Press release

Bioreactors Market Size to Reach USD 19.6 Billion by 2033 | CAGR of 10.4%

IMARC Group's latest research report, titled "Bioreactors Market Size, Share, Trends, and Forecast by Type, Usage, Scale, Control Type, and Region, 2025-2033," offers a comprehensive analysis of the industry, which comprises insights on the bioreactors market revenue. The report also includes competitor and regional analysis, and contemporary advancements in the market. the global bioreactors market size was valued at USD 8.0 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 19.6 Billion by 2033, exhibiting a CAGR of 10.4% during 2025-2033. North America currently dominates the market, holding a significant market share of over 39.1% in 2024. The increasing adoption of effective treatment drugs, along with the rising need for preventive vaccines, is primarily propelling the bioreactors market share.Request Free Sample Report (Exclusive Offer on this report): https://www.imarcgroup.com/bioreactor-market/requestsample

Surge in Biopharmaceuticals and Personalized Medicine Driving Market Expansion:

The bioreactors market is experiencing unprecedented growth, propelled by the global surge in demand for biopharmaceuticals, including monoclonal antibodies, vaccines, biosimilars, and cell and gene therapies. This expansion is underpinned by the healthcare industry's shift toward targeted and personalized medicine, which necessitates scalable, flexible, and highly controlled bioprocessing solutions. Bioreactors are at the core of this transformation, enabling precise control over critical parameters such as temperature, pH, dissolved oxygen, agitation, and nutrient supply, which are essential for consistent cell growth and optimal product yields. The rise in chronic diseases, the need for rapid vaccine development, and the increasing adoption of preventive healthcare measures have all contributed to a robust pipeline of biologics and advanced therapies.

As a result, pharmaceutical and biotechnology companies are ramping up investments in bioreactor technologies to accelerate research, development, and commercial-scale manufacturing. The market's expansion is further supported by favorable government policies, funding for biomanufacturing infrastructure, and regulatory incentives for biosimilar production. North America and Europe remain dominant regions, benefiting from established biopharma industries and strong R&D ecosystems, while Asia-Pacific is emerging as a high-growth market due to expanding healthcare investments and a burgeoning local biotech sector.

Rapid Adoption of Single-Use and Hybrid Bioreactor Technologies:

A defining trend in the bioreactors market is the rapid adoption of single-use and hybrid bioreactor systems, which are revolutionizing bioprocessing by offering enhanced flexibility, reduced contamination risks, and lower operational costs. Single-use bioreactors, constructed from disposable polymeric materials, eliminate the need for time-consuming cleaning and sterilization processes, thereby accelerating production turnaround and supporting multiproduct manufacturing facilities. This is particularly advantageous for contract manufacturing organizations (CMOs) and biopharma companies developing diverse product pipelines or shifting between small-batch and large-scale production. Hybrid systems, which combine the robustness of stainless steel with the convenience of disposable components, are gaining traction for their ability to balance scalability, longevity, and process efficiency.

The rise of continuous bioprocessing-enabled by advances in automation, real-time monitoring, and integrated control systems-is further driving the demand for innovative bioreactor designs. These technological advancements not only streamline operations but also support regulatory compliance by minimizing cross-contamination and ensuring reproducibility. As the industry continues to prioritize cost-effectiveness, operational agility, and product quality, the shift toward single-use and hybrid bioreactors is expected to accelerate, reshaping the competitive landscape and fostering new business models in biomanufacturing.

Technological Innovation and Strategic Collaborations Fueling Growth:

Technological innovation is a cornerstone of the bioreactors market, with ongoing advancements in automation, data analytics, and process integration driving efficiency and scalability. The integration of advanced sensors, real-time analytics, and artificial intelligence into bioreactor systems allows for precise control and optimization of cell culture conditions, leading to higher yields and consistent product quality. Strategic collaborations between bioprocessing technology providers, pharmaceutical companies, and research institutions are accelerating the development and deployment of next-generation bioreactors. For instance, partnerships that integrate mass spectrometry and multi-parallel bioreactor platforms are enhancing process development by providing comprehensive data for clone selection, process optimization, and quality control. These collaborations not only foster innovation but also enable knowledge sharing, reduce time-to-market, and support regulatory compliance.

Additionally, the market is witnessing increased investment in modular and scalable bioreactor systems, which can be rapidly deployed and adapted to evolving production needs. This is particularly relevant in the context of global health emergencies, where rapid vaccine and therapeutic production is critical. As the competitive landscape intensifies, leading market players are leveraging technological advancements and strategic alliances to expand their product portfolios, enhance customer value, and capture emerging opportunities in biopharmaceutical and biotechnology manufacturing.

Leading key Players Operating in the Bioreactors Industry:

• 2mag AG

• bbi-biotech GmbH

• Bioengineering AG

• Eppendorf SE

• Getinge AB

• Infors AG

• Merck KGaA

• Pall Corporation (Danaher Corporation)

• Sartorius AG

• Solaris Biotechnology Srl

• Thermo Fisher Scientific Inc

Bioreactors Market Trends:

The bioreactors market is defined by a convergence of innovation, flexibility, and regulatory alignment, shaping its ongoing evolution. The adoption of single-use bioreactors is accelerating, driven by the need for rapid production cycles, reduced contamination risks, and the flexibility to support multiproduct manufacturing and personalized therapies. Continuous bioprocessing is gaining traction, enabled by advancements in automation and integrated control systems, which streamline operations and improve process efficiency. The market is also witnessing a shift toward modular and scalable bioreactor systems, allowing manufacturers to quickly adapt to changing production demands and scale operations in response to new therapeutic developments. Strategic collaborations between technology providers and biopharmaceutical companies are fostering the integration of advanced analytics, real-time monitoring, and artificial intelligence, further enhancing process control and product quality.

Regulatory support for biosimilars and personalized medicine is encouraging investment in innovative bioreactor technologies that meet stringent quality and safety standards. As the biotechnology and pharmaceutical industries continue to expand, the demand for robust, flexible, and efficient bioreactor solutions will remain a central driver of market growth, positioning bioreactors as a critical enabler of the next generation of biomanufacturing.

Ask Analyst for Instant Discount and Download Full Report with TOC & List of Figure: https://www.imarcgroup.com/bioreactor-market

Key Market Segmentation:

Breakup by Product Type:

• Glass

• Stainless Steel

• Single-Use

Among these, single-use currently exhibit a clear dominance in the market.

Breakup by Usage:

• Lab-Scale Production

• Pilot-Scale Production

• Full-Scale Production

Currently, pilot-scale production holds the largest bioreactor market share.

Breakup by Scale:

• 5L-20L

• 20L-200L

• 200L-1500L

• Above 1500L

Breakup by Control Type:

• Manual

• Automated

Currently, automated holds the largest bioreactor market share.

Breakup by Region:

• North America (United States, Canada)

• Asia Pacific (China, Japan, India, Australia, Indonesia, Korea, Others)

• Europe (Germany, France, United Kingdom, Italy, Spain, Others)

• Latin America (Brazil, Mexico, Others)

• Middle East and Africa (United Arab Emirates, Saudi Arabia, Qatar, Iraq, Other)

North America currently dominates the market.

Key Highlights of the Report:

• Market Performance (2019-2024)

• Market Outlook (2025-2033)

• Porter's Five Forces Analysis

• Market Drivers and Success Factors

• SWOT Analysis

• Value Chain

• Comprehensive Mapping of the Competitive Landscape

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Bioreactors Market Size to Reach USD 19.6 Billion by 2033 | CAGR of 10.4% here

News-ID: 4094167 • Views: …

More Releases from IMARC Group

Biofertilizer Production Plant DPR & Unit Setup - 2026: Investment Cost, Market …

The global biofertilizer production industry is witnessing robust growth driven by the rapidly expanding organic farming, sustainable agriculture, and soil health management sectors and increasing demand for eco-friendly agricultural inputs that reduce chemical fertilizer dependence. At the heart of this expansion lies a critical agricultural innovation-biofertilizers. As farmers and agricultural stakeholders worldwide transition toward environmentally responsible farming practices and government policies promote sustainable agriculture, establishing a biofertilizer production plant presents…

PVC Pipes Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpE …

The global PVC pipes manufacturing industry is witnessing robust growth driven by the rapidly expanding construction, water infrastructure, agricultural irrigation, and industrial sectors and increasing demand for durable, cost-effective, and corrosion-resistant piping solutions. At the heart of this expansion lies a critical infrastructure material-PVC pipes. As governments worldwide invest heavily in water supply systems, sanitation infrastructure, and smart city development, establishing a PVC pipes manufacturing plant presents a strategically compelling…

Sorbitol Production Plant DPR 2026: CapEx/OpEx Analysis with Profitability Forec …

The global sorbitol production industry is witnessing steady growth driven by the rapidly expanding food and beverage, pharmaceutical, and personal care sectors and increasing demand for sugar substitutes, humectants, and functional ingredients. At the heart of this expansion lies a critical polyol product-sorbitol. As consumers worldwide transition toward low-calorie, sugar-free, and health-conscious product choices, establishing a sorbitol production plant presents a strategically compelling business opportunity for entrepreneurs and specialty ingredients…

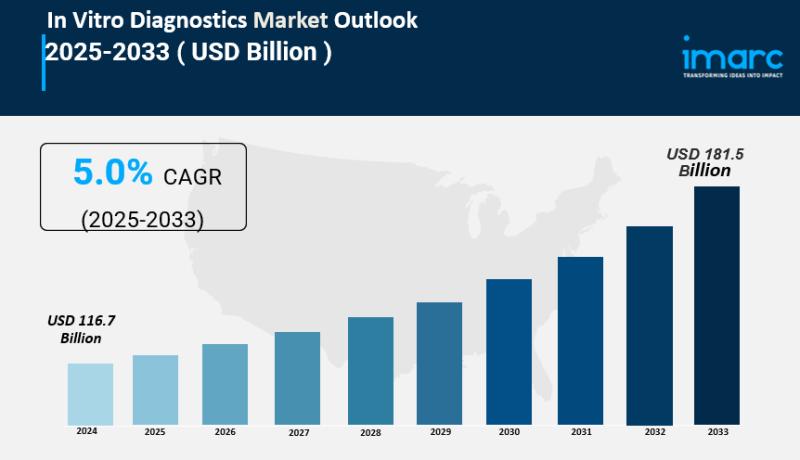

In Vitro Diagnostics Market is Expected to Grow USD 181.5 Billion by 2033 | At C …

IMARC Group, a leading market research company, has recently released a report titled "In Vitro Diagnostics Market Size, Share, Trends and Forecast by Product, Material, Distribution Channel, Pricing, End-User, and Region, 2025-2033." The study provides a detailed analysis of the industry, including the In Vitro Diagnostics market size, share, trends, and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

In Vitro…

More Releases for Bioreactor

Water Pollution Surge Spurs Growth In The Membrane Bioreactor Market: An Emergin …

The Membrane Bioreactor Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Projected Growth of the Membrane Bioreactor Market?

The market size for membrane bioreactors has experienced swift expansion in the last few years. The forecast predicts an escalation from $4.24 billion in 2024…

Technological Innovations Propel The Membrane Bioreactor Market Forward Trend: A …

What industry-specific factors are fueling the growth of the membrane bioreactor market?

The escalation in water contamination levels is playing a substantial role in propelling the membrane bioreactor market's expansion. The phenomenon of water pollution is characterized by the release of harmful chemicals or organisms into bodies of water such as rivers, lakes, and seas. Such instances of water pollution sprout from the lack of clean, potable water. Amidst the surge…

Cellbag Bioreactor Chambers Market - Seamless Cell Culturing: Cellbag Bioreactor …

Newark, New Castle, USA: The "Cellbag Bioreactor Chambers Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors.

Cellbag Bioreactor Chambers Market: https://www.growthplusreports.com/report/cellbag-bioreactor-chambers-market/8938

This latest report researches the industry structure,…

Microbial Bioreactor Market

The Global Microbial Bioreactor Market is expected to grow at a CAGR of 20.1% during the forecasting period (2022-2029).

Micro bioreactors serve as a multitude of scale-down needs for bioprocesses based on mammalian cells. Microbioreactor technology has allowed for rapid advancements in biotechnology process development and investigation of various biological systems from industrial biotechnology and pharmaceutical biotechnology. Micro bioreactors range in complexity from simple micro-tier-based systems to complex automated parallel bioreactors…

Global Membrane Bioreactor Market - Forecasts to 2026

The findings reviewed by GME stated that the Global Membrane Bioreactor Market will expand with a CAGR value of 7.0 percent from 2021 to 2026. The Membrane Bioreactor (MBR) market will expand rapidly due to increased ecological concerns about wastewater management and dwindling freshwater resources., population growth, shifting consumer habits, global warming, urbanization, and industrialization.

Browse 159 Market Data Tables and 119 Figures spread through 189 Pages and in-depth TOC on…

Single Use Bioreactor Market Assessment 2017-2021

Single use bioreactors are witnessing rapid market growth due to increasing applications in production of antibodies, vaccines, recombinant proteins, growth factors and others. Single use bioreactors are not only used in pharmaceutical companies, but also in biotechnology research laboratories and contract manufacturing organizations. Single use bioreactors assure sterile conditions to quickly initiate production. This greatly reduced chances of cross contamination and increases productivity. Shorter turnaround time due to ease of…