Press release

AI-Optimized Smart Factories Market: Trends, Growth, and Future Outlook (2025 - 2035)

The global AI-optimized smart factories market size was valued at US$ 6.5 Bn in 2024. AI-optimized smart factories industry forecasts suggest that the market is expected to grow at an exponential CAGR during the forecast period 2025-2035. The AI-powered smart manufacturing market is characterized by many prominent trends such as the acceptance of AI-based automation, predictive maintenance, and real-time analytics.AI-optimized smart factories represent the convergence of advanced robotics, machine learning, and data analytics within manufacturing environments. These factories leverage AI to enhance automation, improve decision-making, and increase adaptability to changing market demands. The adoption of AI in manufacturing is driven by the need for increased productivity, reduced operational costs, and the ability to produce complex products with higher precision.

Unlock Full Market Insights: Get a Sample Report Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86553

Automotive, electronics, and pharmaceuticals are some of the major sectors heavily investing in smart manufacturing for raising their production level and flexibility. Increasing needs have demanded predictive maintenance, real-time monitoring, and energy efficiency, which drive market growth.

Market Segmentation

The market can be segmented based on:

Service Type: Consulting, implementation, maintenance, and support services.

Sourcing Type: In-house development, third-party providers, and hybrid models.

Application: Assembly, welding, painting, material handling, and quality inspection.

Industry Vertical: Automotive, electronics, pharmaceuticals, food and beverage, and consumer goods.

Region: North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa.

Regional Analysis

The Asia-Pacific region, particularly China, is at the forefront of adopting AI-optimized smart factories. Companies like Xiaomi have unveiled fully automated, AI-driven facilities capable of operating 24/7 without human intervention, producing one smartphone per second. Despite leading in industrial robot installations, China's robotics sector remains reliant on foreign components and faces challenges due to potential sanctions and technological dependencies.

Market Drivers and Challenges

Drivers:

Labor Shortages: An aging workforce and declining interest in manufacturing jobs have led to labor shortages, prompting the adoption of automation.

Technological Advancements: Innovations in AI, robotics, and IoT have made smart factories more feasible and cost-effective.

Demand for Customization: Consumers' increasing demand for personalized products requires flexible and adaptive manufacturing processes.

Challenges:

High Implementation Costs: The initial investment for setting up AI-optimized facilities can be substantial.

Skill Gaps: There is a shortage of skilled professionals capable of managing and maintaining advanced AI systems.

Data Security: Integrating AI increases the risk of cyber threats and data breaches.

Market Trends

Rise of 'Dark Factories': Fully automated factories operating without human intervention are becoming more prevalent, enhancing efficiency and reducing errors.

AI as a Core Business Component: Companies are evolving into 'AI factories,' focusing on generating data (tokens) to improve AI models and business operations.

Integration of Humanoid Robots: The development and deployment of humanoid robots capable of performing complex tasks alongside human workers are on the rise.

Future Outlook

The AI-optimized smart factories market is poised for significant expansion over the next decade. As AI technologies become more sophisticated and accessible, their integration into manufacturing will deepen, leading to smarter, more efficient, and highly adaptable production environments. This transformation is expected to create new business models, enhance competitiveness, and drive economic growth across various sectors.

Key Market Study Points

Assessing the impact of AI integration on production efficiency and product quality.

Evaluating the return on investment for AI-optimized manufacturing solutions.

Understanding the evolving regulatory landscape surrounding AI in manufacturing.

Identifying emerging opportunities and threats within the market.

Competitive Landscape

The market features a mix of established technology giants and innovative start-ups. Companies like Nvidia are transitioning from chip-making to becoming central players in the industrial economy, developing high-end robotics and software that drive manufacturing automation. Collaborations between tech companies and traditional manufacturers are becoming common, aiming to leverage AI for enhanced production capabilities.

Explore Our Report for Comprehensive Insights! https://www.transparencymarketresearch.com/ai-optimized-smart-factories-market.html

Recent Developments

Nvidia's AI Initiatives: Nvidia CEO Jensen Huang announced the next generation of AI and computing chips, predicting a "multitrillion-dollar opportunity" for AI in various industries, including manufacturing.

Xiaomi's Dark Factory: Xiaomi unveiled a fully automated, AI-driven manufacturing facility capable of producing one smartphone per second without human intervention.

AI-optimized smart factories market is on a trajectory of rapid growth and transformation. While challenges such as high implementation costs and skill gaps remain, the potential benefits of increased efficiency, reduced operational costs, and enhanced product quality position AI as a cornerstone of future manufacturing paradigms.

Explore Latest Research Reports by Transparency Market Research:

Vibrating Conveyor Market - https://www.transparencymarketresearch.com/vibrating-conveyors-market.html

Truck-mounted Cranes Market - https://www.transparencymarketresearch.com/truck-mounted-cranes-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AI-Optimized Smart Factories Market: Trends, Growth, and Future Outlook (2025 - 2035) here

News-ID: 3949880 • Views: …

More Releases from transparencymarketresearch

Microgreens Market to Surge at 10.9% CAGR, Set to Reach USD 8.56 Billion by 2036

The global microgreens market was valued at USD 2,780.5 million in 2025 and is projected to reach USD 8,563.5 million by 2036. Driven by rising demand for nutrient-dense foods and growing adoption across foodservice and retail channels, the industry is expected to expand at a robust CAGR of 10.9% from 2026 to 2036.

The global microgreens market represents a specialized, high-value segment within the broader fresh produce and specialty horticulture industry,…

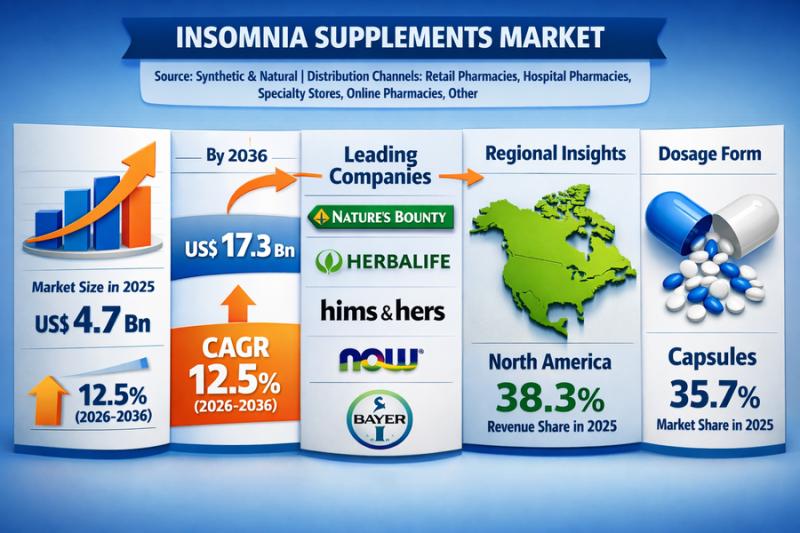

Insomnia Supplements Market Set to Reach US$ 17.3 Bn by 2036, Growing at a Robus …

The global insomnia supplements market was valued at USD 4.7 billion in 2025 and is projected to reach USD 17.3 billion by 2036, reflecting strong growth potential. The market is anticipated to expand at a CAGR of 12.5% from 2026 to 2036, driven by rising sleep disorder prevalence, increasing consumer focus on mental wellness, and growing demand for natural and non-prescription sleep aids.

The insomnia supplements market is expected to witness…

Fiber-Based Blister Pack Market Set to Surge at 21.5% CAGR Through 2036

The global fiber-based blister pack market was valued at US$ 1,633.8 million in 2025 and is projected to surge to US$ 13,591.8 million by 2036. Driven by rising demand for sustainable and eco-friendly packaging solutions, the market is expected to grow at a robust CAGR of 21.5% from 2026 to 2036.

Fiber-based blister packaging is a type of packaging that substitutes the usual plastic blister with paperboard or molded fiber components…

Psychotropic Drugs Market to Reach US$ 41.2 Bn by 2036, Growing at 5.4% CAGR

The global psychotropic drugs market was valued at USD 23.1 Bn in 2025 and is projected to reach USD 41.2 Bn by 2036. Driven by rising awareness of mental health disorders, increasing diagnosis rates, and ongoing pharmaceutical innovations, the industry is expected to grow at a CAGR of 5.4% from 2026 to 2036.

The primary drivers of the expanding psychotropic drugs market include the rising prevalence of mental disorders such as…

More Releases for Factories

Expanding The Hotel Furniture Portfolio with Chinese Factories

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/316a0a97d95a40e999be35e34803497e.webp

Unlock significant advantages for your hotel furniture portfolio. Sourcing from Chinese factories presents unique opportunities for growth. This guide outlines how to navigate this process successfully. It ensures you achieve superior quality and value. Mastering these steps is crucial for optimal outcomes.

Key Takeaways

* Sourcing hotel furniture from China [https://www.taisenfurniture.com/news/5-key-factors-when-sourcing-hotel-casegoods-from-china/] offers lower costs and many design choices.

* Define your needs, find good factories, and check samples before making big orders.

*…

Introduction: From Traditional Stone Grinding to Intelligent Factories

In the long river of human civilization, food processing has always been the core link of agricultural industrialization. From primitive stone mills to modern intelligent production lines, the powder milling process has undergone earth shaking changes. Nowadays, with the deep integration of artificial intelligence, precision machinery, and optical technology, core technologies such as color selection, grinding, and screening have become the soul of modern milling processes. They not only ensure…

Global Economic Shifts Affecting Ceramic Tableware Factories

In recent years, the ceramic tableware industry has been navigating a complex landscape shaped by global economic shifts, fluctuating raw material prices, and geopolitical tensions. These factors are impacting production costs, supply chain reliability, and market demand, forcing manufacturers to adapt quickly in order to stay competitive.

Volatile Raw Material Prices

One of the key challenges for ceramic tableware manufacturers is the volatility in raw material costs. The prices of key materials…

Plant factories are in demand

From the perspective of agricultural development, modern agriculture has been able to rapidly increase yields to meet the huge demand for food generated by the burgeoning population due to the use of chemical fertilizers and pesticides and has been instrumental in solving the global food and poverty problems. However, traditional agriculture is purely dependent on the weather and seasons, not only can crop cultivation be restricted by climate and seasons,…

Monitoring Industrial Manufacturing Processes in Factories & Plants

Delphin Systems Offer Standalone Operation and Automation

Above all, industrial manufacturing processes in factories and plants must function smoothly. Downtimes for these continuous processes have to be minimized to avoid the resulting costs involved. Consequently, process monitoring is essential for error-free products and for maintaining the required quality standards.

Delphin ProfiMessage and Expert devices are single solutions for automating monitoring tasks of industrial manufacturing processes. Delphin systems are ideal due to their…

Plan systems and factories even better with MPDS4 6.2

Version 6.2 offers lots of new productivity improvements and functions to the plant construction and factory planning software MPDS4.

Cambridge, UK and Pittsford, NY - 21 June 2017: MPDS4 version 6.2 includes a large amount of new functions for improved reporting and simpler handling. The expansion and optimisation of interfaces simplifies the exchange of data with customers and suppliers.

Simpler and better planning

The main focus of version 6.2 was to achieve easier…