Press release

Application story: UltraFlex's Time-Efficient Induction Brazing for Stainless Steel Tubes

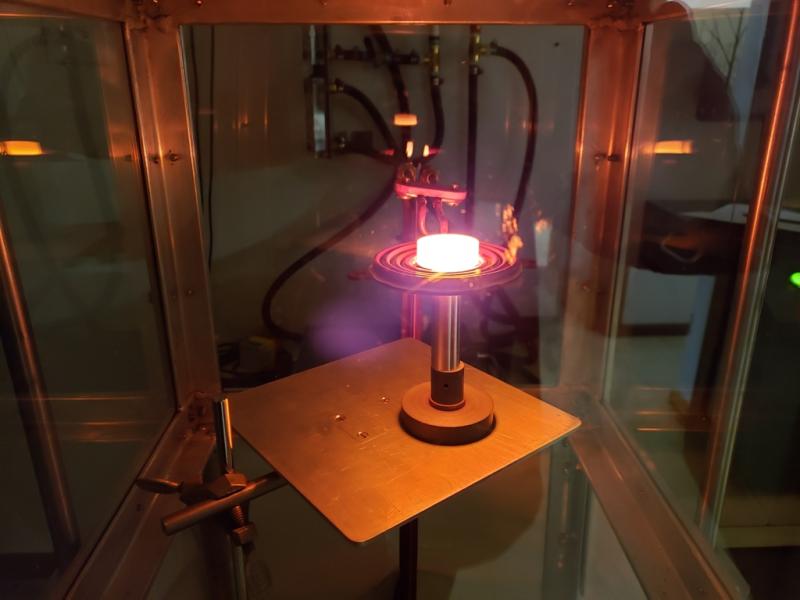

The time-efficient induction brazing process for a stainless steel assembly made of low-carbon tubing and fittings has been demonstrated by UltraFlex Power Technologies. UltraFlex is a leading manufacturer of digitally controlled, advanced induction heaters and is frequently setting up demo applications for potential customers looking to evaluate the usage of induction heating for their manufacturing processes.In this customer scenario, a manufacturer from the automotive industry was looking to replace their existing induction heating equipment with UltraFlex one and needed to evaluate the heating parameters for a major induction brazing process. The parts to be brazed in the process were a tube with 0.78" (1.98 cm) outside diameter and 0.07" (0.18 cm) wall and fitting with 0.78" (1.98 cm) internal diameter.

UltraFlex engineers recommended the usage of an induction heater from the UltraFlex SOLO series as most appropriate for this customer heating scenario. The UltraFlex SOLO Systems are a breakthrough innovation in induction heating technology, featuring a unique Direct Digital Step™ control algorithm.

To ensure optimal results in this customer scenario, UltraFlex tested the performance of two types of induction coils - a helical induction coil with 2 turns and a C-shape induction coil with 3 turns. At power supply of 5 kW, using the helical coil, it took 13 seconds to reach the brazing temperature and complete the brazing process. At power of 13 kW and using a C-shape induction coil, the heating cycle time achieved was the same.

The test application performed by UltraFlex confirmed the high energy efficiency of UltraFlex induction brazing for the specific customer case and helped identify the most efficient induction heating setup. In addition, the digital control of the UltraFlex induction heating solutions ensures precision and uniformity of the brazing results, with no risk for errors or dependency on the operator skills. Going for an UltraFlex induction heater also ensures an environmentally safe and clean process, thanks to the lack of open flame and noxious emissions.

In summary, UltraFlex's advanced induction heaters are an ideal solution for time-efficient induction brazing of stainless steel assembly, ensuring precision, uniformity, and environmental safety. Contact UltraFlex today to learn more about their breakthrough innovation in induction heating technology.

Find out more at:

https://ultraflexpower.com/

Contact us at:

+1.631.467.6814

uptnews@ultraflexpower.com

UltraFlex Power Technologies

10 Colt Court

Ronkonkoma, NY 11779

Svetla Markova

About UltraFlex Power Technologies:

UltraFlex Power Technologies (ultraflexpower.com) offers the most advanced and innovative digitally controlled induction heating equipment in the industry. Its compact modular and flexible systems are used for a wide variety of induction heating, casting and melting applications.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Application story: UltraFlex's Time-Efficient Induction Brazing for Stainless Steel Tubes here

News-ID: 3153265 • Views: …

More Releases from UltraFlex Power Technologies

Application story: UltraFlex Demos Induction Soldering of Coaxial Connectors to …

UltraFlex Power Technologies has recently demonstrated a cost-, time-, and energy-efficient induction soldering process for coaxial connectors to copper, delivering high-quality results without damaging the dielectric component inside the connectors or separating the 18-micrometer thick copper plate from the substrate.

At the request of a manufacturing industry customer, UltraFlex engineers set up a demo application using brass coaxial connectors and copper discs with a diameter of 10 to 30 cm. They…

Application story: UltraFlex seals with induction Kovar and Borosilicate glass

UltraFlex Power Technologies recently demonstrated the energy-efficient, safe, and clean process of induction sealing for Kovar and Borosilicate glass. As a leading manufacturer of digitally controlled induction heaters, UltraFlex performs demo applications for customers to evaluate heating parameters and results specific to their scenarios.

A customer from the manufacturing and automation industry contacted UltraFlex to achieve a cost-efficient and high-quality hermetical sealing for Kovar and Borosilicate glass using induction. The parts…

UltraFlex Showcases Efficient Induction Brazing in Hydrogen Environments

UltraFlex Power Technologies, a leading manufacturer of digitally controlled induction heaters, recently demonstrated the time- and energy-efficient process of induction brazing in hydrogen environments. This breakthrough solution can help customers achieve increased productivity, enhanced brazing quality, improved energy efficiency, and heightened process safety.

The trial was conducted with five different tube samples provided by a potential customer who sought to replace their old induction heating equipment. The brazing process was conducted…

Application story: UltraFlex demonstrates the use of induction heating for effic …

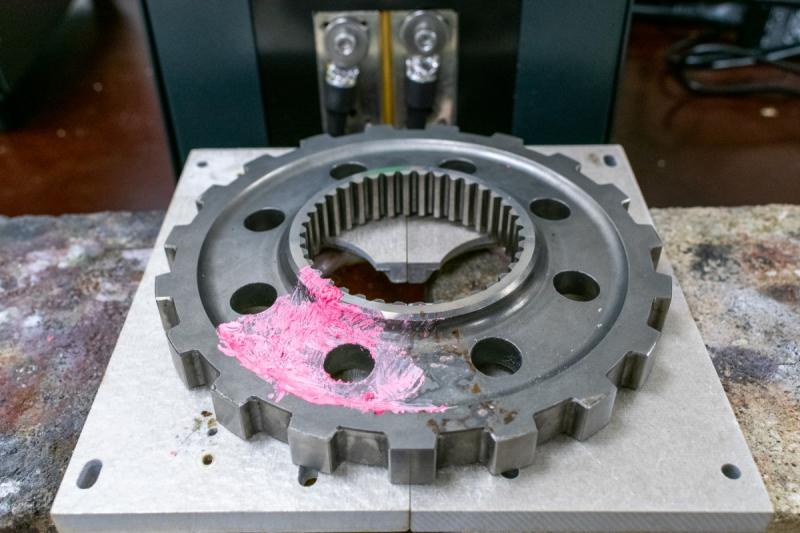

A recent UltraFlex demonstration for a customer looking to increase induction heating capacity showed the efficient use of induction heaters for shrink-fitting of steel parts. Being a leading manufacturer of digitally-controlled induction heating solutions, UltraFlex Power Technologies is frequently doing demo setups evaluating new induction heating customer scenarios, for both new and existing clients.

The customer requesting this demo was an automotive manufacturer producing magnetic steel gear wheels and already using…

More Releases for Induction

Induction Brazing Services Market 2025-2032: Growth Overview, Facts & Figures, S …

As part of our Christmas and holiday season promotion, Businesses can avail discounts of up to 80% on select market research reports. This offer remains valid until 31 December 2025.

The global business landscape is being reshaped by rapid innovation, rising investment and shifting regional dynamics - and at the heart of this transformation lies the Induction Brazing Services Market. From 2025 to 2032, this study delivers key insights, clear segmentation…

Key Trends Influencing the Growth of the Induction Furnace Market in 2025: Major …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

What Is the Expected CAGR for the Induction Furnace Market Through 2025?

The steady increase in the size of the induction furnace market in the past years is evident. There is a projected growth from $1.21 billion in 2024 to $1.27 billion in 2025, marking a compound annual growth…

Core Type Induction Furnace Market Current Scenario and Future Prospects | Globa …

Global Core Type Induction Furnace Market Outlook 2025-2033: Rising Demand and Key Trends:

The latest research study by Infinity Business Insights, titled 'Global Core Type Induction Furnace Market,' offers 142+ pages of in-depth analysis on business strategies adopted by key and emerging industry players. It provides insights into current market developments, trends, technologies, drivers, opportunities, and overall market outlook. Understanding various segments is crucial for identifying the factors that drive market growth. Some…

Induction Heat Treatment Solution for Wind Market Size in 2023 To 2029 | Shiyan …

The Induction Heat Treatment Solution for Wind Industry market report is a valuable resource for clients who wish to forecast investments in emerging markets, expand their market share, or introduce new products. By utilizing established tools and techniques, the report offers a comprehensive and simplified analysis of the multifaceted market. With clear and understandable data presented through the use of graphs and charts, the report is a reliable marketing tool.…

Induction Furnace Melting Aluminum

The induction melting furnace working principle is that the power supply device converts the power frequency 50HZ alternating current into the medium frequency (from 300HZ to 1000HZ), converts the three-phase power frequency alternating current into the direct current after rectification, and then converts the direct current into the adjustable medium frequency current, supplies the medium frequency alternating current flowing through the capacitor and the induction coil, generates high-density magnetic lines…

Induction Furnace Market Foraying into Emerging Economies 2018 to 2028(Based on …

Induction Furnace Market: Introduction

Induction furnace is an electrical furnace in which the heat is generated by induction heat of the metal. Induction capacities range from less than one kilogram to one hundred tonnes, and widely used to melt iron, steel, copper, aluminium and precious metal. The main advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting.

Induction Furnace Market:…