Press release

Application story: UltraFlex seals with induction Kovar and Borosilicate glass

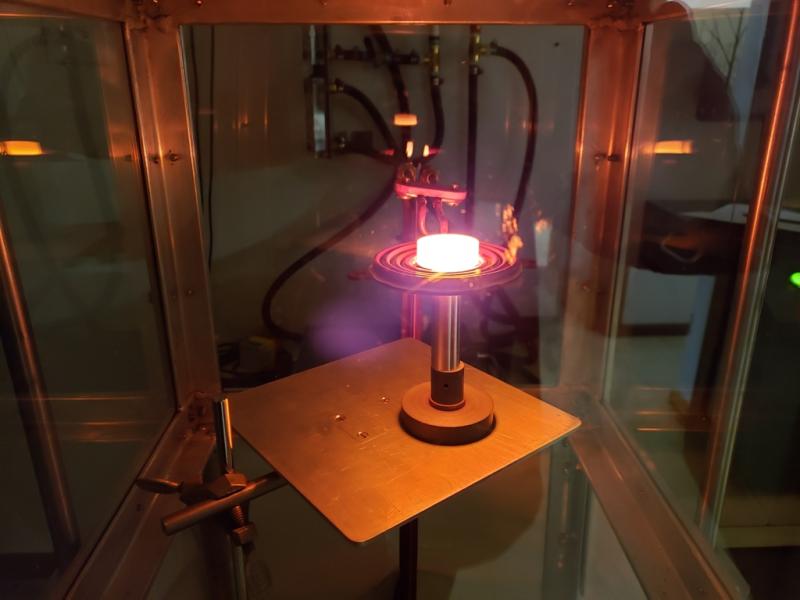

UltraFlex Power Technologies recently demonstrated the energy-efficient, safe, and clean process of induction sealing for Kovar and Borosilicate glass. As a leading manufacturer of digitally controlled induction heaters, UltraFlex performs demo applications for customers to evaluate heating parameters and results specific to their scenarios.A customer from the manufacturing and automation industry contacted UltraFlex to achieve a cost-efficient and high-quality hermetical sealing for Kovar and Borosilicate glass using induction. The parts to be heated were a Kovar cylinder and a glass cylinder, which required reliable sealing without melting or compromise.

To meet the customer's requirements, UltraFlex selected the UltraHeat S induction heater, a compact and efficient 2kW heater that can operate with either water-cooled or air-cooled remote heat stations. The UltraHeat S also features a wide range load impedance matching and is easy to maintain and service.

UltraFlex performed the induction sealing with manual regulation of heating parameters, gradually increasing power from 7% to 68% at a temperature of 50°C. After only two tests, the desired high-quality sealing result was achieved.

The test application confirmed that the 2 kW UltraFlex induction heater was appropriate for the customer's induction sealing scenario. By increasing power and frequency, using an IR sensor, and customizing the induction coil, the process's overall energy and cost efficiency could be significantly improved.

The demo application convinced the customer that induction heating was the most energy-efficient and safe method for achieving the desired sealing result. The digital control of induction heating parameters also enabled full automation, resulting in consistent, and high-quality results independent of operator skills. The customer could increase productivity and ensure a safe process without fumes or noxious emissions due to the lack of an open flame.

Find out more at:

https://ultraflexpower.com/

Contact us at:

+1.631.467.6814

uptnews@ultraflexpower.com

Headquarters

10 Colt Court

Ronkonkoma, NY 11779

Tel: +1 631 467 6814

uptnews@ultraflexpower.com

About UltraFlex Power Technologies:

UltraFlex Power Technologies (ultraflexpower.com) offers the most advanced and innovative digitally controlled induction heating equipment in the industry. Its compact modular and flexible systems are used for a wide variety of induction heating, casting and melting applications.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Application story: UltraFlex seals with induction Kovar and Borosilicate glass here

News-ID: 3068326 • Views: …

More Releases from UltraFlex Power Technologies

Application story: UltraFlex's Time-Efficient Induction Brazing for Stainless St …

The time-efficient induction brazing process for a stainless steel assembly made of low-carbon tubing and fittings has been demonstrated by UltraFlex Power Technologies. UltraFlex is a leading manufacturer of digitally controlled, advanced induction heaters and is frequently setting up demo applications for potential customers looking to evaluate the usage of induction heating for their manufacturing processes.

In this customer scenario, a manufacturer from the automotive industry was looking to replace their…

Application story: UltraFlex Demos Induction Soldering of Coaxial Connectors to …

UltraFlex Power Technologies has recently demonstrated a cost-, time-, and energy-efficient induction soldering process for coaxial connectors to copper, delivering high-quality results without damaging the dielectric component inside the connectors or separating the 18-micrometer thick copper plate from the substrate.

At the request of a manufacturing industry customer, UltraFlex engineers set up a demo application using brass coaxial connectors and copper discs with a diameter of 10 to 30 cm. They…

UltraFlex Showcases Efficient Induction Brazing in Hydrogen Environments

UltraFlex Power Technologies, a leading manufacturer of digitally controlled induction heaters, recently demonstrated the time- and energy-efficient process of induction brazing in hydrogen environments. This breakthrough solution can help customers achieve increased productivity, enhanced brazing quality, improved energy efficiency, and heightened process safety.

The trial was conducted with five different tube samples provided by a potential customer who sought to replace their old induction heating equipment. The brazing process was conducted…

Application story: UltraFlex demonstrates the use of induction heating for effic …

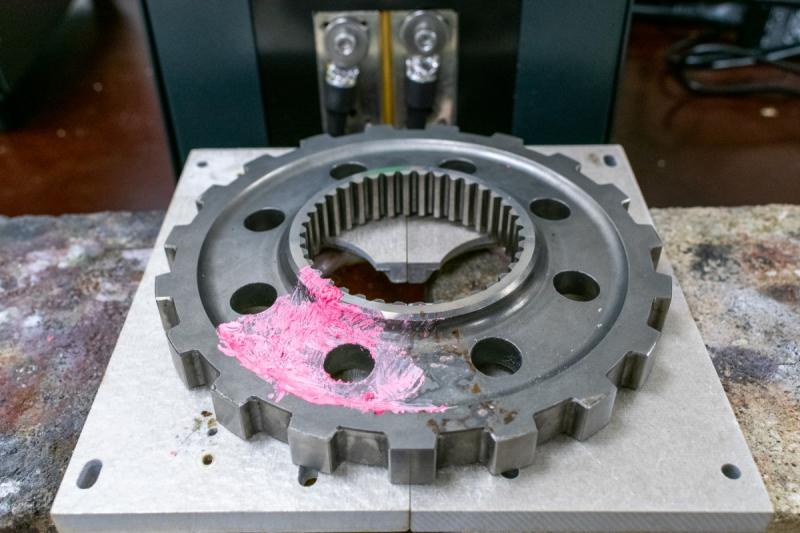

A recent UltraFlex demonstration for a customer looking to increase induction heating capacity showed the efficient use of induction heaters for shrink-fitting of steel parts. Being a leading manufacturer of digitally-controlled induction heating solutions, UltraFlex Power Technologies is frequently doing demo setups evaluating new induction heating customer scenarios, for both new and existing clients.

The customer requesting this demo was an automotive manufacturer producing magnetic steel gear wheels and already using…

More Releases for Kovar

Global Expansion Alloy Market Growth Forecast Report 2026-2032

Global Info Research's report is a detailed and comprehensive analysis for global Expansion Alloy market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the Expansion Alloy market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of…

Kovar Electronic Packaging Market to Witness Robust Expansion by 2025

The latest research report"Global Kovar Electronic Packaging Market Growth 2025-2031" studied by LP Information offers a comprehensive overview of theKovar Electronic Packaging market, providing insights into its drivers, restraints, and future trends. This study employs both primary and secondary research methods to offer unbiased perspectives on the globalKovar Electronic Packaging industry, assisting decision-makers in making informed business choices.

The research employs Porter's Five Forces analysis and SWOT analysis to offer…

Kovar Alloy Market Booming Worldwide( Forecast Period 2023-2029) With Top Player …

The global Kovar Alloy market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Kovar Alloy market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and opportunities of the global…

Kovar Alloy Market Analysis by Emerging Growth Factors and Revenue Forecast to 2 …

LOS ANGELES, United States: The report offers an all-inclusive and accurate research study on the Global Kovar Alloy Market while chiefly focusing on current and historical market scenarios. Stakeholders, market players, investors, and other market participants can significantly benefit from the thorough market analysis provided in the report. The authors of the report have compiled a detailed study on crucial market dynamics, including growth drivers, restraints, and opportunities. This study…

Global Kovar Alloy Market Trends and Forecast Report 2022 | By Players, Types, …

QY Research released a latest market research report on the global and United States Kovar Alloy market and Kovar Alloy market, which is segmented by region (country), players, by Type and by Application. Players, stakeholders, and other participants in the global Kovar Alloy market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region (country),…

1.6 x 1.3 mm – nano quartz crystals up to 52 MHz basic sound

Specialist PETERMANN-TECHNIK offers the world’s smallest mini SMD quartz crystal with 52 MHz basic sound in a 1.6 mm x 1.3 mm ceramic housing.

As always, specialist PETERMANN-TECHNIK is the first to offer innovative products. This time, the new highlight of the “mini SMD quartz crystals” range is the smallest mini SMD quartz crystal in a 1.6 x 1.3 mm ceramic housing with up to 52 MHz basic sound.…