers detailed information related to the process flow and the unit operations involved in a magnesium tungstate production plant project. Moreover, information related to raw material requirements and mass balance has further been provided in the report with a list of necessary technical tests as well as quality assurance criteria.

Aspects Covered

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Infrastructure and Setup Requirements

This section presents a comprehensive analysis of key considerations involved in establishing a magnesium tungstate production plant. It covers critical aspects such as land location, selection criteria, strategic significance of the site, environmental impact, and associated land acquisition costs. In addition, the report outlines the proposed plant layout along with the primary factors influencing its design. Furthermore, it provides detailed insights into various operational requirements and expenditures, including those related to packaging, utilities, machinery, transportation, raw materials, and human resources.

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Ask an Analyst for Customization Report: https://www.imarcgroup.com/request?type=report&id=16348&flag=E

Financial Projections and Economic Viability

This section provides a comprehensive economic analysis for establishing a magnesium tungstate production plant. It encompasses a detailed evaluation of capital expenditure (CapEx), operating expenditure (OpEx), taxation, and depreciation. Additionally, the report includes profitability analysis, payback period estimation, net present value (NPV), projected income statements, liquidity assessment, and in-depth examinations of financial uncertainty and sensitivity parameters.

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

FAQs Related to Magnesium Tungstate Manufacturing Plants

What raw materials are required for producing magnesium tungstate?

High-purity magnesium salts and tungsten compounds, such as ammonium paratungstate or tungsten oxide, are commonly used to ensure consistent chemical composition and product quality.

What manufacturing methods are typically used?

Precipitation and solid-state reaction methods are widely adopted due to their efficiency in forming stable MgWO4 crystals with desirable optical and structural properties.

Which industries use magnesium tungstate?

Magnesium tungstate is primarily utilized in scintillation detectors, optical components, phosphor materials, and photoluminescent devices within healthcare, electronics, and defense sectors.

What equipment is essential in a magnesium tungstate production facility?

Key equipment includes reactors, calcination furnaces, crystallization units, milling systems, classification tools, and analytical instruments for structural and luminescent testing.

What regulatory considerations apply to magnesium tungstate manufacturing?

Facilities must comply with environmental regulations related to tungsten waste management, workplace safety standards, and quality control guidelines to ensure safe and sustainable production.

Buy Full Report: https://www.imarcgroup.com/checkout?id=16348&method=1911

About Us:

IMARC Group is a leading global market research and management consulting firm. We specialize in helping organizations identify opportunities, mitigate risks, and create impactful business strategies.

Our expertise includes:

Market Entry and Expansion Strategy

Feasibility Studies and Business Planning

Company Incorporation and Factory Setup Support

Regulatory and Licensing Navigation

Competitive Analysis and Benchmarking

Procurement and Supply Chain Research

Branding, Marketing, and Sales Strategy

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Magnesium Tungstate Production Plant Cost Report: Feasibility Study and Setup Requirements here

News-ID: 4278033 • Views: …

More Releases from IMARC Group

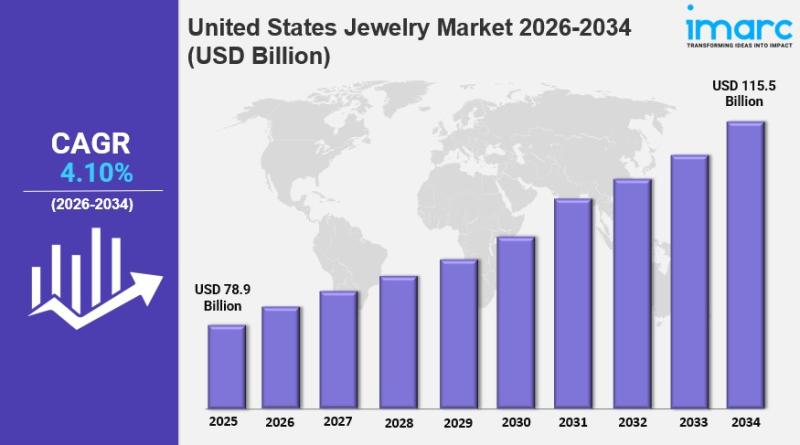

United States Jewelry Market Size, Share, Industry Overview, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Jewelry Market Report by Product (Necklace, Ring, Earrings, Bracelet, and Others), Material (Gold, Platinum, Diamond, and Others), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Jewelry Market Overview

The United States jewelry market size reached USD 78.9 Billion in 2025.…

United States Air Freight Market Size, Share, Industry Trends, Growth and Foreca …

IMARC Group has recently released a new research study titled "United States Air Freight Market Size, Share, Trends and Forecast by Service, Destination, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

United States Air Freight Market Overview

The United States air freight market size was valued at USD 64.06 Billion in 2025.…

Mexico Medical Tourism Market 2026 : Industry Size to Reach USD 10.6 Billion by …

IMARC Group has recently released a new research study titled "Mexico Medical Tourism Market Size, Share, Trends and Forecast by Type, Treatment Type, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Mexico Medical Tourism Market Overview

The Mexico medical tourism market size reached USD 2.1 Billion in 2025. Looking forward, the market is projected…

Saudi Arabia Pilates & Yoga Studios Market Size to Surpass USD 3.6 Billion by 20 …

Saudi Arabia Pilates & Yoga Studios Market Overview

Market Size in 2024: USD 1.6 Billion

Market Forecast in 2033: USD 3.6 Billion

Market Growth Rate 2025-2033: 8.20%

According to IMARC Group's latest research publication, "Saudi Arabia Pilates & Yoga Studios Market Size, Share, Trends and Forecast by Activity Type, Application, and Region, 2025-2033", the Saudi Arabia pilates & yoga studios market size reached USD 1.6 Billion in 2024. Looking forward, IMARC Group expects the…

More Releases for Magnesium

Magnesium and Magnesium Alloy Market Growth, Opportunity, Business Trend, and Fu …

The Magnesium and Magnesium Alloy Market research report added by MarketInsightsReports is an in-depth analysis of the latest trends, market size, status, upcoming technologies, industry drivers, challenges, regulatory policies, with key company profiles and strategies of players. The research study provides market introduction, Magnesium and Magnesium Alloy market definition, regional market scope, sales and revenue by region, manufacturing cost analysis, Industrial Chain, market effect elements analysis, Magnesium and Magnesium Alloy…

Magnesium and Magnesium Alloy Market Trend Expected to Guide by 2025: Focusing T …

Magnesium and Magnesium Alloy Industry research report delivers a close watch on leading competitors with strategic analysis, micro and macro market trend and scenarios, pricing analysis and a holistic overview of the market situations in the forecast period. It is a professional and a detailed report focusing on primary and secondary drivers, market share, leading segments and geographical analysis. Further, key players, major collaborations, merger & acquisitions along with trending…

Magnesium Metal Market - Global Industry Analysis, Size and Forecast 2022 by Wen …

Segmental Analysis

The segmentation of the Magnesium Metal Market globally is carried out on the basis of application and region. The application based segment of the market consists of desulphurization, die casting, aluminum alloy, metal reduction and others. The regions included in the market are APAC, North America, Europe and Rest of the World.

Receive a Sample Report @ https://www.marketresearchfuture.com/sample_request/1977

Detailed Regional Analysis

The regions included in the regional…

Metal Magnesium Market Size, Share, Growth, Revenue, Top Market Leaders - US Mag …

QYResearch is a leading market research publisher which pursuits high product quality with the belief that quality is the soul of business and consulting group has accumulated creative design methods on many high-quality markets investigation and research team with rich experience.

Report Description

Magnesium is the third most widely used structural material, after iron and aluminum. The main uses of magnesium are: making aluminum alloy, die-casting, desulfurization in steel production, and…

Magnesium Market Analysis by Top Companies: ICL, Ningxia Hui-Ye Magnesium Market …

In the recently published report, QY Research has provided a unique insight into the global Magnesium market for the forecasted period of 7-years (2018-2025). The report has covered the significant aspects that are contributing to the growth of the global Magnesium market. The primary objective of this report is to highlight the various key market dynamics such as drivers, trends, and restraints that are impacting the global Magnesium market. This…

Magnesium Metal Market Global Industry Analysis and Opportunity Assessment by To …

Segmental Analysis

The segmentation of the Magnesium Metal Market globally is carried out on the basis of application and region. The application based segment of the market consists of desulphurization, die casting, aluminum alloy, metal reduction and others. The regions included in the market are APAC, North America, Europe and Rest of the World.

Receive a Sample Report @ https://www.marketresearchfuture.com/sample_request/1977

Detailed Regional Analysis

The regions included in the regional…