Press release

Ceramic Polymer coating for drinking water applications: Restoration of pipework according to Promotec-system

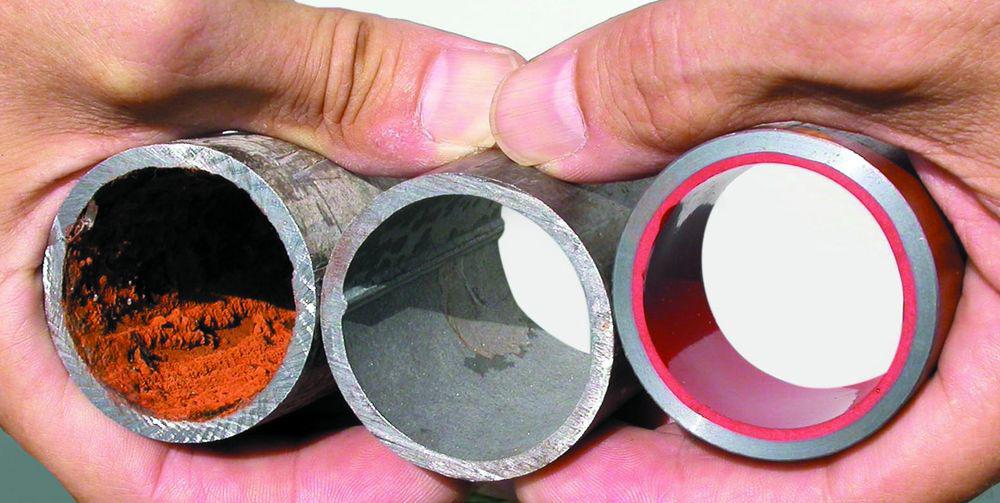

The company Sancor GmbH in Hohenzell/Austria was established in 2007 and is specialized in restoration of built-in pipework systems. The Owner Mr. Veren Nenov and his competent team use the Promotec-system from the Swiss enterprise Promotec Service GmbH successfully, which is a unique and patented procedure for the cleaning and coating of defective pipes without extensive and costly replacing.First of all, corroded and calcified pipes of steel and copper for e. g. drinking water, gases, sprinkler installations or compressed air with a diameter of 5 mm up to 75 mm are cleaned by the special wet cleaning treatment gently and thoroughly. By flushing in both directions with fine, swirling washing particles the complete inner surface is being reached and smoothed down properly. No shadow zones occur where rust could remain and spread out afterwards. After mechanical drying the pipes are coated internally with a seamless layer. The application is achieved by a pressure assisted vacuum process. After curing the coating result is examined with a flexible endoscope.

For the restoration of drinking water pipes Sancor GmbH uses continuously our premium system Proguard CN 200, which provides superior physical properties in comparison to other epoxy coatings. Thus, our product is optimally qualified for this specific field of application.

Deciding reasons to employ Proguard CN 200

for these special applications:

• Drinking water approval (KTW - German stan-dards) for operating temperatures up to 85°C

therefore applicable for hot water pipes.

• Passed test series DVGW-W270 (German standards) – Growth of microorganisms, biofilm. Proguard CN 200 is even in microbiologigal aspects suitable for drinking water applications.

• Low viscosity

after slightly warming the product is adequately free-flowing, spreads easily and evenly all-over inside of the pipework, achieves constantly excellent results in final examinations.

• Fast curing times

already after 24 hours of curing the pipe can be controlled and flushed.

The Ceramic Polymer GmbH produces high-performance coatings with integrated micro ceramic particles for different fields of application. The properties of the ceramic – chemical resistance, abrasion resistance and weathering stability – justify the high quality of our coating systems. By extra integration of microscopic special particles, we generate coating products which provide the highest protection properties. We invest constantly in specific test series to provide high quality, solvent-free coatings and guarantee the safety for drinking water and food applications. The necessary criteria of the German Federal Health Office are fulfilled in different groups. Thus, our products are usable in scope of drinking water (German standard KTW). They show for instance hardly verifiable chlorine absorption or release of substances, which would promote microbiological growth and impair the drinking water.

Ceramic Polymer GmbH

Stephanie Wuensch

Daimlerring 9

D-32289 Roedinghausen

Phone: +49 (0) 5223 / 96 276-0

Email: info@ceramic-polymer.de

Web: www.proguard-coatings.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ceramic Polymer coating for drinking water applications: Restoration of pipework according to Promotec-system here

News-ID: 263987 • Views: …

More Releases from Ceramic Polymer GmbH

Ceramic Polymer: NORSOK M-501 - The Coatings for Offshore Requirements

New Product Line for demanding Offshore Areas

Regarding suitability of protective coatings for the offshore industry, the system classification

NORSOK M-501 is the most important standard for the assessment of product reliability.

The specific coatings feature extreme mechanical resistances and provide long-lasting corrosion protection

at durable sea water and weather exposure also within the tidal and splash zone.

NORSOK M-501, Edition 6 - System 1 and System 7B

Ceramic Polymer provides high-quality 2…

Ceramic Polymer: 15 Dump trailers coated with PROGUARD CN-1M – durable protect …

Up to now, the high-performance coating PROGUARD CN-1M was used for 15 special dump trailers from OptiTwin GmbH, manufacturer of utility vehicle for agriculture industry. The highly resistant internal coating was applied by the experiences partner, Reinken Company for blasting and coating technology located in Garrel/Germany. PROGUARD CN-1M provides long-term protection for the aluminum substrates against enfluences of liquid manure and solid animal residues.

The specific dump truck ”OptiTwin“…

Ceramic Polymer: Coating of copper block heat exchanger by flood method with low …

The company “Zacosin® the surface experts”, located in Gladbeck/Germany, is specified on surface protection of different devices and plant components as well as the wide scope of thermal process technology. For several years, the product PROGUARD CN-1M is applied for new coating or repair of coolers and water chambers made of copper, steel or cast aluminum. Furthermore, the system is used as sealing of thermal coated, enameled heat exchanger.

The…

More Releases for Proguard

Chesterton's new Proguard 169 Plus - Polyurethane Topcoat without diisocyanate t …

For aggressive atmospheric conditions, Chesterton provides a premium topcoat with excellent corrosion protection properties.

Proguard 169 Plus, from the Ceramic Polymer product line, is a 2K polyester-reinforced polyurethane topcoat with excellent color retention, UV stability and mechanical strength.

The product is designed as a topcoat for steel structures, tanks, pipelines, bridges and offshore installations. It is applied as a single coat using various application methods and is available in RAL and…

Stainless Steel Separator renovated effectively with Proguard CN-OC - durable Pr …

Barcelona: A salt mine near the Catalan capital city uses for crystallization of salt a specific separator of stainless steel double chambers. Even after 2 years of operation the stainless steel substrate showed heavy corrosion damages; induced by the highly aggressive concentration of sodium chloride in the water at a constantly temperature of 45 �C.

After 2 years of service severe pitting corrosion was detected especially at corners and edges of…

Ceramic Polymer: 15 Dump trailers coated with PROGUARD CN-1M – durable protect …

Up to now, the high-performance coating PROGUARD CN-1M was used for 15 special dump trailers from OptiTwin GmbH, manufacturer of utility vehicle for agriculture industry. The highly resistant internal coating was applied by the experiences partner, Reinken Company for blasting and coating technology located in Garrel/Germany. PROGUARD CN-1M provides long-term protection for the aluminum substrates against enfluences of liquid manure and solid animal residues.

The specific dump truck ”OptiTwin“…

Ceramic Polymer: The coating PROGUARD CN200-LV2 for push floors of feeding stati …

Hohenzell/Austria: The company “Korrotech - Beschichtungstechnik GmbH” is specialized on professional blasting and coating operations. For the well-known German manufacturer of biogas plants and equipment, “Schmack Biogas Komponenten GmbH”, specific slide bars for push floors of the feeding stations PASCO were coated with the system PROGUARD CN200-LV2.

This coating product offers beside excellent stabilities against chemicals and high operating temperatures an extremely high abrasion resistance. Therefore, it is optimally qualified…

Ceramic Polymer - Premium Coating „Proguard CN-1M“ – acid-proof at pH-valu …

The coating systems of Ceramic Polymer GmbH are applied for complex agricultural applications due to extreme chemical and abrasion resistances. The physical properties of the products are deciding for a durable value preservation of different buildings within agrarian economy.

Concrete and steel constructions of digesters, septic tanks, slurry reservoirs, fodder fermenting silos, biogas and composting plants as well as wastewater systems are constantly exposed to high chemical attack by acidic…

Ceramic Polymer high-performance coating “Proguard VEG“ – resistant agains …

Last month a partner from Ceramic Polymer GmbH, Witaco-Tanktechnik from Hameln/Germany, has conducted an internal coating with highest product requirements. The trailer has a capacity of 79 cu. meters and is destined for the transport of 20% hydrochloric acid. There are very few coatings available, which show a sufficient resistance against such aggressive and highly corrosive liquids.

Due to the combination of high quality resins and selected fillers, the Ceramic…