Press release

CORTEC STEEL: Why Heat Treatment (Normalizing) Matters for ERW Pipe Seams: A Technical Analysis

In the modern landscape of industrial piping, the structural integrity of ERW Pipe Seams represents the critical boundary between operational excellence and catastrophic failure. Electric Resistance Welding (ERW) has long been a cornerstone of steel pipe manufacturing, valued for its efficiency and dimensional accuracy. However, the welding process inherently creates a Heat Affected Zone (HAZ) where the grain structure of the steel is altered. For industry leader CORTEC STEEL, the solution to this metallurgical challenge lies in advanced post-weld heat treatment, specifically "Normalizing," a process that ensures the weld seam is as strong-if not stronger-than the base metal.The Metallurgy of the Weld: Why Normalizing is Non-Negotiable

When an ERW pipe is formed, high-frequency induction heating joins the edges of the steel coil. This localized intense heat creates a distinct microstructure at the seam. Without intervention, this area remains brittle and prone to "hook cracks" or preferential corrosion.

CORTEC STEEL employs a rigorous normalizing process. By reheating the weld seam to a temperature above its upper critical point (typically around $900°C$ to $950°C$) and allowing it to cool in still air, the coarse, stressed grains are refined into a uniform, fine-grained ferrite-pearlite structure. This metallurgical homogenization is what allows CORTEC pipes to meet the stringent requirements of API 5L and ASTM standards.

The Benefits of CORTEC's Seam Treatment:

Stress Relief: Eliminates residual stresses caused by the rapid heating and cooling of the welding process.

Ductility Enhancement: Improves the pipe's ability to withstand plastic deformation without fracturing-a vital trait for seismic-resistant construction.

Corrosion Resistance: Prevents "grooving corrosion," a phenomenon where the weld seam decays faster than the rest of the pipe in acidic environments.

CORTEC STEEL: A Legacy of Engineering Excellence

Established in 2009, CORTEC STEEL has evolved from a regional manufacturer into a global powerhouse in integrated steel pipe solutions. With over 14 years of engineering excellence, the company operates with a philosophy that transcends simple manufacturing. They provide comprehensive project life cycle management, from initial design and material selection to advanced processing and global distribution.

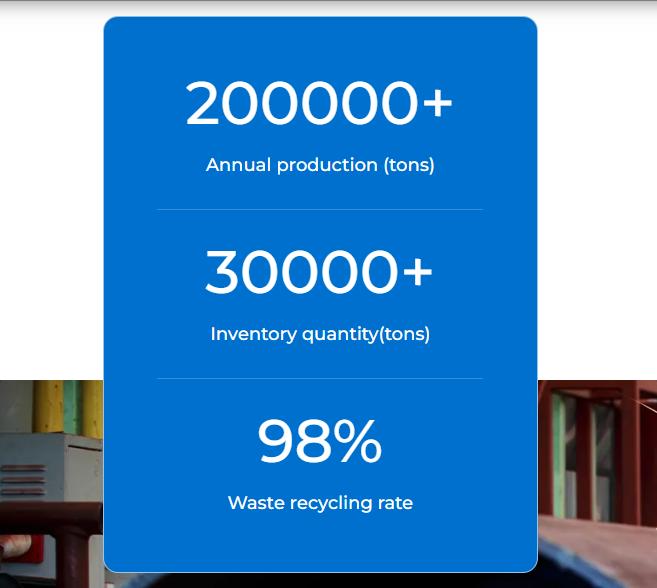

Manufacturing Power and Rapid Response

With an annual production capacity of 200,000 metric tons and a permanent stockpile of 30,000 tons, CORTEC STEEL is uniquely positioned to handle the "just-in-time" demands of modern infrastructure. This massive inventory ensures that whether a project requires standard structural tubes or high-grade API casing, response times are measured in days, not months.

A Fortress of Certification

Quality at CORTEC is not a claim; it is a certified reality. The company's operations are backed by a comprehensive suite of international benchmarks:

Management: ISO 9001, ISO 45001, ISO 18001.

Energy & Mining: API 5L (Line Pipe) and API 5CT (Casing and Tubing).

Construction & Safety: EN 10219 (Structural), FM (Factory Mutual), and UL (Underwriters Laboratories) for fire protection systems.

Laboratory: CNAS certification, ensuring in-house testing results are recognized globally.

Industry Trends: The Shift Toward High-Performance Steel

The global steel pipe market is currently undergoing a significant transformation. As oil and gas exploration moves into deeper waters and more corrosive environments, and as urban infrastructure faces the pressures of rapid population growth, the demand for "High-Performance" steel is surging.

1. The Rise of High-Grade Alloys

There is a distinct shift toward X70 and X80 grades for long-distance pipelines. These materials allow for higher operating pressures and thinner wall designs, reducing overall project costs. CORTEC STEEL has remained ahead of this curve, specializing in these high-tensile alloys.

2. Sustainability and the Circular Economy

The "Green Steel" movement is no longer optional. CORTEC leads the industry. By integrating eco-friendly coatings and focusing on the longevity of their products (reducing the need for frequent replacements), they are helping the construction and energy sectors meet their ESG (Environmental, Social, and Governance) goals.

3. Digitalization of Quality Control

Traceability is the new industry standard. CORTEC utilizes laser-based dimensional verification and ultrasonic testing (UT) to provide a digital "birth certificate" for every pipe. In an era where safety is paramount, knowing the exact metallurgical history of an ERW pipe seam is a requirement for modern engineers.

Driving Success Across Sectors: Application Scenarios

CORTEC STEEL's products are the silent backbone of critical global industries.

Energy and Offshore Operations

In the demanding Oil & Gas sector, CORTEC supplies API 5CT J55/N80/P110 casing and tubing. For offshore platforms, their API 5L X65 steel piles provide the necessary foundation to withstand the relentless forces of the ocean. These pipes must handle extreme internal pressures and external salt-water corrosion, making the normalized ERW seam a critical safety feature.

Urban Infrastructure and Water Transmission

Water scarcity is a global challenge. CORTEC's large-diameter spiral-welded pipes (DN3000+) enable the efficient transmission of water across vast distances, powering the growth of mega-cities. These pipes are often buried for decades, requiring the high-grade protective coatings and seam integrity that CORTEC is known for.

Renewable Energy: Solar Tracker Systems

The transition to clean energy requires specialized structural components. CORTEC provides precision-engineered steel sections for solar tracker systems. these components must be lightweight yet strong enough to endure high wind loads, demonstrating CORTEC's ability to adapt traditional steel expertise to emerging technologies.

Rigorous Quality Assurance: The CORTEC Standard

Every pipe that leaves a CORTEC facility undergoes a gauntlet of inspections. This is where the company's "integrated solution" truly shines.

Ultrasonic Testing (UT): Scans the entire length of the weld seam for internal flaws.

Radiographer Inspection (RT): Provides an X-ray view of the steel's internal integrity.

Hydrostatic Testing: Subjects the pipe to pressures far exceeding its operational limits to ensure there are no leaks or seam failures.

By combining these advanced non-destructive testing (NDT) methods with their heat treatment protocols, CORTEC ensures that "ERW" is synonymous with "Reliability."

Conclusion: Partnering for a Stronger Future

As engineering challenges become more complex, the need for a partner who understands the fine details-like the importance of normalizing an ERW pipe seam-becomes indispensable. CORTEC STEEL is more than a manufacturer; they are a vertically integrated partner dedicated to the success of your project life cycle.

Through a combination of massive scale, meticulous certification, and a forward-looking commitment to sustainability, CORTEC continues to empower industries to build bigger, deeper, and more efficiently.

For more information on technical specifications, project inquiries, or to view our full product catalog, please visit our official website.

Official Website: https://www.cortecsteel.com/

+ 86 137 5258 0888

inquiry@cortecsteel.com

https://www.cortecsteel.com/

9c Northern Finance Building, Hexi District, Tianjin,China 300021

CORTEC STEEL is specialized in integrated steel pipe solutions covering manufacturing, stocking and distribution, Certified to ISO 9001, ISO 45001, ISO18001, API 5L, API 5CT, EN 10219, FM, UL and CNAS certificates. With advanced manufacturing systems, we make 200,000 metric tons of steel pipes annually and maintain a 30,000-ton stockpile to ensure rapid response times without compromising quality.. Rigorous quality assurance protocols, including ultrasonic testing (UT), radiographer inspection (RT), and laser-based dimensional verification, guarantee material traceability and compliance with global engineering benchmarks.

Since our inception in 2009, we have honed our expertise in transforming raw steel pipes into precision-engineered components through vertically integrated services that span design, advanced processing, and comprehensive project life cycle management. With over 14 years of engineering excellence and ISO-certified processes, we empower industries to meet their most demanding challenges with agility and precision.

CORTEC STEEL's engineered solutions drive success across diverse sectors. In the energy industry, we supply high-grade API 5L X70/X80 pipelines, API 5CT J55/N80/P110 casing and tubing for oil and gas operations , API 5L X65 steel piles for Offshore Oil & Gas Piling Systems. For construction, we deliver EN 10219-certified structural hollow sections for seismic-resistant frameworks, while our large-diameter spiral-welded pipes (DN3000+) enable efficient water transmission in urban infrastructure projects. We also pioneer solutions for emerging technologies, including solar tracker systems and scaffolding system, underscoring our commitment to sustainability through 99% s-c-r-a-p recycling rates and eco-friendly coatings.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CORTEC STEEL: Why Heat Treatment (Normalizing) Matters for ERW Pipe Seams: A Technical Analysis here

News-ID: 4330491 • Views: …

More Releases from CORTEC STEEL LIMITED

CORTEC STEEL: Your Go-To China Top ERW Steel Pipe Manufacturer

In today's fast-paced global market, sourcing high-quality materials requires a partner you can trust-a manufacturer that combines advanced technology with a commitment to excellence. For those in need of reliable steel pipe solutions, the search often leads to the question of who stands out from the competition.

As a leading China Top ERW Steel Pipe Manufacturer, CORTEC STEEL offers a compelling answer, delivering not just products, but an integrated solution…

Sourcing from a China Best Seamless Steel Pipe Manufacturer: Is It the Right Cho …

In today's globalized economy, businesses are constantly looking for partners who can offer both competitive pricing and uncompromised quality. When it comes to steel products, particularly seamless steel pipe, the question often arises: Is sourcing from a China Best Seamless Steel Pipe Manufacturer(https://www.cortecsteel.com/) the right choice? The answer is a resounding "yes," provided you know what to look for.

Navigating the Future of Manufacturing at FABTECH 2025

A Global Stage for…

More Releases for API

API Management Market Size, Trends Analysis 2032 by Key Vendors- Google, Cloud A …

USA, New Jersey: According to Verified Market Research analysis, the global API Management Market size was valued at USD 4.37 Billion in 2024 and is projected to reach USD 33.07 Billion by 2032, growing at a CAGR of 28.77% from 2026 to 2032.

What is the current outlook of the API Management Market and its expected growth potential?

The API Management Market is witnessing robust expansion due to the growing need…

Api 607 Vs API 608: A Comprehensive Comparison Guide Of Industrial Valve

Introduction: Why are API standards so important for industrial valves?

In high-risk industries such as oil and gas, chemicals and power, the safety and reliability of valves can directly affect the stability of production systems. The standards set by API (American Petroleum Institute) are the technical bible of industrial valves around the world. Among them, API 607 and API 608 are key specifications frequently cited by engineers and buyers.

This article will…

Vehicle API Market 2023 | Futuristic Technology- CarAPI, Caruso, One Auto API, A …

The Vehicle API market research report delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. The Vehicle API report also incorporates the current and future global market outlook in the emerging and developed markets. Moreover, the report also investigates regions/countries expected to witness the fastest growth rates during the forecast period.

The Vehicle API research report also provides insights of different regions that are…

Face Recognition API Market Growth, Business Overview 2023, and Forecast to 2030 …

Facial recognition is a way of recognizing a human face through technology. A facial detection system uses biometrics to map facial features from a photograph or video. It compares information with a database of known faces to find a match. Moreover, the accuracy of facial recognition systems has improved way better in the last decade. Recent market developments and competitive strategies such as expansion, product launch, and development, partnership, merger,…

API Management Market Report 2018: Segmentation by Solution (API Portal, API Gat …

Global API Management market research report provides company profile for Akana, Inc. (U.S.), Apiary, Inc. (U.S.), Axway, Inc. (France), CA Technologies, Inc. (U.S.), Cloud Elements, Inc. (U.S.), Dell Boomi, Inc. (U.S.), DigitalML (U.S.), Fiorano Software, Inc. (U.S.), Google, Inc. (U.S.), Hewlett-Packard Enterprises Co. (U.S.), IBM Corporation (U.S.), Mashape Inc. (U.S.) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical…

Telecom API Market: OTT Service Providers Continue Cutting into Telecom API Prof …

The highly fragmented market of telecom API holds a staggering number of service providers and aggregators that are already offering their APIs to various telecom carriers. Alcatel Lucent, Apigee Corp., and Fortumo OU were the leading providers of telecom API from a global perspective in 2014. Telecom carriers have partnered with them and other prominent players in the past to launch APIs in the market.

According to Transparency Market Research’s latest…