Press release

Covid-19 rapid test: a combination of machines providing, labeling and packing

Corona presents challenges to the country. Test cassettes are needed to detect antibodies within few minutes using a blood sample. Strong demand for the cassettes results in fully automated plant manufacture. The Kraus Maschinenbau company specializes in feeding solutions as required. Complex packing machines have been designed by the staff, developed and manufactured on behalf of Senova Immunoassay Systems. Test cassettes and strips are taken over from prior processes and are jointly packed in pouches. In close cooperation with cab, a PX Q print module and an IXOR labeling head integrate for labeling the pouches uniquely in accordance with pharmaceutical regulations.Customized solutions

Joachim Kraus founded his company in 2008. Friction feeders are his subject. In addition to packages no more than 30 mm thick, other flat products such as package inserts, folding box blanks or brochures can be fed or separated. Solutions are put into operation customer-specific wherever, in addition to standard feeding or separation, products must be packed, marked, labeled, tested or counted. cab units have proven effective in Kraus machines designed for applications requiring label printing. In the Senova project, Mr. Kraus decided for cab in labeling as well. Why, he tells in an interview.

- Which factors have been decisive for choosing cab?

Kraus: In the end, human beings make the difference. There has been a close relation to Michael Kuerner (cab consultant for systems dispensing printed labels) for many years. He has not only been selling us devices, but also provides technical competence on a high level. If anything does not work a 100 percent, and this might happen in project business, he takes a wrench in his own hands to find a solution. We very much appreciate this pragmatism.

- What about the technical aspects?

Kraus: In practice, we soon got aware of the high quality of the cab units. They provide a rugged construction and all the interfaces necessary to realize projects even related to Industry 4.0. In plants, they operate autonomous, interact among each another, with host computers or the plant control unit by cable or WLAN. MQTT assures communication, the industrial standards Modbus, OPC UA and EtherNet/IP as demanded from many customers are supported. To integrate the units in our machines mechanically, cab provides accessories and the required aids for assembly. In a series of machines dedicated to antibody tests we will now deliver already the second one to Senova. As regards the initial one, cab evaluated all our requirements very quickly and transferred them to the specifications of the printers and labeling units. As a result, we got exactly the product we required. In cases Mr. Kuerner or any other cab specialist are not available in person at short notice, cab’s technical hotline supports. We have made positive experiences on this as well.

- An overall concept, as it is now being implemented, had not been on target initially.

Kraus: That‘s right. Senova initially asked for an individual solution to feed plastic pouches. In a project meeting, we jointly analyzed the subject. We agreed that an overall concept consisting of several processes and machine components makes sense. Considering the current state of Corona worldwide, you can certainly imagine that time was short for putting all this in operation. Our constructors and parts manufacturers operated under high pressure in shifts. The machines are assembled, initially operated and accepted by the customer inhouse prior to delivery. Quick decision paths between the construction, purchasing and assembly departments enable us to deliver at short notice if required. This was also a clear advantage here.

- Tell us about the operating principle of the machine.

Kraus: In prior processes, the raw materials of test strips are separated and the strips inserted to cassettes. A friction feeder separates ready-made plastic pouches. The test cassettes and the prepared pouches are transferred to the packing machine. The PX Q prints product-specific data on labels. The printed labels are transferred to IXOR to be applied on the pouches. At this, the pouches remain in motion on the conveyor belt. The labeled pouches are kept open by vacuum, test cassettes including strips are inserted, the filled pouches thermally sealed and finally collected. Product transfer from one process to the next is controlled by PLC, so are all the processing steps.

- How important is the labeling?

Kraus: Subsequent to the blood sample, the antibody test provides information on whether there is a Covid-19 infection, the person tested is immune or has not yet come in contact with the virus. The test cassettes are pharmaceutical products. Each cassette must be clearly identified compliant to the regulations on serialization and traceability and packed in accordance with pharmaceutical standards.

Printing

PX Q is a module designed by cab for pure continuous printing in industrial environments. Several thousand labels can be printed per day and the printed labels in subsequence provided, for example to be applied by a labeling head, in this case an IXOR. Printed labels are provided to the right or left. The print module is 25 cm wide, 30 cm high and less than 40 cm deep, making it easy to integrate. The print method is thermal transfer. Depending from the field of operation, thermal markings remain legible during processing and storage, resist extreme temperatures, liquids and solvents. Sharp-edge definition and high contrast enables even smallest information be verified on a label.

Labeling

Printed labels are applied by IXOR to products exactly on position. A high-torque servo engine allows conveyor belts running with 200 meters per minute even in continuous operation. Depending from the device configuration, the label material and the size of a label, a maximum of 2,400 labels per minute can be applied synchronous to the speed of the product. The device control is part of the base unit. Its casing only 54 mm deep, IXOR accommodates in small installation space.

Detecting

To detect even smallest height differences of 1/100 mm on material webs in motion, the CEON high-tech sensor must be assembled as close as possible to the peel-off plate on the IXOR. At this spot, the effect of material stretching is low and the detection of labels peeled off guaranteed. As the label web remains tight, each label is stabilized while detected and transferred. CEON proves strong in particular with transparent adhesive labels in no-label look, very thin opaque or metallic materials.

Video of this application: www.cab.de/en/kraus-video

Further cab case studies on the web: www.cab.de/en/news/case-studies

Presscontact: Guntram Stadelmann, cab Produkttechnik GmbH & Co KG, Wilhelm-Schickard-Str. 14, 76131 Karlsruhe, Phone: +49 721 6626-285, Fax: +49 721 6626-249, Email: g.stadelmann@cab.de

About: cab is Europe’s leading manufacturer of devices and systems to label individual components, units, products and packaging. Healthy global growth, both technical and functional lead and competent customer support are prior goals of the company. There are 400 employees in Germany and in seven subsidiaries abroad as well as 820 distribution partners in more than 80 countries to meet the targets. www.cab.de/en

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Covid-19 rapid test: a combination of machines providing, labeling and packing here

News-ID: 2149127 • Views: …

More Releases from cab Produkttechnik GmbH & Co KG

Outstanding innovative strength - cab Produkttechnik awarded TOP 100

- Selection process on the basis of more than 100 test criteria

- Fourth decoration since 2017

- Award ceremony to be held in June in Heidelberg

cab has once again been awarded TOP 100. This indicates that the company belongs to Germany's most innovative SME. Christian Wulff is going to congratulate cab face-to-face at the award ceremony during the German SME Summit on June 26, 2026, in Heidelberg. The former German Federal Minister and Lower…

Smart, flexible, cost-effective - print and apply solutions @LogiMAT 2026

Label printing systems by cab have been enabling reliable marking for more than 50 years. Industrial companies appreciate the wide range of possibilities in incoming goods and stock, picking and packing, transport and shipping. Smart and cost-effective options will complement tried and tested marking disciplines at the cab booth.

cab will be presenting labeling heads designed for applying pre-printed self-adhesive labels fully automatically in linear or rotary plants, synchronous to the…

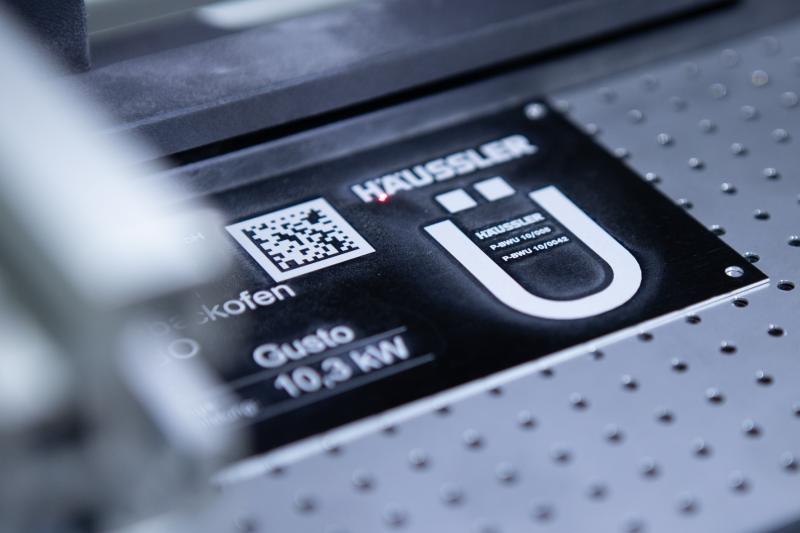

Tradition meets modern - Typeplate marking in a baking village

Karl-Heinz Häussler deals with grinding, kneading and baking. In the company's own baking village, around 100 employees design, manufacture and sell high-quality woodburning ovens and cookers, dough kneading machines, pasta makers and grain mills. Hobby bakers and professionals find guidance and inspiration in baking lessons and seminars. Every unit circulated by Häussler must be clearly identified in accordance with industry regulations. The typeplates are marked in reliable manner by cab…

cab and LRS unveil breakthrough label printing integration

cab and LRS have announced a major advancement in industrial label printing. As of the latest firmware 5.47.5 release, cab printers now fully support VPSX® bi-directional PJL delivery - unlocking a new era of precision, reliability, and flexibility for high-volume labeling environments.

This integration empowers organizations to streamline operations with intelligent label recovery and reprint capabilities. Whether due to a power outage or operator error, large batches of labels…

More Releases for Kraus

Weber Kraus Advances Trading Tools and Market Analytics as Platform Capabilities …

Introduction

Weber Kraus continues to develop its crypto trading platform with a sustained focus on advancing trading tools and market analytics designed to support more structured and informed participation. As digital asset markets evolve and user behavior becomes increasingly data-driven, platforms are expected to provide analytical depth while maintaining clarity, stability, and operational discipline. The company's latest platform update reflects an emphasis on refining internal systems that support analytical insight without…

Weber Kraus Reports Sustained International Platform Expansion Amid Rising Globa …

Weber Kraus has announced continued platform growth across international trading markets, reflecting steady expansion aligned with increasing global participation in digital asset trading. As cross-border market access becomes a central expectation among traders, platforms are being evaluated on their ability to deliver consistent performance, transparent operations, and reliable user experiences across regions. The latest update highlights the platform's measured approach to growth, emphasizing operational stability and structured development rather than…

Brass Faucets Market Key Regions, Major Manufacturers Performance | Kraus, JOXOD …

Infinity Business Insights posted a brand-new business studies report Brass Faucets Market in its database. This is a modern report, such as the current COVID-19 impact on the market. The global Brass Faucets Market report provides enormous records about Brass Faucets Market with the resource of fragmenting the market into numerous segments. In the global Brass Faucets Market studies report, multiple crucial factors such as regional market insights, area-sensible trends,…

CNG Dispenser Market | Censtar, Compac, FTI, Kraus, Lanfeng, Sanki, Scheidt & Ba …

Global CNG Dispenser Market: Overview

CNG, short for compressed natural gas, is an alternative green fuel gotten from natural gas under pressure so that it remains odorless, clear, and non-corrosive. Beside they are also cheaper and efficient than the conventional petrol and diesel used to run vehicles. CNG is primarily comprised of methane. Just like gasoline, it produces engine power once it is combined with air and fed into the combustion…

Waters & Kraus Congratulates TAF Whistleblower of the Year Allen Jones

Taxpayers Against Fraud Education Fund Honors Waters & Kraus Client for Fighting Medicaid Fraud by Drug Company

WASHINGTON, DC — September 17, 2012 — Last Thursday night, the non-profit public interest organization Taxpayers Against Fraud Education Fund (TAF) honored Waters & Kraus client Allen Jones for blowing the whistle on alleged fraud and illegal kickbacks by Johnson & Johnson subsidiary, Janssen Pharmaceutical, Inc. Mr. Jones, a former Pennsylvania healthcare fraud investigator…

Waters & Kraus, LLP Welcomes Two New Litigators

Waters & Kraus, LLP, a leading national plaintiffs’ firm, is pleased to announce two new additions to our practice:

WM. Paul Lawrence, II, of counsel

David Bricker, of counsel

Bringing a wealth of qui tam litigation experience to the firm, Paul Lawrence broadens our practice and deepens our commitment to excellence in legal representation of plaintiffs in complex fraud cases and class action litigation. He is a frequent speaker for…