Press release

Welded Metal Bellows Market Expected to Grow at a CAGR of 5.9% by 2031 | Persistence Market Research Analysis

IntroductionThe demand for high-performance components in industries such as aerospace, automotive, medical, and semiconductor manufacturing has driven significant growth in the welded metal bellows market. These precision-engineered components offer superior flexibility, durability, and leak-tight performance, making them essential for applications requiring motion compensation, pressure regulation, and environmental isolation.

Welded metal bellows are highly versatile and are widely used in demanding environments where reliability and precision are crucial. Their ability to withstand extreme temperatures, high pressure, and corrosive conditions has made them a preferred choice for various high-tech applications. According to Persistence Market Research, the global welded metal bellows market is projected to reach USD 461.1 million by 2031, expanding at a CAGR of 5.9%. This growth is driven by increasing adoption across multiple industries, advancements in manufacturing technologies, and the rising need for precision-engineered solutions.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/34882

Market Overview and Growth Drivers

The welded metal bellows market has been witnessing steady growth due to various factors. One of the primary drivers is the increasing use of these components in aerospace and defense applications. The aerospace industry, in particular, relies on welded metal bellows for critical functions such as fuel system control, actuator systems, and thermal management. The demand for high-performance materials capable of withstanding extreme operating conditions has pushed manufacturers to innovate and enhance the capabilities of these bellows.

In the automotive sector, the growing emphasis on fuel efficiency, emission reduction, and advanced engine control systems has led to an increased demand for welded metal bellows. These components play a crucial role in exhaust gas recirculation (EGR) systems, turbochargers, and vibration isolation mechanisms, contributing to improved vehicle performance and environmental compliance.

The semiconductor industry is another major growth driver for the market. With the expansion of semiconductor manufacturing facilities worldwide, the demand for ultra-clean and precise motion control solutions has surged. Welded metal bellows are extensively used in vacuum and gas control systems within semiconductor fabrication processes, ensuring contamination-free operation and high precision.

Additionally, the medical industry has emerged as a key consumer of welded metal bellows. The increasing adoption of advanced medical devices, such as robotic surgical instruments, ventilators, and implantable drug delivery systems, has fueled demand for precision components that offer flexibility and reliability. Welded metal bellows enable smooth operation and enhance the performance of life-saving medical equipment.

Technological Advancements Shaping the Market

Innovations in material science and manufacturing processes have played a pivotal role in expanding the application scope of welded metal bellows. The use of advanced alloys, such as Inconel, titanium, and stainless steel, has improved the durability and performance of these components in extreme conditions. These materials offer enhanced resistance to corrosion, fatigue, and temperature variations, making them ideal for aerospace, energy, and chemical processing applications.

Laser welding technology has significantly improved the precision and consistency of welded metal bellows. High-precision laser welding ensures minimal heat distortion, superior weld strength, and enhanced leak-tight properties, which are critical for high-performance applications. This technology has enabled manufacturers to produce highly customized bellows tailored to specific industry needs.

Miniaturization is another notable trend in the welded metal bellows market. With the increasing demand for compact and lightweight components in aerospace, medical, and semiconductor industries, manufacturers are focusing on developing micro-sized bellows with exceptional flexibility and performance. These miniature bellows are crucial for applications such as micro-electromechanical systems (MEMS), precision sensors, and miniature actuators.

The integration of smart materials and sensors into welded metal bellows is a recent development that holds great potential. Smart bellows equipped with embedded sensors can monitor performance parameters such as pressure, temperature, and stress levels in real time, enabling predictive maintenance and enhancing system efficiency. This advancement is particularly valuable in aerospace, industrial automation, and energy applications, where operational reliability is critical.

Market Segmentation and Key Applications

Welded metal bellows find applications across diverse industries, each with unique requirements and specifications. The market can be categorized based on material type, end-use industry, and application.

In terms of material type, stainless steel bellows are the most widely used due to their excellent corrosion resistance, strength, and cost-effectiveness. Inconel and titanium bellows are preferred for high-performance applications where extreme conditions and high temperatures are prevalent, such as aerospace and nuclear energy sectors.

The aerospace and defense sector dominates the welded metal bellows market, accounting for a significant share of demand. These components are used in fuel control systems, hydraulic systems, and aircraft instrumentation, ensuring precision and reliability in critical flight operations. The stringent safety and performance standards in this industry drive continuous advancements in bellow design and manufacturing.

In the automotive industry, welded metal bellows are integral to engine management systems, exhaust control, and fluid transfer mechanisms. The shift towards electric and hybrid vehicles has also created new opportunities for bellows in battery cooling systems and thermal management applications.

The semiconductor manufacturing industry requires ultra-clean and high-precision components for vacuum systems, wafer handling, and gas flow regulation. Welded metal bellows play a crucial role in maintaining contamination-free environments within semiconductor fabrication facilities, supporting the growth of advanced chip manufacturing technologies.

Medical applications of welded metal bellows continue to expand, driven by the increasing demand for minimally invasive surgical instruments, precision drug delivery systems, and high-performance medical sensors. These components enhance the functionality and reliability of critical medical devices, ensuring patient safety and improved treatment outcomes.

Competitive Landscape and Key Players

The welded metal bellows market is highly competitive, with several key players driving innovation and technological advancements. Leading manufacturers are focusing on product development, strategic collaborations, and expansion into emerging markets to strengthen their market position.

Some of the prominent players in the market include:

MW Industries - A global leader in precision-engineered metal components, offering a wide range of welded metal bellows for aerospace, medical, and industrial applications.

Technetics Group - Specializes in high-performance sealing and bellow solutions for demanding industries such as energy, aerospace, and semiconductor manufacturing.

Senior plc - A major supplier of engineered components, including welded metal bellows, catering to the aerospace, defense, and automotive sectors.

Metal Flex Welded Bellows - Known for customized bellow solutions tailored to specific industry requirements.

BellowsTech - Focuses on high-precision welded bellows for medical, semiconductor, and aerospace applications.

These companies are investing in advanced manufacturing techniques, automation, and research & development to enhance product quality and meet the evolving needs of end-users.

Challenges and Market Constraints

Despite the positive growth trajectory, the welded metal bellows market faces several challenges. One of the primary concerns is the high cost of raw materials, particularly specialty alloys like Inconel and titanium. Fluctuations in metal prices can impact production costs and profitability for manufacturers.

Manufacturing complexities and stringent quality control requirements also pose challenges. The precision welding process for metal bellows demands specialized equipment and skilled labor, making production cost-intensive. Ensuring consistent quality and performance across different applications requires rigorous testing and certification procedures.

Supply chain disruptions, particularly in the wake of global crises such as the COVID-19 pandemic, have affected the availability of raw materials and components. Manufacturers are adopting strategic sourcing and localizing supply chains to mitigate these risks and ensure uninterrupted production.

Future Outlook and Emerging Trends

The future of the welded metal bellows market is promising, with continuous advancements in material science, manufacturing processes, and application areas. The growing demand for high-precision components in next-generation technologies, including electric vehicles, space exploration, and renewable energy, will drive market expansion.

The rise of Industry 4.0 and smart manufacturing practices is expected to enhance production efficiency and quality control. Automated welding and robotic assembly processes will further improve the consistency and scalability of bellow manufacturing.

Sustainability and environmental considerations are also gaining traction in the market. The adoption of eco-friendly materials, energy-efficient production techniques, and recyclable components will become key focus areas for manufacturers striving to align with global sustainability goals.

Conclusion

The welded metal bellows market is on a steady growth trajectory, fueled by increasing industrial applications, technological advancements, and the demand for precision-engineered components. With an expected market value of USD 461.1 million by 2031 and a CAGR of 5.9%, the industry is poised for significant expansion.

As industries continue to evolve and demand higher-performance solutions, welded metal bellows will play a crucial role in enabling innovation across aerospace, automotive, semiconductor, and medical sectors. Manufacturers that invest in research, automation, and sustainability will be well-positioned to capitalize on the growing opportunities in this dynamic market.

Explore the Latest Trending "Exclusive Article":

· https://medtechpulse.wordpress.com/2025/02/10/surface-disinfectant-market-key-players-and-competitive-landscape-analysis/

· https://medtechpulse.wordpress.com/2025/02/10/ultra-low-temperature-freezer-market-adoption-in-pharma-and-biotech-sectors/

· https://medtechpulse.wordpress.com/2025/02/11/antibody-library-technology-market-driving-precision-medicine-forward/

· https://medium.com/@aishwaryadoiphode15/cell-free-protein-expression-market-advances-in-synthetic-biology-solutions-1206e613b7af

· https://medium.com/@aishwaryadoiphode15/europe-medical-plastic-market-key-trends-shaping-the-industrys-future-growth-881197ff0b2b

· https://www.manchesterprofessionals.co.uk/article/business-management/82523/orthopedic-trauma-devices-market-future-projections-and-investment-insights

· https://www.manchesterprofessionals.co.uk/article/business-management/82534/europe-medical-plastic-market-role-of-recyclable-polymers-in-sustainable-growth

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Welded Metal Bellows Market Expected to Grow at a CAGR of 5.9% by 2031 | Persistence Market Research Analysis here

News-ID: 3882372 • Views: …

More Releases from Persistence Market Research

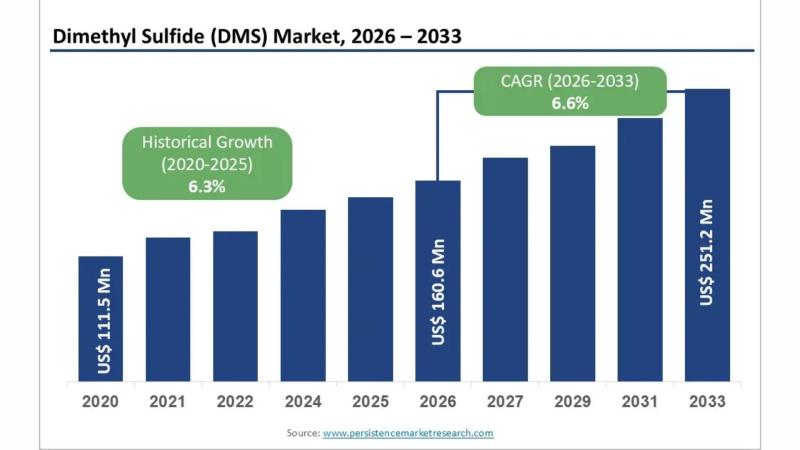

Dimethyl Sulfide (DMS) Market Anticipated to Reach US$ 251.2 Mn by 2033, Driven …

Market Overview: Expanding Demand for Dimethyl Sulfide Across Industries

The Dimethyl Sulfide (DMS) market is witnessing consistent growth due to its widespread applications across food processing, pharmaceuticals, agriculture, and chemical manufacturing. Dimethyl sulfide is an organosulfur compound known for its distinctive odor and reactive properties, making it a crucial intermediate in multiple industrial processes. In food and beverage applications, it is valued for flavor enhancement, while in chemical manufacturing, it serves…

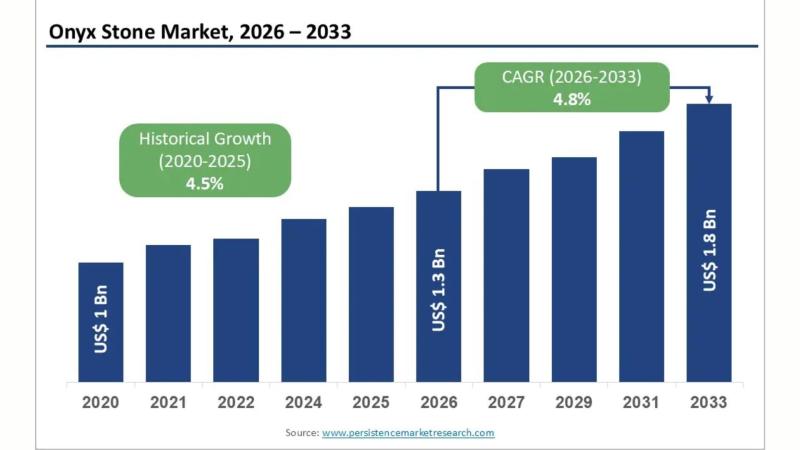

Onyx Stone Market to Surge to Reach US$ 1.8 Bn by 2033 Driven by Construction & …

Market Overview: Rising Demand for Premium Natural Stones

The onyx stone market has gained remarkable prominence in recent years, driven by increasing demand for luxury natural stones in architecture, interior décor, and artistic applications. Onyx, known for its translucent appearance and unique veining patterns, has become a preferred choice for premium residential and commercial projects. The material's ability to elevate aesthetic appeal while maintaining durability has attracted designers, architects, and homeowners…

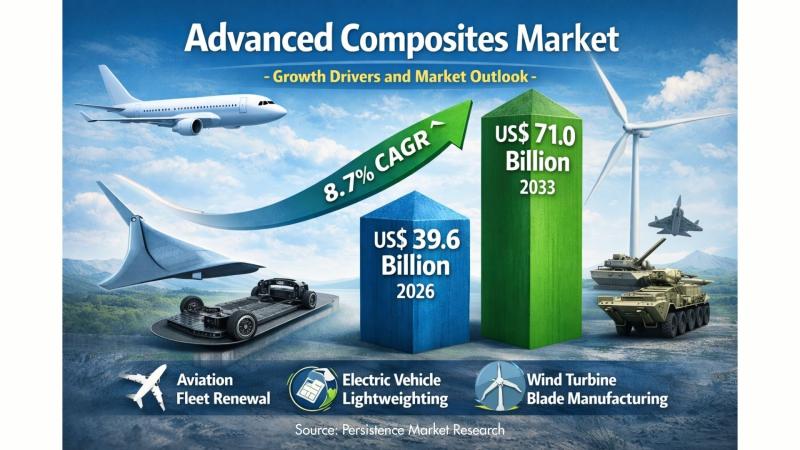

Advanced Composites Market to Attain US$71.0 Bn Growth by 2033 Driven by Lightwe …

Introduction: The Rising Importance of Advanced Composites

The global industrial landscape is witnessing a major material transformation as manufacturers increasingly prioritize lightweight, high-strength, and durable solutions. Advanced composites have emerged as a vital material category that meets these requirements while supporting sustainability, energy efficiency, and performance optimization. These composites, engineered using high-performance fibers and resins, offer superior mechanical strength, corrosion resistance, and design flexibility compared to conventional materials such as steel…

Cable Cars and Ropeways Market Set to Reach US$ 9.7 Bn by 2032, Growing at 11.4% …

The Cable Cars and Ropeways Market has emerged as a critical component of modern transportation infrastructure, particularly in regions with challenging terrain, dense urban centers, and growing tourism activities. Cable cars and ropeways are transport systems equipped with installed cables, supported by one or two stationary ropes and powered by an operational rope for propulsion. Often referred to as elevated streetcars, these systems offer an efficient, sustainable, and space-saving alternative…

More Releases for Welded

Welded Parts Applications & Manufacturing

Welded parts [https://www.simis-manufacturer.com/products/], with their reliable connection performance and structural strength, are widely used in various industries.

In the mechanical manufacturing industry, it is often used in the manufacturing of core components such as machine tool beds, construction machinery frames, and pressure vessels. Through welding, multiple metal components are connected into a whole to meet the equipment's requirements for structural stability and load-bearing capacity. For example, the boom of an excavator…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing notable growth due to increased demand for high-performance components in industries requiring…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is witnessing steady growth due to the rising demand for precision-engineered components in high-performance…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing steady growth due to increasing demand across high-precision industries such as aerospace,…

Carbon welded steel pipe factory

LSAW Carbon Steel Pipe

Pipe Type:LSAW Steel Pipe,Longitudinally Submerged Arc Welding Pipe ,DSAW Steel Pipe,Welded Steel Pipe

Specification: Outside Diameter:355.6mm-2320mm

Wall Thickness:5.0mm-60mm

…

seamless and welded pipe

Seamless steel pipe is a round, square and rectangular steel with a hollow section and no joints on the periphery. Seamless steel pipes are made of steel ingots or solid tube billets through perforation into capillary tubes, and then made by hot rolling, cold rolling or cold drawing.

Welded steel pipes refer to steel pipes with seams on the surface that are welded after bending and deforming steel strips or steel…