Press release

Spices known from "Die Höhle der Löwen", labeled in a professional way - cab labeling heads, operated by Ankerkraut and GERNEP

The Ankerkraut taste manufacture located in Hamburg is a success. A startup company in 2016, its spices convinced investors on the German "Die Höhle der Löwen" TV show. Enthusiasm for the products has been growing, so has coverage. Mixed spices with illustrious names such as Gipfelstuermer, Annes Liebling, Teufels Kerl or Steuerbord are filled in containers, identified and packed in a modern manufacture facility. GERNEP, a cab partner, has designed technology dedicated to labeling specifically for Ankerkraut. cab IXOR units label thousands of containers fully automated in continuous operation.The collaboration impresses: By operating two to three IXOR in-line the plant, front labels, back labels and sealing labels are applied to a maximum of 8,000 containers per hour. Sensors detect each container. Then the respective labels are applied. On the front of containers, the labels provide a face and promote the brand. Labels applied to the back display the identity of a product. Containers circulated by the taste manufacture must be labeled in accordance with federal and food industry directives. Consumer protection, quality assurance and traceability are key arguments.

Conveyors and distribution centers demand reliable tracking. By adding a print module in advance or subsequent to a label application, flexible data, such as shelf lives, can be printed on the back labels of Ankerkraut products. A flexible kit of basic components enables both glass containers sealed by cork or screw-capped PET containers be printed in the manufacture plant. All machine parameters adjust automatically.

One system, multiple designs

cab IXOR labeling heads apply self-adhesive labels in high quantities quickly and precisely to objects, either in continuous or clocked operation. IXOR is usually assembled by the specialists of the cab TAG ON spin-off on the basis of ten to 20 modules. With the help of this unique construction system, units can be configured specific to a customer while maintaining the high quality of largescale manufacture. Additional equipment for assembly, column and floor stands support IXOR be integrated anywhere to linear or rotary plants. Operators can select from several structural widths.

Performant and reliable

Label webs on an IXOR are fed and set in position by a highly dynamic servo controller. A high-torque external rotor drive moves any roll in continuous operation. Label webs are wound reliably. The control unit integrates to the chassis. By assembling a sensor to the peel-off plate of IXOR, smallest differences in height can be detected on webs in motion. Each label to be transferred is verified. A touch display with symbols is provided. The web interface enables remote control, using a tablet, smartphone or PC.

Close to customers

Labeling spice containers with cab units: What are the experiences so far? And how did the coordination with Ankerkraut go? Mr. Martin Hammerschmid, Managing Director of GERNEP, provides information.

What was the process like from the initial contact with the customer to the ready-made machine?

Hammerschmid: "We had been recommended to Ankerkraut. In general, when marketing and technology meet, you have to find a compromise. In this case, two passionate companies coincided. There were months of mutual recommendations between the first meeting and the final design. We love challenges and put all efforts into the machine. The result is very satisfactory for all the parties involved."

What role does labeling play in your operations?

Hammerschmid: "Labeling has always been an essential product feature. We are very experienced in this and rely on partners. Customers profit from a wide range of solutions. Requirements on the technology provided by cab had been defined from the start as precise, stable, rugged and future-proof. Digital interfaces must ensure signal exchange with the higher-level plant control unit, other machines or components. The IXOR units meet all the requirements for the upcoming years. They are established on the market."

How did you become aware of cab?

Hammerschmid: "cab had been known to us for some time to be very innovative in label printing systems. At a point some years ago, cab added to its range of products systems for dispensing self-adhesive labels in rotary and linear plants. We at once got the idea that these will fit perfectly with our solutions. We got in contact and accompanied the development of IXOR systems. Our joint working has been very complementary. It is a pleasure to collaborate with cab. I am sure our partnership will be a long-term one. This is a win-win situation for cab, GERNEP and the customers."

Customized IXOR configuration

Each IXOR operation follows individual needs. In order to evaluate all such requirements and transfer them to the specifications of IXOR, cab has set up a specified contact and sales structure: www.tag-on.de/en

Video of this application: www.cab.de/en/gernep

cab partner in this project: www.gernep.de/en

Presscontact: Guntram Stadelmann, cab Produkttechnik GmbH & Co KG, Wilhelm-Schickard-Str. 14, 76131 Karlsruhe, Phone: +49 721 6626-285, Fax: +49 721 6626-249, Email: g.stadelmann@cab.de

About: cab is Europe's biggest manufacturer of label printing systems. The range of devices includes solutions for marking individual components, units, products or packaging. Healthy global growth, pioneering technologies, products designed according to the needs of operators and the competent support of all customers are prior goals of the company. Employees at locations in eight countries and more than 800 distribution and service partners around the globe are there to meet the targets. www.cab.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Spices known from "Die Höhle der Löwen", labeled in a professional way - cab labeling heads, operated by Ankerkraut and GERNEP here

News-ID: 2663442 • Views: …

More Releases from cab Produkttechnik GmbH & Co KG

Outstanding innovative strength - cab Produkttechnik awarded TOP 100

- Selection process on the basis of more than 100 test criteria

- Fourth decoration since 2017

- Award ceremony to be held in June in Heidelberg

cab has once again been awarded TOP 100. This indicates that the company belongs to Germany's most innovative SME. Christian Wulff is going to congratulate cab face-to-face at the award ceremony during the German SME Summit on June 26, 2026, in Heidelberg. The former German Federal Minister and Lower…

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

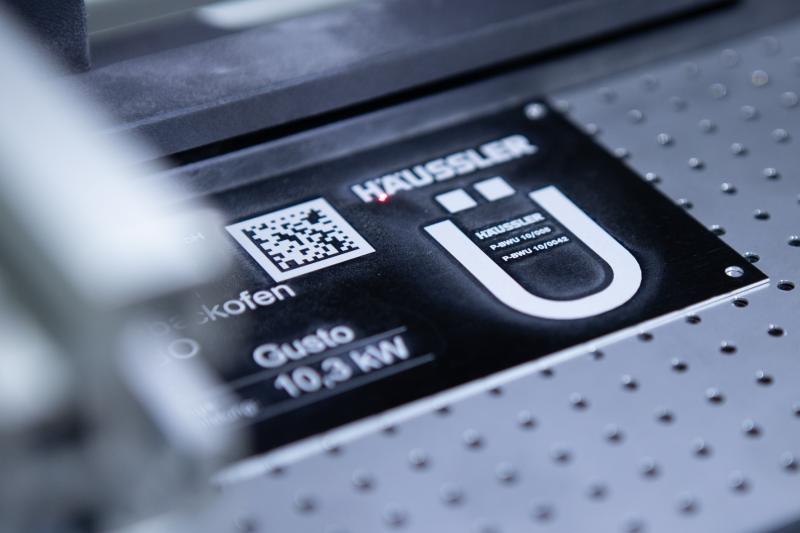

Tradition meets modern - Typeplate marking in a baking village

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company's own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills. Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab…

cab and LRS unveil breakthrough label printing integration

cab and LRS have announced a major advancement in industrial label printing. As of the latest firmware 5.47.5 release, cab printers now fully support VPSX® bi-directional PJL delivery - unlocking a new era of precision, reliability, and flexibility for high-volume labeling environments.

This integration empowers organizations to streamline operations with intelligent label recovery and reprint capabilities. Whether due to a power outage or operator error, large batches of labels…

More Releases for IXOR

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

Smart Packaging - Cobot, take over label!

cab solutions have been enabling reliable labeling for more than 45 years. Companies specialized in the packing of industrial and consumer goods appreciate the wide range of operations possible with the units and systems, as well as their integrability to fully automatic packing lines. At the cab Fachpack booth, a collaborative robot application complements proven disciplines of labeling.

Already in 2012 cab demonstrated with an early HERMES system how to apply…

Feeding, labeling and packing PCR tests - When precision is the target

PCR methodology has been established when detecting SARS-CoV-2 infections. Corresponding test kits are used by doctors and mobile medical service providers, pharmacies and labs. They are packed in fully automated plants and identified according to pharmaceutical regulations. The Kraus Maschinenbau company specializes in systems as required. cab prepares IXOR labeling heads and CEON high-tech sensors integral to packing lines to provide reliable, accurate label applications.

Specified machines are constructed, assembled and…

Covid-19 rapid test: a combination of machines providing, labeling and packing

Corona presents challenges to the country. Test cassettes are needed to detect antibodies within few minutes using a blood sample. Strong demand for the cassettes results in fully automated plant manufacture. The Kraus Maschinenbau company specializes in feeding solutions as required. Complex packing machines have been designed by the staff, developed and manufactured on behalf of Senova Immunoassay Systems. Test cassettes and strips are taken over from prior processes and…

Familiar with printing systems from anywhere at any time - cab trade show twin l …

cab customers are technophiles. They call for quick and easy orientation while in search on the Internet. At this point, cab launched the entirely equipped cabFAIR showroom. Only a device providing Internet access and a web browser are required to circulate freely within it. Models can be viewed 360°, information or videos called up. cab experts reply to questions by chat or in live meetings.

On startup, the cabFAIR user interface…

Automated labeling: new benchmarks set by a print module, a labeler and a sensor

If planning the purchase of a system for printing and applying labels on products or their packaging in production lines, the basic question is how to implement the application particularly smart and economical? The PX Q print module and the IXOR labeling head with a CEON high-tech sensor combine successfully in industrial and food production, tamper evidence, container filling in rotary machines and logistics.

The PX Q integrates to plants in…