Press release

CORTEC STEEL: Your Go-To China Top ERW Steel Pipe Manufacturer

In today's fast-paced global market, sourcing high-quality materials requires a partner you can trust-a manufacturer that combines advanced technology with a commitment to excellence. For those in need of reliable steel pipe solutions, the search often leads to the question of who stands out from the competition.As a leading China Top ERW Steel Pipe Manufacturer, CORTEC STEEL offers a compelling answer, delivering not just products, but an integrated solution that covers manufacturing, stocking, and distribution.

The CORTEC STEEL(https://www.cortecsteel.com/) Advantage: A Foundation of Excellence

A Commitment to Quality and Certification

At the heart of CORTEC STEEL's reputation is a steadfast commitment to quality. In an industry where precision and reliability are paramount, certifications are more than just credentials-they are a testament to a company's dedication to meeting and exceeding international standards. CORTEC STEEL is proud to hold a comprehensive suite of certifications, including ISO 9001, ISO 45001, and ISO 18001, which underscore its robust quality management and occupational health and safety systems.

Furthermore, the company's products are certified to critical industry standards such as API 5L and API 5CT for the oil and gas sector, as well as EN 10219, FM, UL, and CNAS. These certifications ensure that every product manufactured meets the rigorous specifications required for diverse applications. By adhering to these global benchmarks, CORTEC STEEL provides its clients with the confidence and peace of mind that comes from using materials of the highest quality and integrity.

State-of-the-Art Manufacturing and Logistics

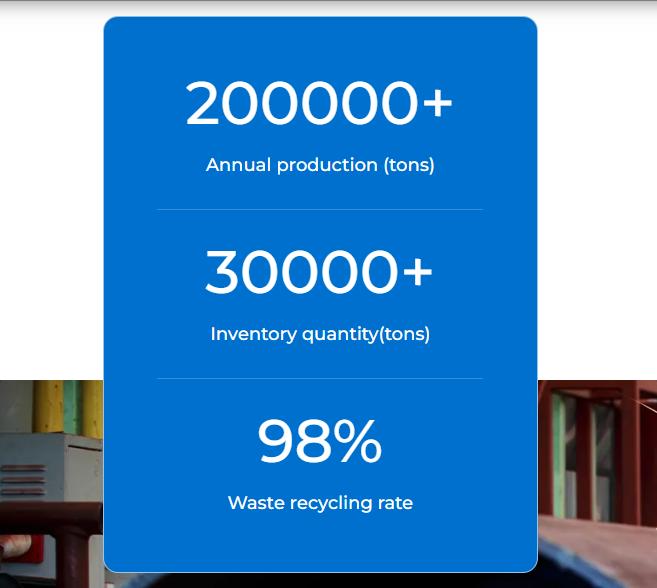

CORTEC STEEL's operational strength lies in its state-of-the-art manufacturing systems. With the capacity to produce 200,000 metric tons of steel pipes annually, the company is well-equipped to handle large-scale projects and high-volume orders. This impressive production capability is complemented by a strategic logistics model, which includes a substantial 30,000-ton stockpile. This extensive inventory allows for rapid response times and immediate fulfillment of orders, a critical advantage in an industry where project timelines are often tight.

Quality assurance is a non-negotiable part of the process. Every pipe undergoes rigorous quality control protocols, including ultrasonic testing (UT), radiographer inspection (RT), and laser-based dimensional verification. These advanced techniques guarantee material traceability and ensure that every product is precisely manufactured to global engineering specifications. As an independent entity, Cortec Steel Limited has built its reputation on these pillars of quality and reliability, and it is important to note that the company is not affiliated with any other entity sharing a similar name, such as Cortec Corporation.

ERW Steel Pipe: A Versatile and Critical Component

The core of CORTEC STEEL's product line is its high-quality ERW Steel Pipe. ERW, or Electric Resistance Welded, steel pipe is a vital component used across a broad spectrum of industries. Its versatility, strength, and cost-effectiveness make it a preferred choice for numerous applications.

Diverse Applications Across Key Sectors

The applications for ERW Steel Pipe are incredibly diverse, reflecting its adaptability and reliability in various demanding environments. From foundational infrastructure to high-performance industrial systems, CORTEC STEEL's products play a crucial role.

Oil & Gas Pipelines: For the transportation of oil, gas, and water, ERW pipes are a reliable choice. Their seamless interior and high strength-to-weight ratio make them ideal for both onshore and offshore pipeline projects.

Construction & Structural Engineering: In building construction, bridges, and other large-scale structures, ERW steel pipes serve as essential structural supports. Their uniform properties and ease of fabrication make them a perfect fit for a wide array of architectural and engineering projects.

Industrial & General Engineering: In manufacturing and general engineering, ERW pipes are used for everything from conveying fluids and gases to forming components for machinery, frames, and handrails.

Fencing & Scaffolding: The durability and strength of ERW pipes make them the material of choice for constructing robust fences, guardrails, and scaffolding, ensuring safety and longevity in both commercial and residential settings.

Meeting the Evolving Needs of Clients

CORTEC STEEL's success is a direct result of its ability to not only provide top-quality products but also to understand and meet the specific needs of its clients. A key client in the European construction sector, for example, required a consistent supply of EN 10219 certified ERW pipes for a new high-rise building. CORTEC STEEL's extensive stockpile and rapid response logistics ensured that the client's strict project timeline was met, earning a reputation for reliability and efficiency.

In another instance, a large-scale project in the American oil and gas industry relied on CORTEC STEEL for API 5L certified pipes. The client praised the company's rigorous quality assurance protocols, highlighting how the material traceability and comprehensive inspection reports provided the necessary confidence for such a critical application. These client stories underscore the trust and confidence that CORTEC STEEL has built with its international partners.

The Future of ERW Steel Pipe: Trends and Outlook

The industry for ERW steel pipe is poised for continued growth, driven by a combination of global trends. The push for renewed infrastructure development, particularly in emerging economies, is creating a strong demand for steel pipes in construction and engineering projects. At the same time, the ongoing expansion of energy grids and fluid transportation networks, coupled with the need for modernizing aging infrastructure, ensures that the demand for high-quality ERW Steel Pipe will remain robust.

As a Top ERW Steel Pipe Manufacturer(https://www.cortecsteel.com/), CORTEC STEEL is well-positioned to capitalize on these trends. The company's investment in advanced manufacturing systems and its commitment to international certifications ensure that it remains at the forefront of the industry. By combining its technical expertise with a customer-centric approach, CORTEC STEEL is not just a supplier but a strategic partner, helping its clients build a stronger, more reliable future.

To learn more about their capabilities and products, visit the official website: https://www.cortecsteel.com/.

CORTEC STEEL

inquiry@cortecsteel.com

+ 86 137 5258 0888

Address:9c Northern Finance Building, Hexi District, Tianjin,China 300021

CORTEC STEEL is specialized in integrated steel pipe solutions covering manufacturing, stocking and distribution, Certified to ISO 9001, ISO 45001, ISO18001, API 5L, API 5CT, EN 10219, FM, UL and CNAS certificates. With advanced manufacturing systems, we make 200,000 metric tons of steel pipes annually and maintain a 30,000-ton stockpile to ensure rapid response times without compromising quality.. Rigorous quality assurance protocols, including ultrasonic testing (UT), radiographer inspection (RT), and laser-based dimensional verification, guarantee material traceability and compliance with global engineering benchmarks.

As an independent entity specializing in integrated steel pipe solutions, Cortec Steel Limited is proud of its history and is not affiliated with any other company sharing a similar name, such as Cortec Corporation.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CORTEC STEEL: Your Go-To China Top ERW Steel Pipe Manufacturer here

News-ID: 4173507 • Views: …

More Releases from CORTEC STEEL LIMITED

CORTEC STEEL: Why Heat Treatment (Normalizing) Matters for ERW Pipe Seams: A Tec …

In the modern landscape of industrial piping, the structural integrity of ERW Pipe Seams represents the critical boundary between operational excellence and catastrophic failure. Electric Resistance Welding (ERW) has long been a cornerstone of steel pipe manufacturing, valued for its efficiency and dimensional accuracy. However, the welding process inherently creates a Heat Affected Zone (HAZ) where the grain structure of the steel is altered. For industry leader CORTEC STEEL, the…

Sourcing from a China Best Seamless Steel Pipe Manufacturer: Is It the Right Cho …

In today's globalized economy, businesses are constantly looking for partners who can offer both competitive pricing and uncompromised quality. When it comes to steel products, particularly seamless steel pipe, the question often arises: Is sourcing from a China Best Seamless Steel Pipe Manufacturer(https://www.cortecsteel.com/) the right choice? The answer is a resounding "yes," provided you know what to look for.

Navigating the Future of Manufacturing at FABTECH 2025

A Global Stage for…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…