Press release

Hebei biomaterials plant selects Siveco China for Asset Maintenance Management project

Hebei CASDA Biomaterials Co., Ltd., part of specialty materials leader Arkema Group, has selected Siveco China to implement its Maintenance 4.0 solution for Asset & Maintenance Management. The decision was made after a comprehensive selection process and careful consideration of various suppliers.Established in January 2010, Hebei CASDA Biomaterials Co., Ltd. joined Arkema Group in January 2012 with a registered capital of 4.19 million RMB. The plant covers an area of 338 acres and employs more than 420 people. As a leading manufacturer in the sebacic acid industry, CASDA benefits from over 50 years' experience. Its main product, sebacic acid, is bio-based, has high purity and offers stable supply. It is mainly used as raw materials for cold-resistant plasticizers, synthetic resins, synthetic fibers and nylon. It is sold in over 20 countries across Europe, America and Japan.

The chemical industry is currently undergoing a transformation driven by business growth, stricter regulations and digitalization. CASDA pays foremost attention to asset maintenance management in order to ensure the safe and reliable performance of the plant and to control life-cycle cost. Maintenance represents a major workload of high complexity, requiring advanced skills and tools. CASDA decided to embrace the trend of informatization to tackle its maintenance improvement needs.

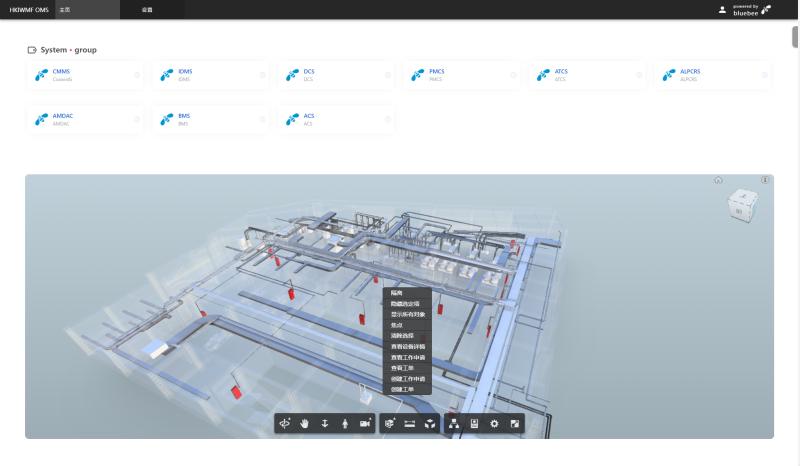

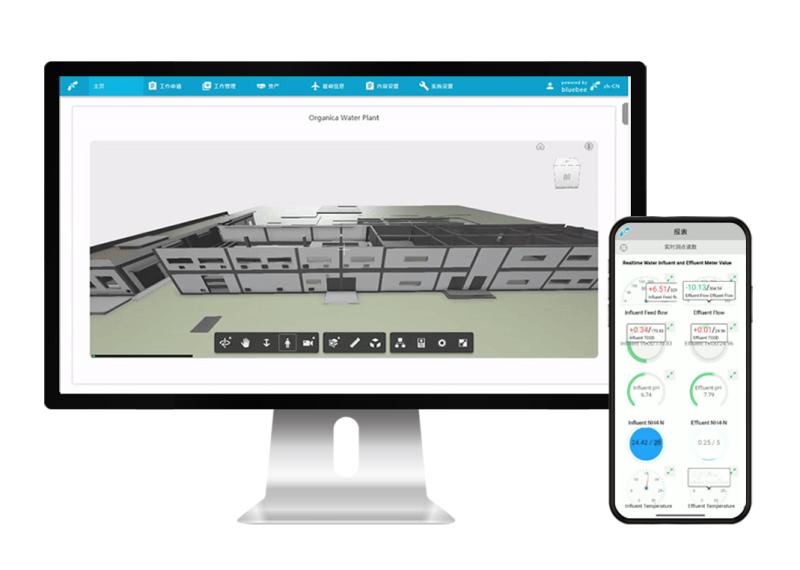

Siveco China was selected in part thanks to its successful track record working for other Arkema and Bostik plants in China and more generally its experience with large chemical companies. CASDA will deploys Siveco China's Maintenance 4.0 solution based on the Coswin 8i CMMS and the bluebee® mobile solution. The main focus of the project is to help the plant improve its maintenance planning, ensure full traceability of work, manage spare parts and overall enable a feedback loop from workers to managers for better decision making. The implementation methodology is built upon the ISO 55000 Asset Management standard. The project was launched on December 6, 2021, date on which the Siveco China project team came on site to conduct initial training and implementation study.

Siveco China Head Office

Unit J, 20th floor, Zao Fong Universe Building

No.1800 Zhong Shan Road (W)

Shanghai 200235 - PR China

About Siveco China

Siveco China (www.sivecochina.com), founded in 2004, is a pioneer in the development of Smart Technologies for the Operation & Maintenance of infrastructures and industrial plants, with a focus on mobile solutions "for the worker of tomorrow".

Long before the terms "smart" and "4.0" were coined, Siveco has been helping clients optimize the lifecycle of their assets and ensure regulatory compliance using IT. Based on a long experience of "maintenance with Chinese characteristics", the company has designed a unique approach combining expert maintenance consulting and technological innovation. Smart O&M solutions developed in Siveco's R&D center in Shanghai cover Asset Management, Maintenance 4.0, Risk Prevention and HSE, utilizing Mobility, IoT, BIM, AR and AI technologies.

Siveco China has over 900 customer sites all over Greater China and on the Belt & Road, including ABB, Baosteel Metal, Beijing Environment, Capital Water, Carrefour China, CEPSA, CNEEC, CNOOC, COSCO, Fushun Mining, Engie, Everbright, GE, New World Development, Saint-Gobain, Shell, Suez NWS, Yingde Gases, Zhongshan Water etc. The company boasts a growing export business, working alongside Asian EPC companies and with international clients in Southeast Asia, the Middle-East and Africa.

Siveco China has won numerous awards, most recently the prestigious Brilliant 40 Years prize by the China Electric Power Equipment Management Association, Top Ten Enterprise for Asset Informatization Service by the and the China Association of Machinery Equipment Maintenance and Renovation (CAMER) and Best Industrial Software 2017 by Control Engineering China. Previous awards include CHaINA Supply Chain Excellence Award 2013 and Engineers' Choice Awards by Plant360 in three categories in 2015.

Siveco is ISO 9001-certified by Bureau Veritas for its entire scope of business. The company is headquartered in Shanghai, where it also operates its R&D center, and has offices in Hong Kong. Siveco China is a subsidiary of Siveco Group, a European pioneer in computerized maintenance management systems (CMMS).

Siveco China publishes the "Smart Operation & Maintenance - for the worker of tomorrow" newsletter dedicated to maintenance management, bilingual English and Chinese, available to subscribers and online.

Contact

Tel (China mainland): 4006 300 213

Tel (overseas): +86 21 64403226

E-mail : info@sivecochina.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Hebei biomaterials plant selects Siveco China for Asset Maintenance Management project here

News-ID: 2539723 • Views: …

More Releases from Siveco China

ESG & decarbonization in operations: the digital gap

(This article was previously published in the December 2022 issue of APUEA magazine.)

ESG (Environmental, Social, and Governance) is a framework that helps stakeholders understand how a company is managing risks and opportunities related to environmental, social, and governance criteria. Looking at ESG from a plant management's perspective: Environmental includes energy, water and waste. Social covers safety, first and foremost. Governance consists in complying with regulations and best practices, as well…

The Future of Operation & Maintenance

Media hype has led us to believe that technology would soon revolutionize maintenance. Dreams of flying robots, video game-like smart glasses, flashing digital twins, often hold the sad promise of getting rid of maintenance people altogether. The reality remains that the more automated, the more sophisticated the systems, the more demands are put on maintenance people and their skills. The problem is compounded when this glorious technology did not address…

On the Belt & Road with clients and partners in Thailand

Thailand is a priority for Siveco China's development in Southeast Asia owing to the country's well-developed industry and growing infrastructure development. During October, our Managing Director visited local clients and partners.

Please enjoy our postcards from Thailand!

Several new partnerships and projects were also launched during this period - more on this later!

Siveco China is active all over Asia with projects not only in Thailand, but also in Brunei, India, Indonesia,…

Feedback on "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thail …

Siveco China organized a team of high-profile speakers at MIRA SUBCON EEC, Thailand's Leading Industrial Solutions Event, held on August 26 in Pattaya. The session was hosted by the Asia Pacific Urban Energy Association (APUEA). Under the theme "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thailand 4.0", the workshop aimed at sharing practical experience for the local market.

After an introduction by APUEA's Executive Director Peter Lundberg, the event…

More Releases for Maintenance

Maintenance software Wartungsplaner optimizes your maintenance

Master maintenance management with digital maintenance planner

The maintenance planner from Hoppe Unternehmensberatung has been used in the manufacturing industry for many years to keep machines and equipment running smoothly.

The wartungsplaner https://www.Wartungsplaner.de/ optimally organizes interlinked processes, from inspection to predictive maintenance to servicing.

The recurring maintenance dates need to be controlled and monitored.

It is not always easy to keep track of inspection regulations and inspection deadlines. Regardless of whether you are…

Predictive Maintenance Market 2031: Proactive Maintenance Advances

Predictive Maintenance Market Market Scope:

Global Predictive Maintenance Market size was valued at USD 5.77 Billion in 2022 and is poised to grow from USD 7.57 Billion in 2023 to USD 66.46 Billion by 2031, at a CAGR of 31.2% over the forecast period (2024-2031).

Access the full 2024 Predictive Maintenance Market report for a comprehensive understanding @https://www.skyquestt.com/report/predictive-maintenance-market

The study of the global Predictive Maintenance Market is presented in the report, which is…

Building Maintenance Service Market Massive Growth Opportunity Ahead | Pacific M …

The latest study released on the Global Building Maintenance Service Market by HTF MI Research evaluates market size, trend, and forecast to 2030. The Building Maintenance Service market study covers significant research data and proofs to be a handy resource document for managers, analysts, industry experts and other key people to have ready-to-access and self-analysed study to help understand market trends, growth drivers, opportunities and upcoming challenges and about the…

Maintenance planner - Planning maintenance becomes easy with these tips

Have you had enough of chaotic maintenance schedules and inefficient processes?

Then the deluxe maintenance planner https://www.Wartungsplaner.de is just the thing for you! With this tool, you can organize and plan your maintenance work optimally. Find out why efficient organization is so important and the benefits of using the maintenance planner. You will also receive valuable tips for optimal use and effective planning of maintenance work.

Why Maintenance Planner?

The efficiency and…

DOCUFY Maintenance Manager simplifies maintenance

DOCUFY presents a new cornerstone of its software suite in the form of DOCUFY Maintenance Manager (DMM), allowing companies to integrate their information and sustainably boost their success through intelligent knowledge utilisation. Through digital integration of periodic maintenance tasks with machine data, the DOCUFY Maintenance Manager opens the door to forward-looking, resource-optimised maintenance. In practical terms, this means that service representatives can access a display of the precise machine variant…

Preventive Maintenance Software Future Prospects Hippo CMMS Software, MAPCON Tec …

Latest release from CMI with title Preventive Maintenance Software research Report 2019-2026 (by Product Type, End-User / Application and Regions / Countries) provides an in-depth assessment of the Preventive Maintenance Software including key market trends, upcoming technologies, industry drivers, challenges, regulatory policies, key players company profiles and techniques. Global Preventive Maintenance Software Market study with 100+ market data Tables, Pie Chat, Graphs & Figures is now released BY CMI.

Global Preventive…