Press release

All capillary thermostat and limiters in stainless steel enclosures available

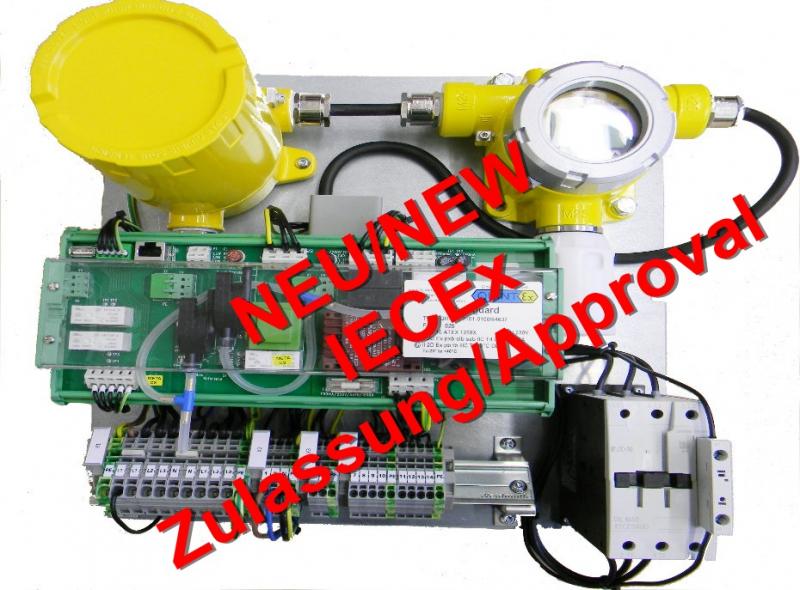

The long in use proven capillary thermostat and limiters with a 16 A switching capacity are now not only available in glass fiber reinforced polyester enclosures but also in stainless steel enclosures. This is also done for the combination of controller and limiter.All enclosures are approved to IECEx and ATEX, as well as meet standard requirements of NEMA 4X.

You can use this controller and limiter also directly as a junction box of the heating system. This ease installation and maintenance of trace heating with constant wattage systems.

On our website all the important data can be viewed and both sheet and operating instructions are ready for download.

The IRB2M..VAEx series of fail-safe temperature devices consist of capillary type thermostats with mechanical change-over contacts in stainless steel enclosures. These are commonly used in applications for controlling and connecting single-core heating cables in hazardous areas. The combination of limiter & thermostat allows simple and space-saving connections for electrical trace heating circuits. These stainless steel enclosures are approved to ATEX/IECEx and NEMA 4X and have proven themselves extremely well under harsh environmental conditions and for food & hygiene areas. These rugged & robust enclosures stand up well to aggressive chemicals and severe mechanical impacts.

http://www.quintex.eu/en/IRBM2_en.html

Specifically, the combination of controller and limiter offers the possibility in the hazardous area to build up a trace heating system for 'controlled design' according to 60079-30.

With 4mm capillaries the capillary tube reacts fast to temperature changes. All limiters are 'fail-safe' constructed i.e. in case of failure, the trace heating is switched off.

With our approval for the controlled design everyone can build up trace heating systems with constant wattage heating tapes, heating cable in polymer sheathing or mineral insulated type. There is no need for further on site approval.

Please contact us if you have questions about the equipment or the construction of a heat-tracing as controlled design.

We will help you quickly and competently.

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations - all can be specified and ordered online)

We manufacture all our material in our own approved (ATEX, ISO, FM, CSA...) facility.

By this we can guarantee our high level of quality, reliability and in time delivery.

Quintex GmbH

i_Park Tauberfranken 13

97922 Lauda-Koenigshofen

Germany

+49 9343 6130 0

www.quintex.eu/en

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release All capillary thermostat and limiters in stainless steel enclosures available here

News-ID: 360267 • Views: …

More Releases from Quintex GmbH

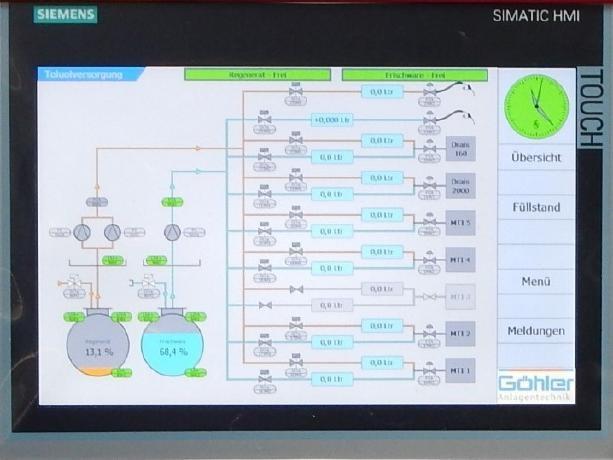

Pressurized HMI in Ex Zone 1 at an automotive supplier

Quintex GmbH was able to win an order with a leading manufacturer and OEM for sealing systems in the automobile industry together with its customer, Göhler Anlagentechnik.

For toluol supply facilities in zone 1, the customer required a system with a zone 2 panel by Siemens. In addition, the costumer required that the touch function of the twelve inch widescreen TFT display be completely retained even under harsh industrial conditions.

Different solutions…

Overpressure system with gas detection for hazardous areas (ATEX/IECEx)

We made a little video to show the ease of use of overpressure system in hazardous areas for un-approved devices. It is the easiest way to bring YOUR device into hazardous area too.

The explosion protection at the "overpressure system 2.0" is realized by operating a non-explosion-protected equipment in a protected enclosure. This housing is protected by a durable pressure with air or an inert gas prior to penetrate the enclosure…

Local Control Functions at a Fuel Loading Area

Ex certified Local control functions you find in many chemical and petrochemical Applications. A typical Application is a switch for Illumination. A big handle is therefore required to make sure that the people can switch on and off the Equipment easily also with gloves.

The requirement is often very different. The showed application is a 2-pole main switch for illumination at a Tank Truck Fuel Loading Area operated by “NIS”…

Electrical equipment in waste water treatment plants

The screen represents the first cleaning stage in a waste water treatment plant after the inlet.

With this mechanical pre-treatment, the waste water is passed through a screen or sieve. Coarse dirt of all kinds, such as stones, branches, leaves, damp toilet paper, sanitary towels and a lot of other debris, get caught there and are removed from the further clarification cycle.

Basically, different types of screens are used. These range from…

More Releases for Capillary

Emerging Capillary Electrophoresis Market Trends: Advancements In Capillary Elec …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Capillary Electrophoresis Market Size Growth Forecast: What to Expect by 2025?

The market size for capillary electrophoresis has seen robust growth in the past few years. The market is set to increase from $0.55 billion in 2024 to $0.58 billion in 2025, with a compound annual growth rate (CAGR)…

Global Bulb And Capillary Thermostat Market Size by Application, Type, and Geogr …

USA, New Jersey- According to Market Research Intellect, the global Bulb And Capillary Thermostat market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The bulb and capillary thermostat market is experiencing steady growth due to increasing demand across industrial, commercial, and residential applications. These thermostats are…

Capillary Electrophoresis Systems Market Research Report 2023 - 2029

Capillary Electrophoresis Systems Market

The global Capillary Electrophoresis Systems market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Netherlands-Ukraine War were considered while estimating market sizes.

Get Free Sample: https://reports.valuates.com/request/sample/QYRE-Auto-14R3326/Global_Capillary_Electrophoresis_Systems_Market_Insights_and_Forecast_to_2028

North American market for Capillary Electrophoresis Systems is estimated to increase from $ million in 2023 to reach $…

Capillary Blood Collection Devices Market-Forecasts to 2026

According to a new market research report published by Global Market Estimates, the Global Capillary Blood Collection Devices Market is projected to grow from USD 1.2 billion in 2021 to USD 1.5 billion by 2026 at a CAGR value of 3.7% from 2021 to 2026. The market for capillary blood collection devices expanded significantly during the covid-19 pandemic. Serological testing has proven to be a useful method for learning more…

Capillary Electrophoresis Market Size and Forecast 2025

The report comes out as an intelligent and thorough assessment tool as well as a great resource that will help you to secure a position of strength in the global Capillary Electrophoresis market. It includes Porter’s Five Forces and PESTLE analysis to equip your business with critical information and comparative data about the Global Capillary Electrophoresis Market. We have provided deep analysis of the vendor landscape to give you a…

Asia-Pacific Capillary Electrophoresis Equipment Market Report 2017

Qyresearchreports include new market research report "Asia-Pacific Capillary Electrophoresis Equipment Market Report 2017" to its huge collection of research reports.

In this report, the Asia-Pacific Capillary Electrophoresis Equipment market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Geographically, this report split Asia-Pacific into several key Regions, with sales (K…